Electron beam zone melting furnace and method for carrying out float zone purification on material

An area purification and electron beam technology, applied in the direction of self-area melting method, chemical instruments and methods, polycrystalline material growth, etc., to achieve the effect of providing work comfort, wide application range and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

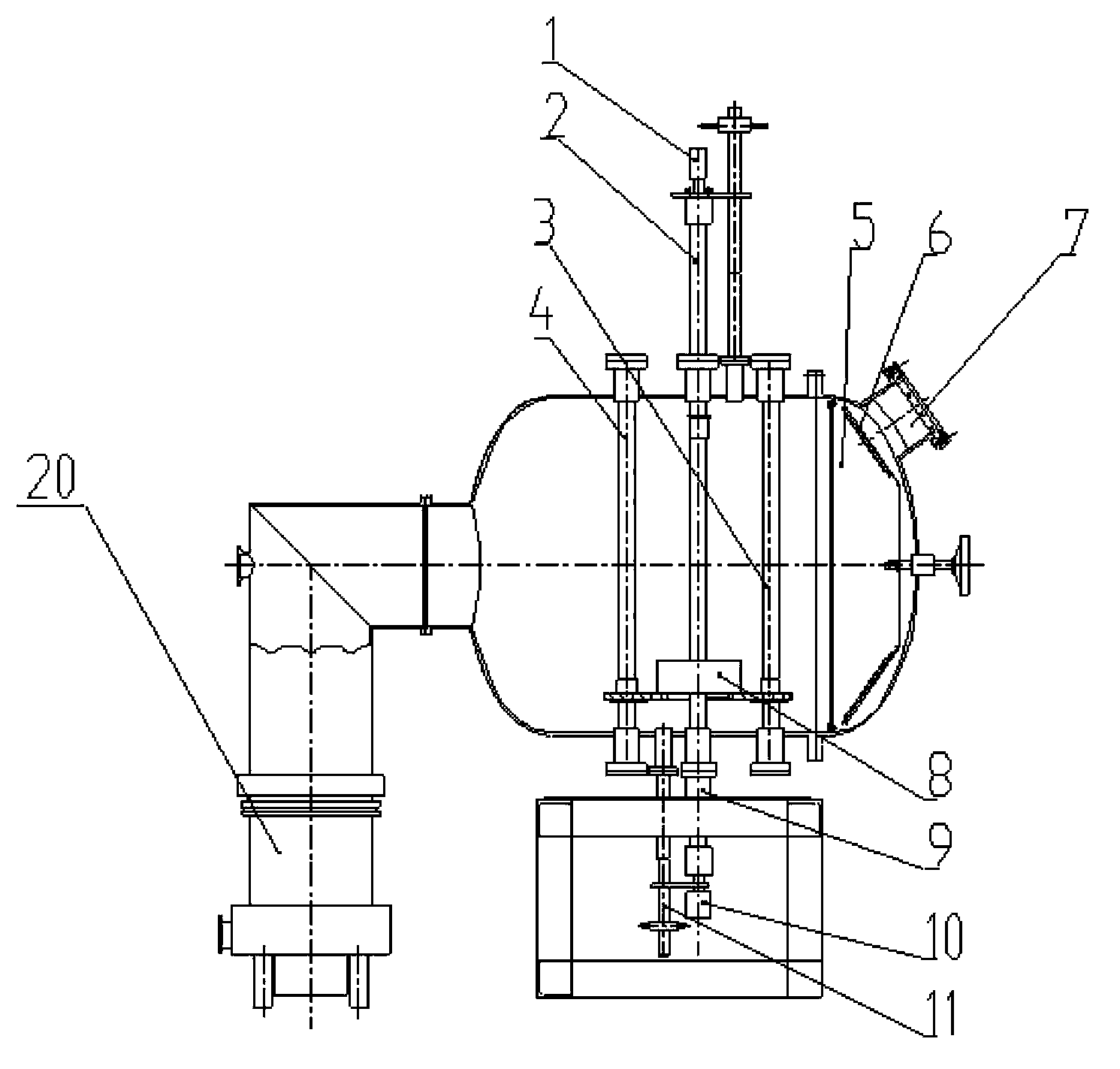

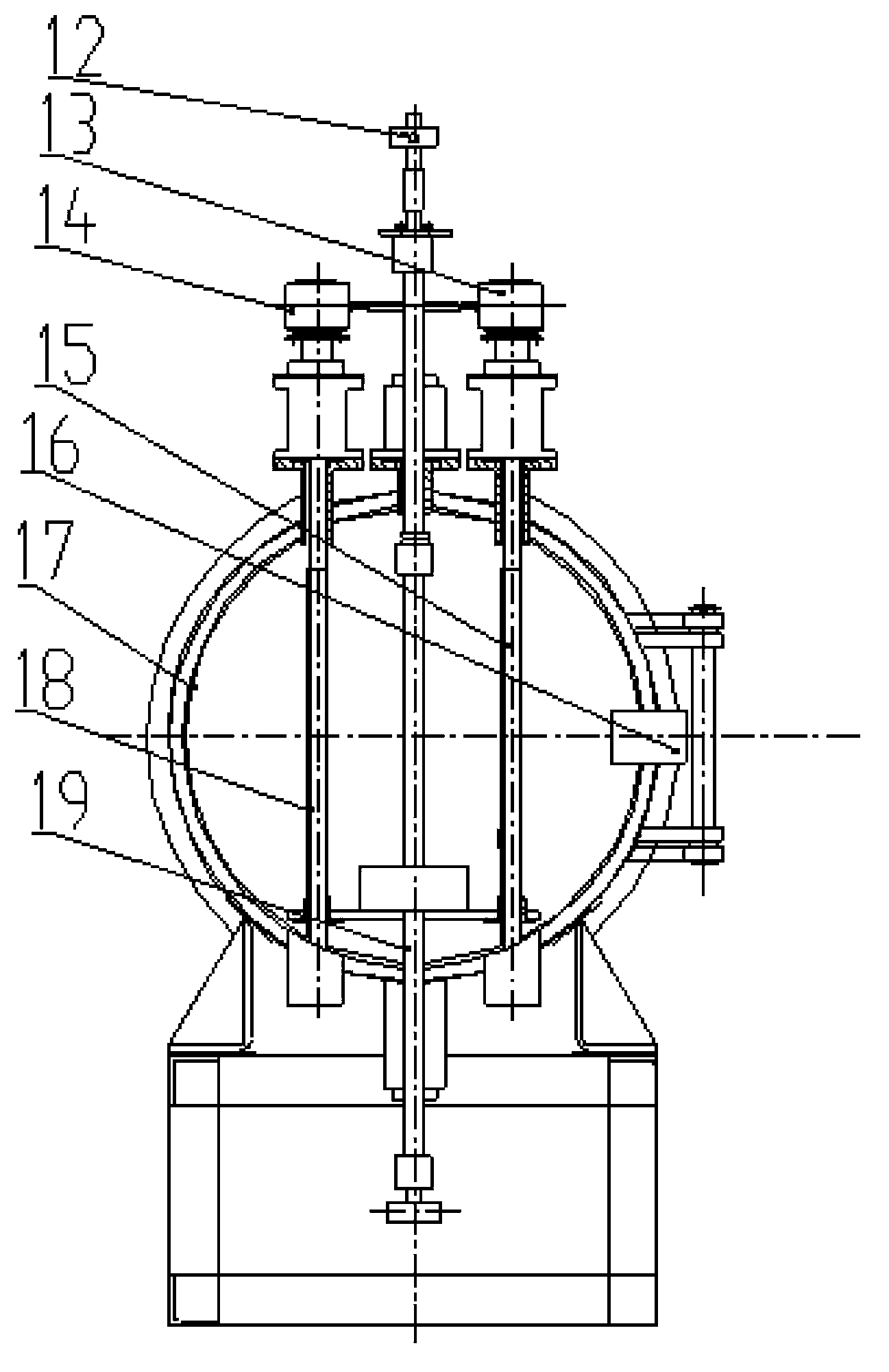

[0031] The main composition of the electron beam zone melting furnace for refining materials in the suspension zone of the present invention is composed of a furnace body, an electron gun and a solid material device, and is equipped with a refrigeration system, a vacuum unit and a rocker mechanism for a control panel. The materials mentioned are generally rod-shaped high-temperature refractory samples.

[0032] Such as figure 1 As shown, the present invention can be designed with a workbench, and the furnace body is placed on the workbench.

[0033] The body of furnace is built-in an annular electron gun 8, which is sleeved on the outer ring of the material 19 during smelting. The electron gun 8 can be an electron gun body using existing power structures. In the present invention, a device that can drive An electron gun lifting system that moves the electron gun up and down. The electron gun lifting system can be composed of at least two lead screws driven by servo motors and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com