Method for harmless degradation of PCP (pentachlorophenol) by using ECH (epoxy chloropropane)-SBR (styrene-butadiene rubber) combined process

A technology of ECH-SBR and combined process is applied in the field of harmless degradation of pentachlorophenol (PCP) to achieve the effect of high catalytic activity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) in Pd 2+ (15mM), Cu 2+ (5mM), in the pH1.0 electrolyte, the titanium mesh is the cathode, the platinum sheet is the anode, and the constant potential is -0.9V (relative to Hg / Hg 2 SO 4 electrode) deposited for 25min to obtain a Pd-Cu / Ti electrode. The potential scanning range is -800mV~700mV, the scanning speed is 50mV / s, and the CV scans the Pd-Cu / Ti electrode 50 times to obtain a CV50Pd-Cu / Ti electrode.

[0024] 2) Add 30mL10mg / L PCP and Na to the cathode chamber of the electrolytic cell in the bipolar chamber 2 SO 4 , where Na 2 SO 4 Concentration 0.05M, add 30mL0.05M Na to the anode chamber 2 SO 4 , 0.1M sulfuric acid to adjust the pH of the cathode chamber to 2.3. The electrode prepared in step (1) was placed in the cathode chamber of the reactor, and the platinum sheet was used as the counter electrode to be placed in the anode chamber. Dechlorination was performed at 5 mA for 90 minutes. cathodic reactant solution.

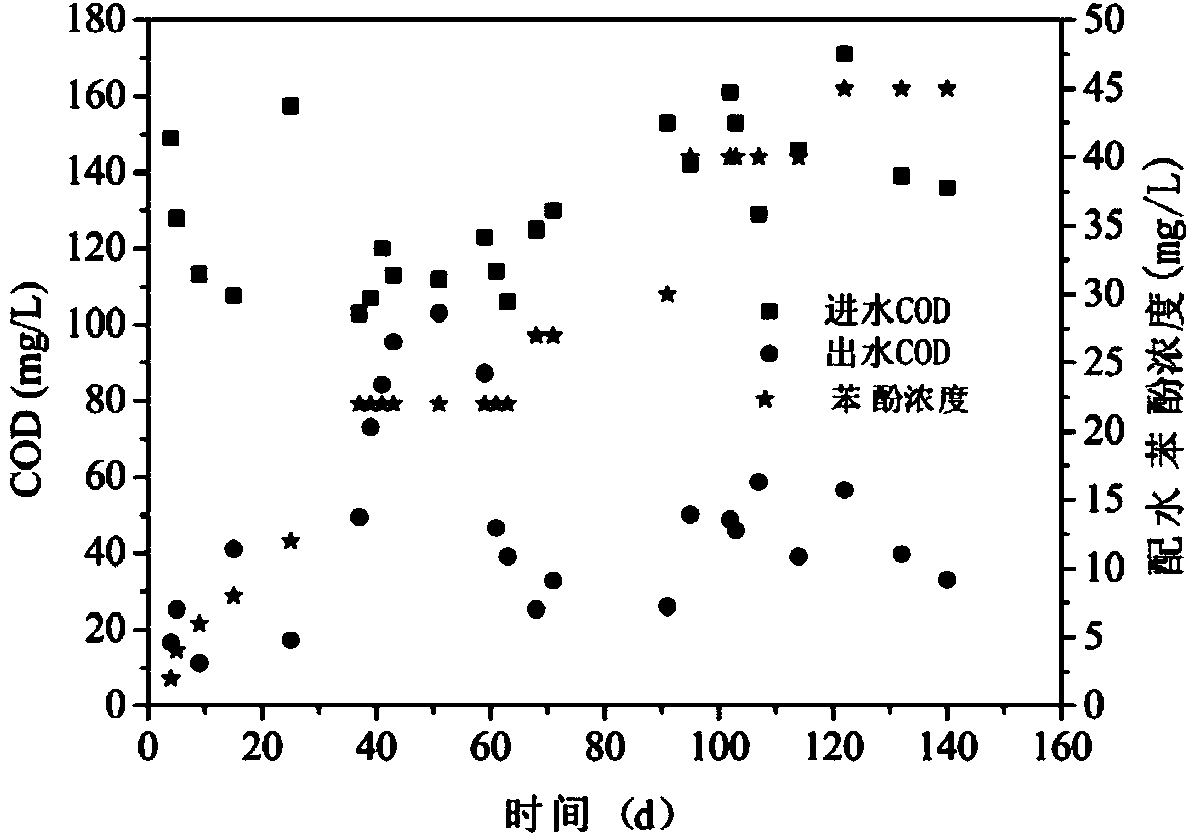

[0025] 3) From 1 to 95 days, in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com