Multidirectional conveying guider for flaky materials

A sheet and guide technology, applied in the field of guides, can solve the problems of high cost, cumbersome work process, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

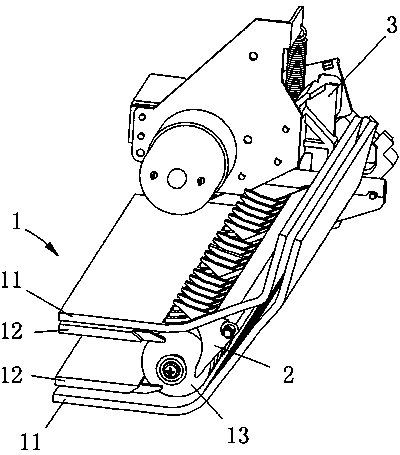

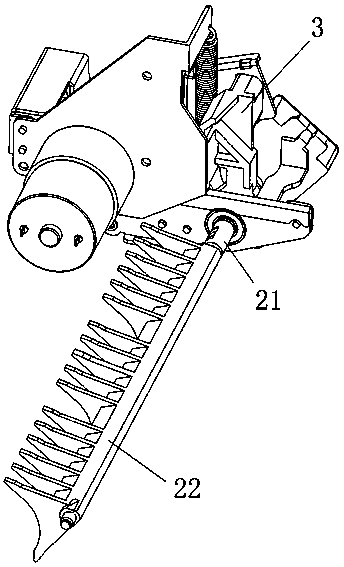

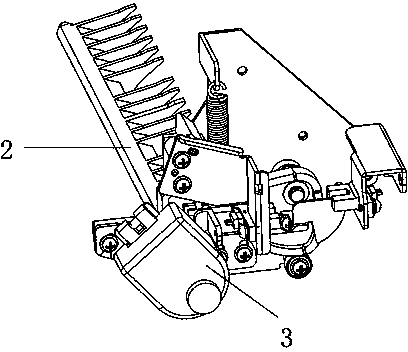

[0016] A multi-directional conveying guide for sheets, such as Figure 1-8 As shown, it includes a channel plate assembly 1 forming a multi-directional channel, a reversing vane assembly 2 that closes or opens different channels on the channel plate assembly 1, and a power drive assembly 3 that drives the reversing vane assembly 2 to move; the reversing vane assembly 2 includes a reversing vane shaft 21 that rotates around its own axis, and a reversing vane 22 that is mounted on the reversing vane shaft 21 and can close or open different passages on the channel plate assembly 1, and one end of the reversing vane shaft 21 is fixed on On the equipment frame, the other end is connected with the two-way electromagnet 36 of the power drive assembly 3; the power drive assembly 3 includes a fixed fixed bracket 31, a rotating bracket 32 that is rotatably connected to the fixed bracket 31, and the fixed bracket is equipped with a power motor 33, cam 34 is housed on the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com