Particle catalyst conveying pipeline connector

A technology of particle catalyst and conveying pipeline, applied in the direction of non-removable pipe connection, pipe/pipe joint/pipe fitting, passing element, etc., which can solve the problems of smooth, difficult and long top distance of weld joint processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

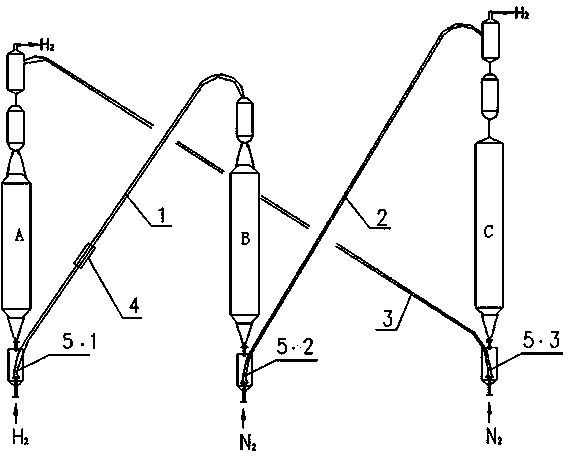

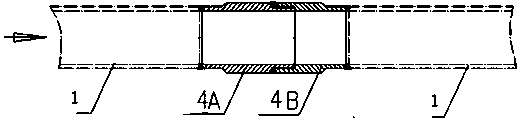

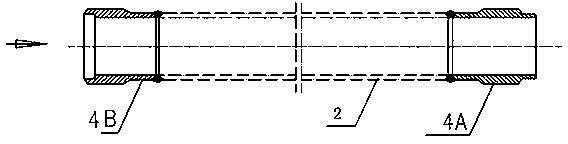

[0020] Such as figure 2 , 3 As shown, a connector for a pipeline for conveying particulate catalysts is located at the connection end of the catalyst conveying pipeline, including: a connector assembly 4A, a connector assembly 4B, and the connector assembly 4A and the connector assembly 4B are male and female structures; The inner diameter of the middle pipe of the connector assembly 4A of the male structure matches the inner diameter of the catalyst delivery pipe, and the outer diameter of the middle pipe of 4A is greater than the outer diameter of the catalyst delivery pipe; the pipe sections at both ends of the connector assembly 4A match the inner diameter of the catalyst delivery pipe. It is consistent with the outer diameter, and the pipe section at one end of the connector assembly 4A is smoothly and fixedly connected with the catalyst delivery pipe, and the pipe section at the other end of the connector assembly 4A is connected with the connector assembly 4B extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com