High-performance double-silver-layer low-radiation glass and preparation method thereof

A low-emissivity glass, high-performance technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of weakening the light transmission of glass and reducing the visible light transmittance of low-emission glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

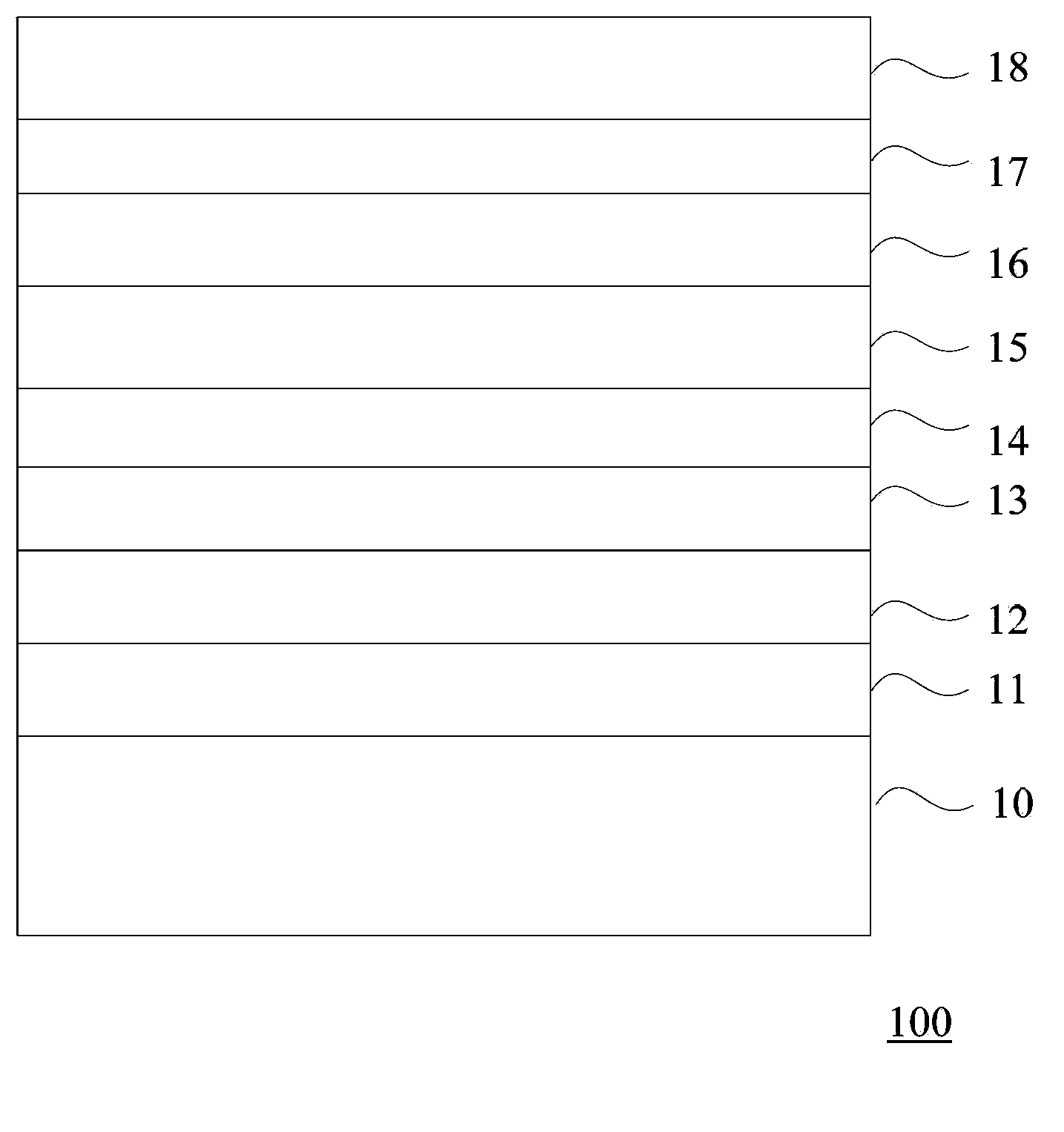

[0035] A high-performance double-silver low-emissivity glass, the film structure from the glass substrate to the outside is: glass substrate / ITO / Ag / NiCr / ITO / Ag / NiCr / ITO / ZrO 2 . Among them, the thickness of the first low surface resistance transparent conductive layer (ITO) is 30nm; the thickness of the first silver layer (Ag) is 12nm; the thickness of the first protective layer (NiCr) is 1.5nm; the second low surface resistance transparent conductive layer The thickness of the first layer (ITO) is 60nm; the thickness of the second silver layer (Ag) is 14nm; the thickness of the second protective layer (NiCr) is 2nm; the thickness of the third low surface resistance transparent conductive layer (ITO) is 40nm; Protective layer (ZrO 2 ) with a thickness of 20nm.

[0036] The steps for preparing the above-mentioned high-performance double-silver low-emissivity glass are as follows:

[0037] (1) Provide a glass substrate, clean it, dry it, and place it in a vacuum sputtering are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com