Method for producing seedling substrate by rapid fermentation of papermaking sludge

A technology for papermaking sludge and seedling substrate, which is applied in the application, preparation of organic fertilizers, treatment of biological organic parts, etc., can solve the problems of ecological environment destruction, non-compliance with sustainable development strategies, etc., and achieves strong resistance and simple production method. The effect of controllable and comprehensive economic cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

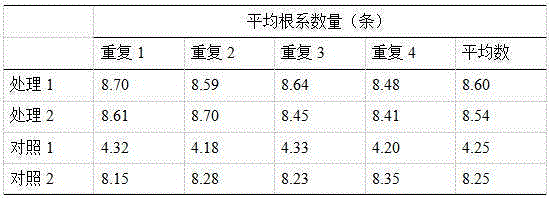

Embodiment 1

[0037] (1) According to the volume ratio of papermaking sludge: mushroom slag: sawdust = 3:6:1, a total of 100m is weighed 3 Crush the raw material to 30mm, and slowly pour water for 2 to 3 days to make the moisture content reach 60% (the judgment standard is to hold a handful of substrate firmly, and it is better if water overflows between fingers and does not flow out). Add 50kg of urea, mix evenly, pile into a pile with a width of 2.0m and a height of 1.5m, and ferment;

[0038] (2) Turn the pile for the first time after the fermentation temperature of the pile rises to 60°C and last for 48 hours; when the temperature of the pile rises to 55°C again, turn the pile for the second time so that the temperature of the pile drops below 40°C, and then continue Aging on the ground without hard bottom for 20 days to complete the compost fermentation;

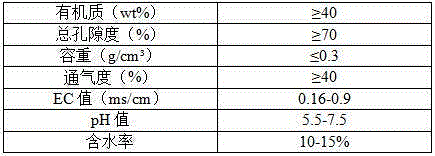

[0039] (3) Spread the fermented compost in the air to keep the moisture content below 12%, and then mix it with perlite and peat s...

Embodiment 2

[0042] (1) According to the volume ratio of papermaking sludge: mushroom slag: sawdust = 2:7:1, a total of 100m is weighed 3 Crush the raw material to 50mm, slowly pour water for 2 days to make the moisture content reach 50% (judgment standard is to hold a handful of substrate firmly, and it is advisable that water overflows between fingers and does not flow out). Add 30kg of urea, mix evenly, pile into a pile with a width of 3.0m and a height of 2.0m, and ferment;

[0043] (2) After the fermentation temperature of the heap rises to 55°C and lasts for 72 hours, the first turning is carried out; when the temperature of the heap rises to 50°C again, the second turning is made to reduce the temperature of the heap to below 40°C, and then continue Aging on the ground without hard bottom for 15 days to complete the compost fermentation;

[0044](3) Spread the fermented compost in the air to make the moisture content lower than 12%, and then mix it with perlite and peat soil at a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com