Composition, foam, and article made therefrom

A foam material and composition technology, applied in the field of foam material composition, foam material and products, can solve the problems of low water absorption, lack of functional foam material performance, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation of heat-expandable microspheres may be any method that includes the step of polymerizing monomers in aqueous suspension in the presence of a blowing agent, and is known, as in earlier publications, e.g., U.S. Pat. No. 3,615,972, WO99 / 46320 and WO 99 / 43758, the contents of which are hereby incorporated by reference.

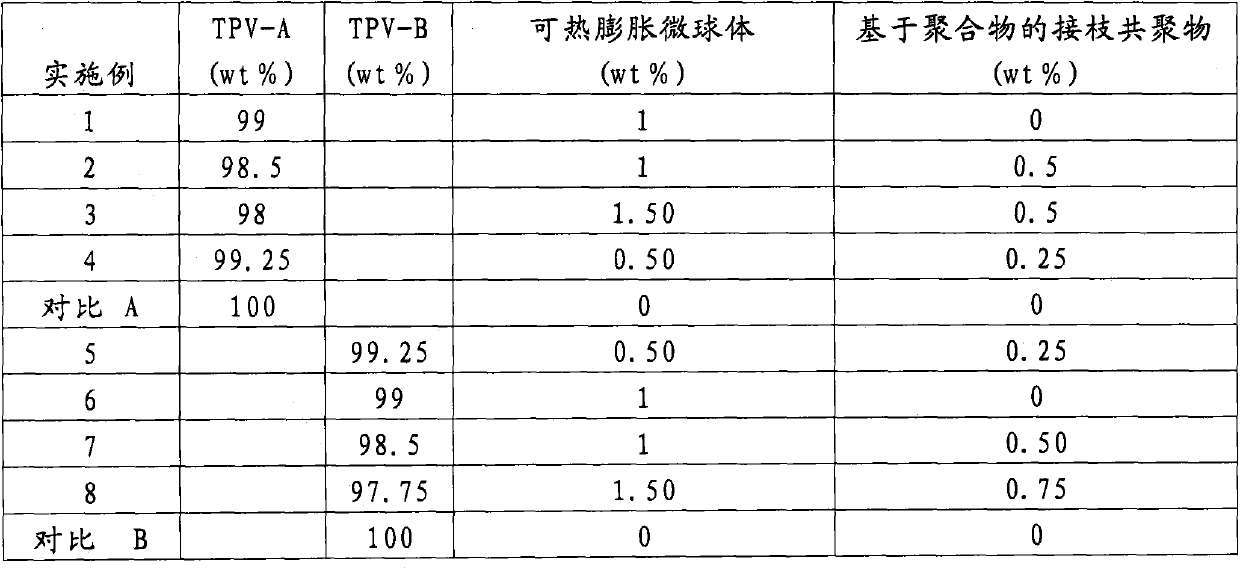

[0049] The thermally expandable microspheres may be present in the composition according to the invention in an amount ranging from 0.1% to about 10% by weight, based on the total weight of the composition. Generally, if the amount of heat-expandable microspheres is less than 0.1 wt%, the foaming effect and foam properties may be adversely affected. On the other hand, generally if the amount of thermally expandable microspheres is greater than 10% by weight, the mechanical properties of the foam may be impaired. In some embodiments of the present invention, the thermally expandable microspheres contained in the composition are preferably a...

Embodiment

[0115] Illustrative embodiments will now be described by way of example in order to demonstrate some of the advantages of the invention, but other advantages of the invention should be apparent to those skilled in the art.

