Organosilicon material OCA as well as preparation method and application thereof

An organosilicon and polysiloxane technology, used in adhesive additives, bonding methods, non-polymer adhesive additives, etc., can solve problems such as affecting the sensitivity of contacts, achieve good prospects for industrialization and promotion, and achieve light transmission. High efficiency, simple and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] OCA of silicone material, consisting of the following raw materials: (meth)acrylate-terminated polysiloxane 62g, MQ silicone resin 24g, γ-(methacryloyloxy)propyltrimethoxysilane 11g, 2-methoxysilane 2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone 2g, 1,2-diphenylbenzofuran 1g.

[0025] Configure according to the following method: first add (meth)acrylate-terminated polysiloxane, MQ silicone resin, γ-(methacryloyloxy)propyltrimethoxysilane in a planetary vacuum mixer, heat to 40- Stir at -60°C for 20-30min, then add 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-acetone, 1,2-diphenyl Base benzofuran, stirred in vacuum for 20min, and the whole process of stirring should be protected from light. After stirring, the mixture was filtered in the dark, and finally packaged through sealed tubes.

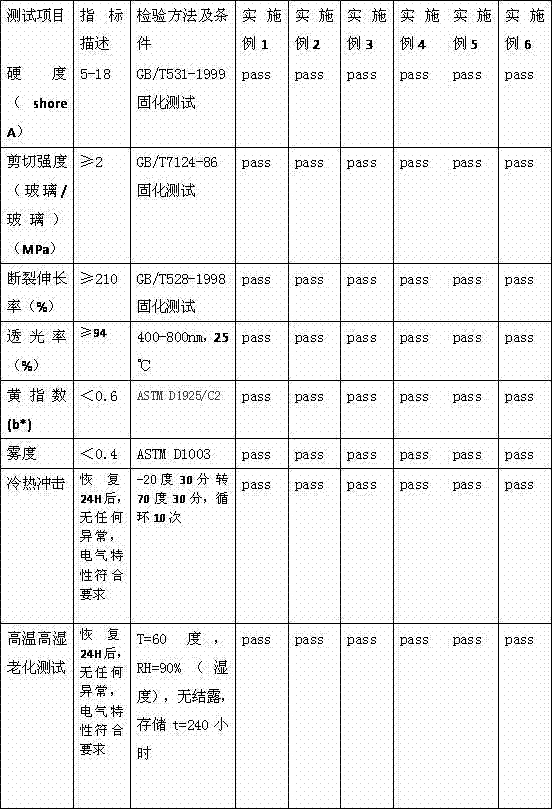

[0026] The formulated silicone material has excellent OCA test performance, as shown in Table 1.

Embodiment 2

[0028] OCA of silicone material, consisting of the following raw materials: (meth)acrylate-terminated polysiloxane 50g, MQ silicone resin 26g, γ-(methacryloyloxy)propyltrimethoxysilane 21g, 2-methoxysilane Base-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone 1g, 2-hydroxy-2-phenylacetophenone 1g, 1,2-diphenyl 1 g of benzofuran.

[0029] Configure according to the following method: first add (meth)acrylate-terminated polysiloxane, MQ silicone resin, γ-(methacryloyloxy)propyltrimethoxysilane in a planetary vacuum mixer, heat to 40- Stir at -60°C for 20-30min, then add 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl]-1-propanone, 2-hydroxy-2- Phenylacetophenone and 1,2-diphenylbenzofuran were stirred in vacuum for 20 minutes, and the whole process of stirring should be protected from light. After stirring, the mixture was filtered in the dark, and finally packaged through sealed tubes.

[0030] The formulated silicone material has excellent OCA test performance, as s...

Embodiment 3

[0032] OCA of silicone material, consisting of the following raw materials: (meth)acrylate-terminated polysiloxane 54g, MQ silicone resin 20g, γ-(methacryloyloxy)propyltrimethoxysilane 22g, 2-hydroxy -2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone 3g, 1,2-diphenylbenzofuran 1g.

[0033] Configure according to the following method: first add (meth)acrylate-terminated polysiloxane, MQ silicone resin, γ-(methacryloyloxy)propyltrimethoxysilane to a planetary vacuum mixer, heat to 40- Stir at -60°C for 20-30min, then add 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, 1,2-diphenylbenzo Furan, stirred in vacuum for 20min, and the whole process of stirring should be protected from light. After stirring, the mixture was filtered in the dark, and finally packaged through sealed tubes.

[0034] The formulated silicone material has excellent OCA test performance, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com