Kitchen cleaning and disinfecting machine with sound-light and ozone combined and working method thereof

A technology of cleaning and disinfection, ozone water, applied in the direction of kitchen utensils, applications, household utensils, etc., can solve the problems of high residual pesticides and low cleaning efficiency, and achieve the effect of good drug residue removal and remarkable cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

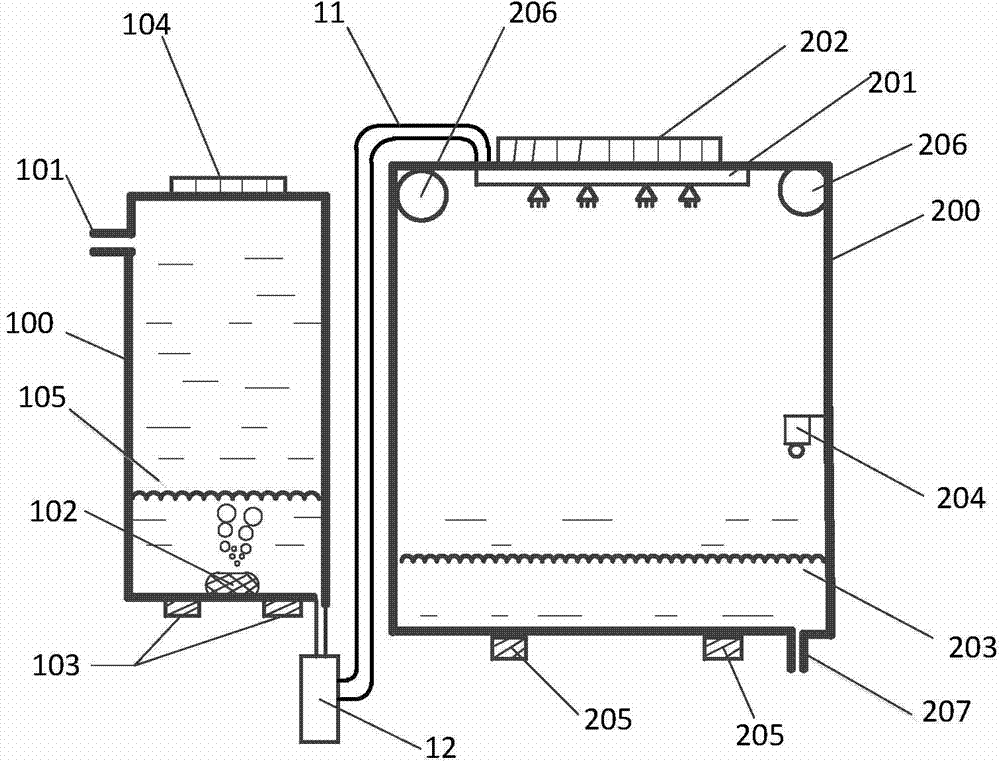

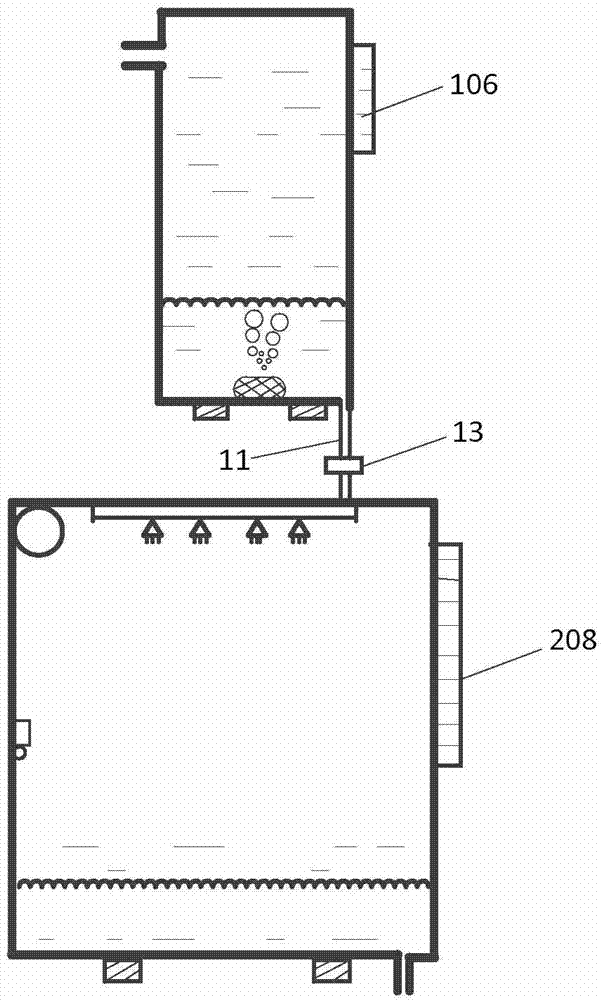

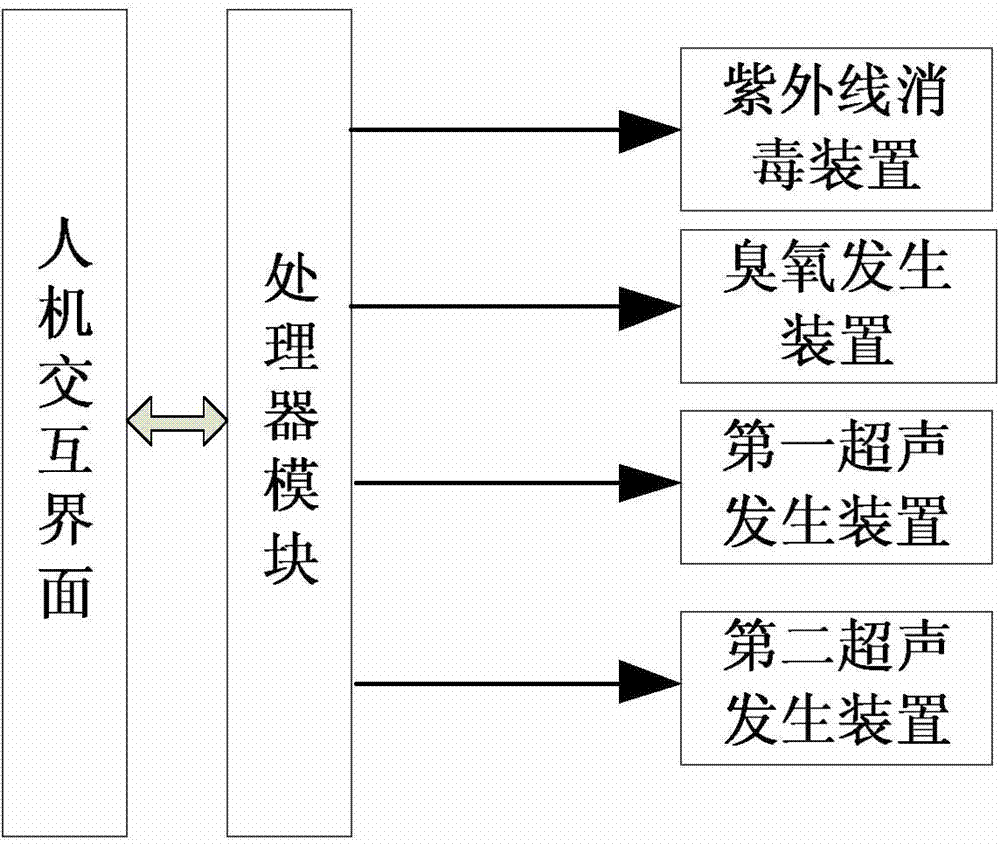

[0021] Such as figure 1 and image 3 As shown, the kitchen washer-disinfector consists of two parts, a first container 100 and a second container 200 , which are connected by a water pipe 11 . The first container 100 can be used alone to wash dishes. First, water is injected into the first container 100 through the water inlet 101, then the processor module controls the ozone generating device and the first ultrasonic generating device, and the ozone is passed into the water by the aeration head 102 in the ozone generating device. The first transducer 103 in the first ultrasonic generating device emits 40 kHz ultrasonic waves. Ozone is fully dissolved in water under the action of 40 kHz ultrasonic waves to obtain high-concentration ozone water. The tableware can be placed on the first stainless steel net 105 by opening the top cover 104 of the first container 100, and it is cleaned and disinfected under the synergistic effect of 40 kHz ultrasonic and ozone. Wherein, the ae...

Embodiment 2

[0030] The working method of the washer-disinfector based on the first embodiment above includes:

[0031] Step 1, the first container 100 generates 40kHZ ultrasonic waves and ozone through the first ultrasonic generating device and ozone generating device to generate ozone water, and the ozone water is used to clean the tableware put into the first container 100 or provide to said second container 200;

[0032] Step 2, if the ozone water is provided to the second container 200, then the second container 200 will clean the fruits and vegetables put into the second container 200 through the ozone water and the second ultrasonic generating device to generate 200kHZ ultrasonic waves, and at the same time The ultraviolet ray is generated by the ultraviolet sterilizer to sterilize the fruits and vegetables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com