A atomized molecular accelerator device for car carbon removal fluid

A technology of acceleration device and decarbonization liquid, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve the problems of inability to work for a long time, inability to meet the operation of decarbonization of automobile engines, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

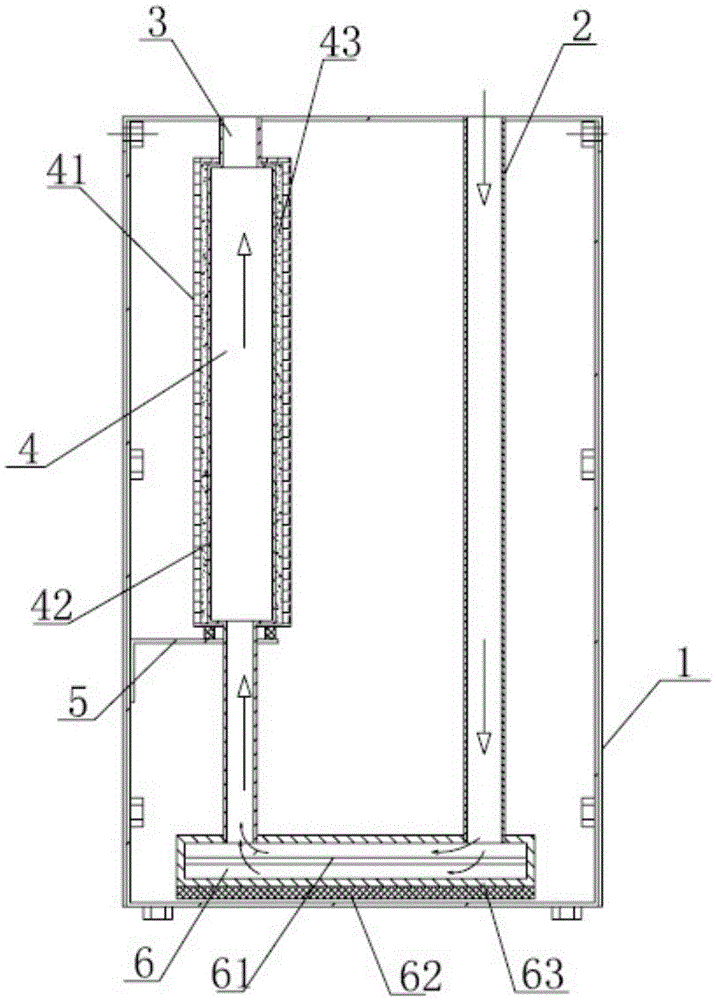

[0028] Connect the upper end of the intake pipe 2 with the atomization device, and the outlet pipe 3 communicates with the intake valve of the engine, and then energize the PTC heating sheet. When the PTC heating sheet is energized, the impact current makes the temperature rise rapidly, and the PTC heats up. The resistance value of the chip immediately enters the high-resistance transition zone, and only the residual current keeps the surface temperature of the PTC heating chip at a constant value.

[0029] The temperature of the PTC heating plate is transmitted to the titanium alloy generating plate 61 through the metal shell 63, so that the temperature of the titanium alloy generating plate 61 rises to 150° C. in a short time.

[0030] Then the atomized mist carbon removal liquid enters the metal shell 63 through the intake pipe 2, and after being fully contacted and heated with the titanium alloy generating plate 61, the temperature rises to 130 ° C ~ 140 ° C, which improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com