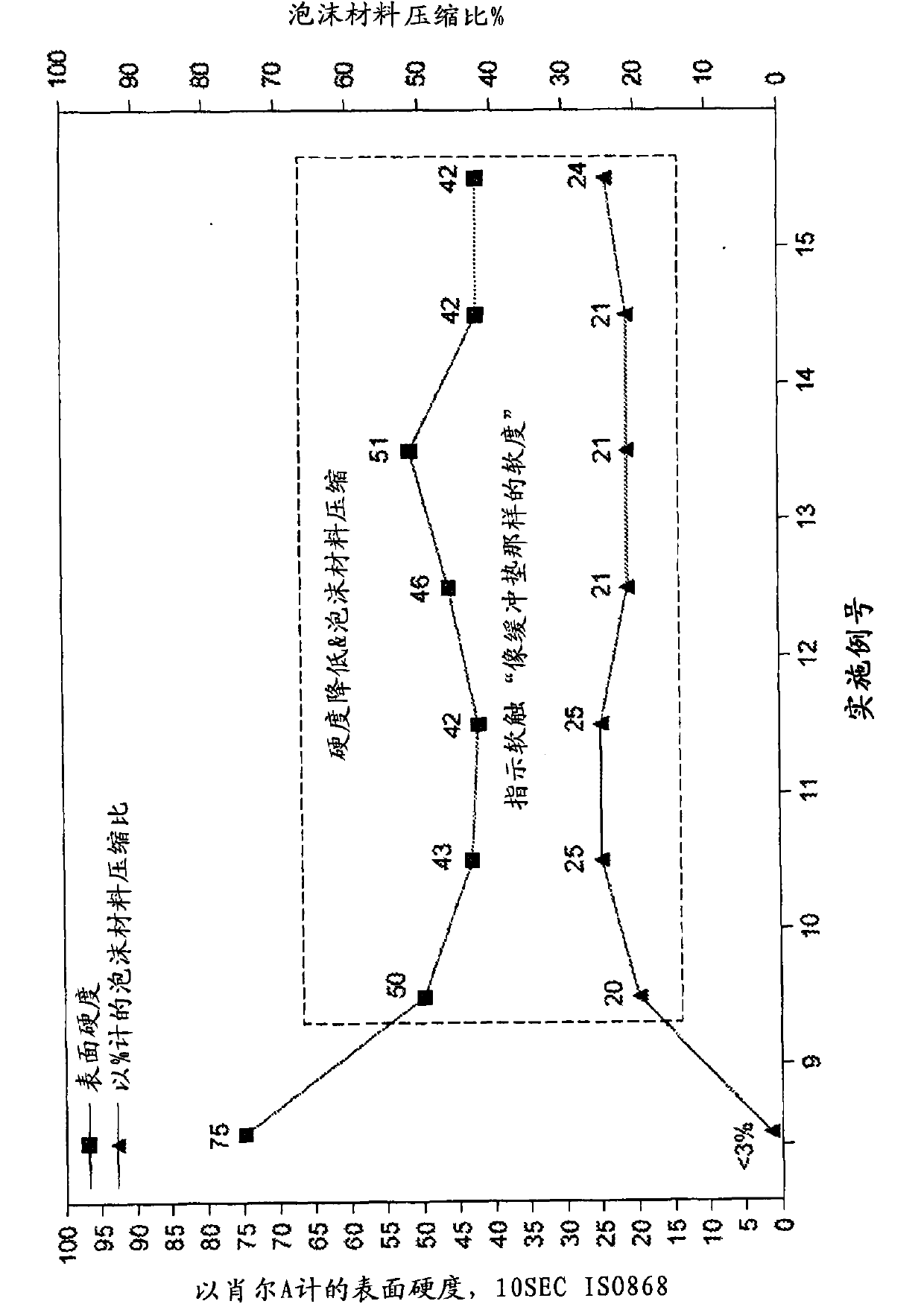

[0116] Various specific test procedures for determining properties such as density, elongation at break, tensile strength, Trouser Tear, compression ratio, Shore A hardness are given in Table 1 for convenience. However, when a person of ordinary skill reads this patent and wishes to determine whether a composition or polymer has a specific property given in a claim, any published or widely recognized method or test procedure may be followed to determine the property, but in particular The procedures given are preferred. Each claim should be construed to cover the results of any of these procedures, even to the extent that different procedures may yield different results or measurements. In general, all numerical values can be considered to be "about" or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com