Additive-free instant selenium enrichment coarse grain flour as well as preparation method thereof

An additive-free, miscellaneous grain powder technology, applied in food preparation, application, food science and other directions, can solve the problems of high cost, complex ingredients, complex process, etc., and achieve the effect of improving immunity, delicate taste, easy to disperse and dissolve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

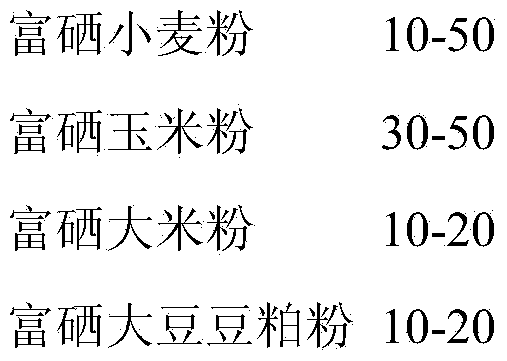

[0020] (1) Evenly mix raw materials: selenium-enriched wheat flour (selenium content 5-150 μg / g (dry weight)), selenium-enriched corn flour (selenium content 5-25 μg / g (dry weight)), selenium-enriched rice flour ( Selenium content 0.05-0.3 micrograms / gram (dry weight)), selenium-enriched soybean meal powder (selenium content 5-30 micrograms / gram (dry weight)) according to the following weight ratio, uniformly mixed:

[0021]

[0022] (2) Aging: add 1-2% water to the uniformly mixed raw materials, and use a twin-screw extruder to form aged granules at an extrusion aging temperature of 100-120°C;

[0023] (3) Grinding: Grinding the cooked granules to obtain 20-30 mesh miscellaneous grain powder;

[0024] (4) Quantitative packaging: Quantitative packaging (10g / pack) of the product obtained in (3) according to the selenium content, so as to obtain a certain selenium content, instant, non-added selenium-enriched miscellaneous grain powder product (selenium content 40-335 µg / pac...

Embodiment 2

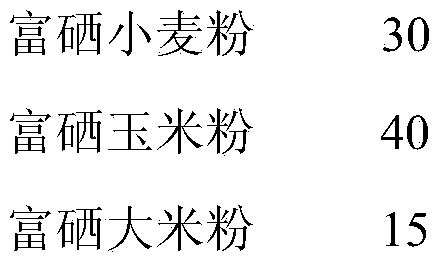

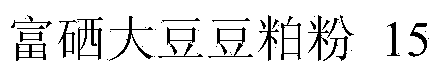

[0026] (1) Evenly mix raw materials: selenium-enriched wheat flour (selenium content 5-150 μg / g (dry weight)), selenium-enriched corn flour (selenium content 5-25 μg / g (dry weight)), selenium-enriched rice flour ( Selenium content 0.05-0.3 micrograms / gram (dry weight)), selenium-enriched soybean meal powder (selenium content 5-30 micrograms / gram (dry weight)) according to the following weight ratio, uniformly mixed:

[0027]

[0028] (2) Aging: add 1-2% water to the uniformly mixed raw materials, and use a twin-screw extruder to form aged granules at an extrusion aging temperature of 100-120°C;

[0029] (3) Grinding: Grinding the cooked granules to obtain 20-30 mesh miscellaneous grain powder;

[0030] (4) Quantitative packaging: Quantitative packaging (10g / pack) of the product obtained in (3) according to the selenium content, so as to obtain a certain selenium content, instant, non-added selenium-enriched miscellaneous grain powder product (selenium content 45-855 µg / pac...

Embodiment 3

[0032] (1) Evenly mix raw materials: selenium-enriched wheat flour (selenium content 5-150 μg / g (dry weight)), selenium-enriched corn flour (selenium content 5-25 μg / g (dry weight)), selenium-enriched rice flour ( Selenium content 0.05-0.3 micrograms / gram (dry weight)), selenium-enriched soybean meal powder (selenium content 5-30 micrograms / gram (dry weight)) according to the following weight ratio, uniformly mixed:

[0033]

[0034] (2) Aging: add 1-2% water to the uniformly mixed raw materials, and use a twin-screw extruder to form aged granules at an extrusion aging temperature of 100-120°C;

[0035] (3) Grinding: Grinding the cooked granules to obtain 20-30 mesh miscellaneous grain powder;

[0036] (4) Quantitative packaging: Quantitative packaging (10g / pack) of the product obtained in (3) according to the selenium content, so as to obtain a certain selenium content, instant, non-added selenium-enriched miscellaneous grain powder product (selenium content 43-595 µg / pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com