Glass lining paper and glass plate package body

A glass lining paper and glass plate technology, applied in glass production, packaging, papermaking, etc., can solve the problems of glass plate paper pattern, burn marks, contamination of the glass plate surface, etc., so as to improve the yield and inhibit disconnection or short circuit. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

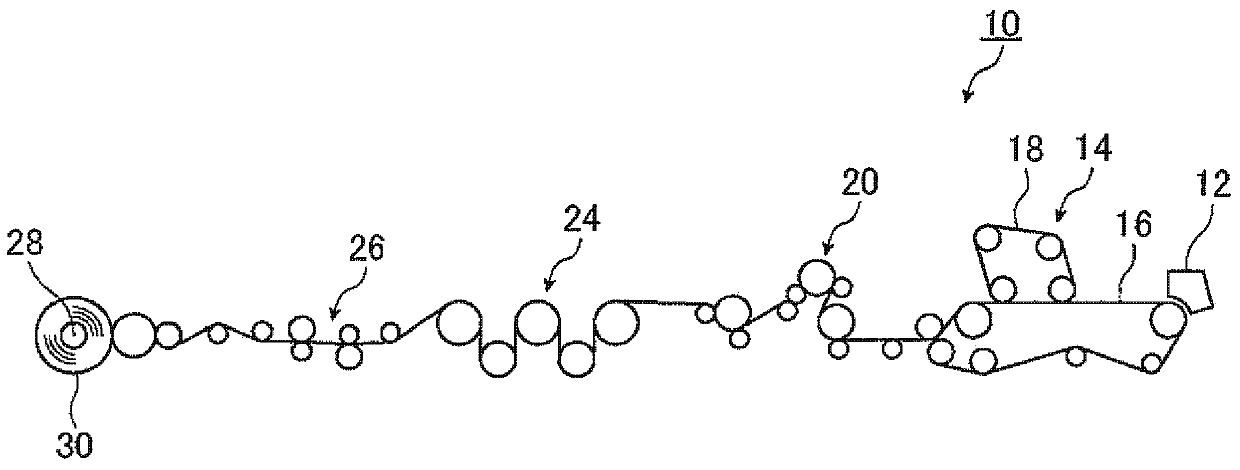

[0143] figure 1 and figure 2 In the general manufacturing apparatus for glass paper shown in , two showers for washing paper are installed in the middle of the drying section 24 .

[0144] With such a manufacturing apparatus, the raw pulp is used as a raw material, and the paper is rinsed with pure water in the drying section 24 and dried to manufacture glass paper. In addition, in this example, the calendering process in the calendering part 26 was not performed.

[0145] The prepared glass paper is cut into slices according to the size of the glass plate described later, and the glass paper is analyzed by using known methods of ICP (Inductively Coupled Plasma) mass spectrometry and ICP emission spectrometry content of metal elements.

[0146] As a result, the content of the metal element in the glass paper was 0.08% by mass.

Embodiment 2

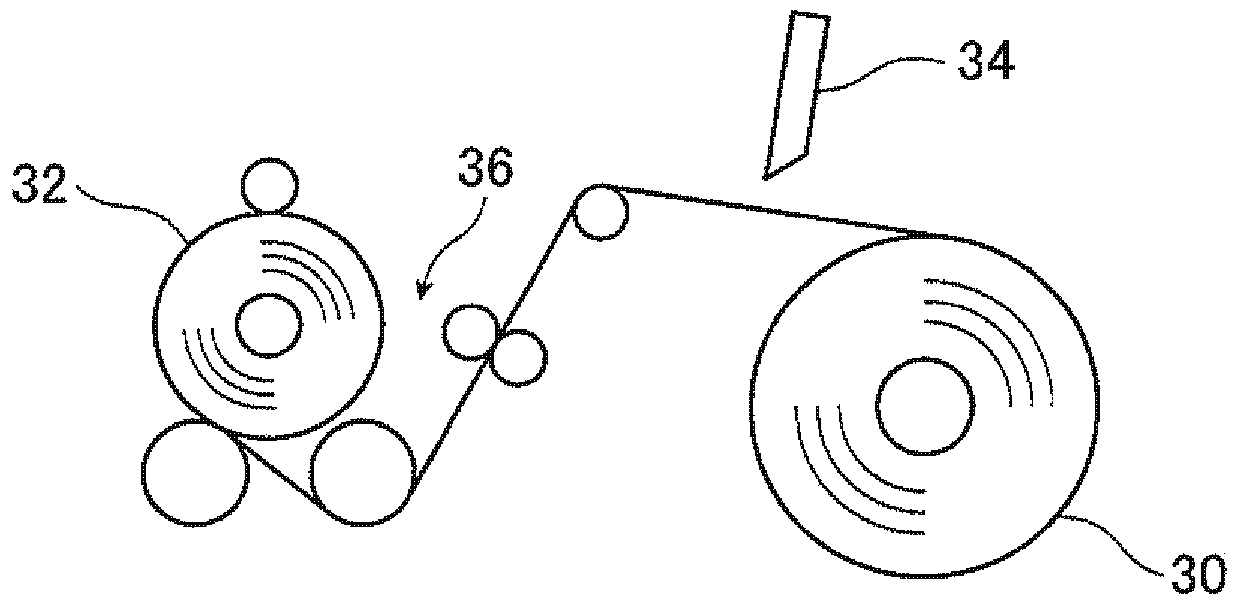

[0151] figure 1 and figure 2 In the general glass paper manufacturing apparatus shown in , an ultrasonic irradiation device and a suction device are provided between the cutter 34 and the paper roll 32 .

[0152] With such a production apparatus, the glass paper is manufactured using raw pulp as a raw material, while irradiating the glass paper with ultrasonic waves between the cutter 34 and the winder 36 and suctioning near the position where the ultrasonic waves are irradiated. In addition, in this example, the calendering process in the calendering part 26 was not performed.

[0153] The same analysis as in Example 1 was performed on the prepared glass paper, and the content of the metal element was 0.09% by mass.

Embodiment 3

[0158] use figure 1 and figure 2The manufacturing apparatus of the shown normal glass paper manufactured the glass paper using virgin pulp as a raw material.

[0159] In addition, in this example, the condition of the calendering process in the calendering part 26 was 100 kg / cm.

[0160] The prepared glass paper was cut into slices according to the size of the glass plate described later, and the air permeability of the glass paper was measured in accordance with "JIS P8117:2009", and it was 15 seconds.

[0161] As a reference, this glass paper was analyzed in the same manner as in Example 1, and the content of the metal element was 0.15% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com