Redundant water draining system of high-back-pressure units of origin station of heat supply network

A high back pressure, unit technology, applied in the directions of preheating, supplementary water supply, lighting and heating equipment, etc., can solve problems such as disturbance, unit water level influence, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

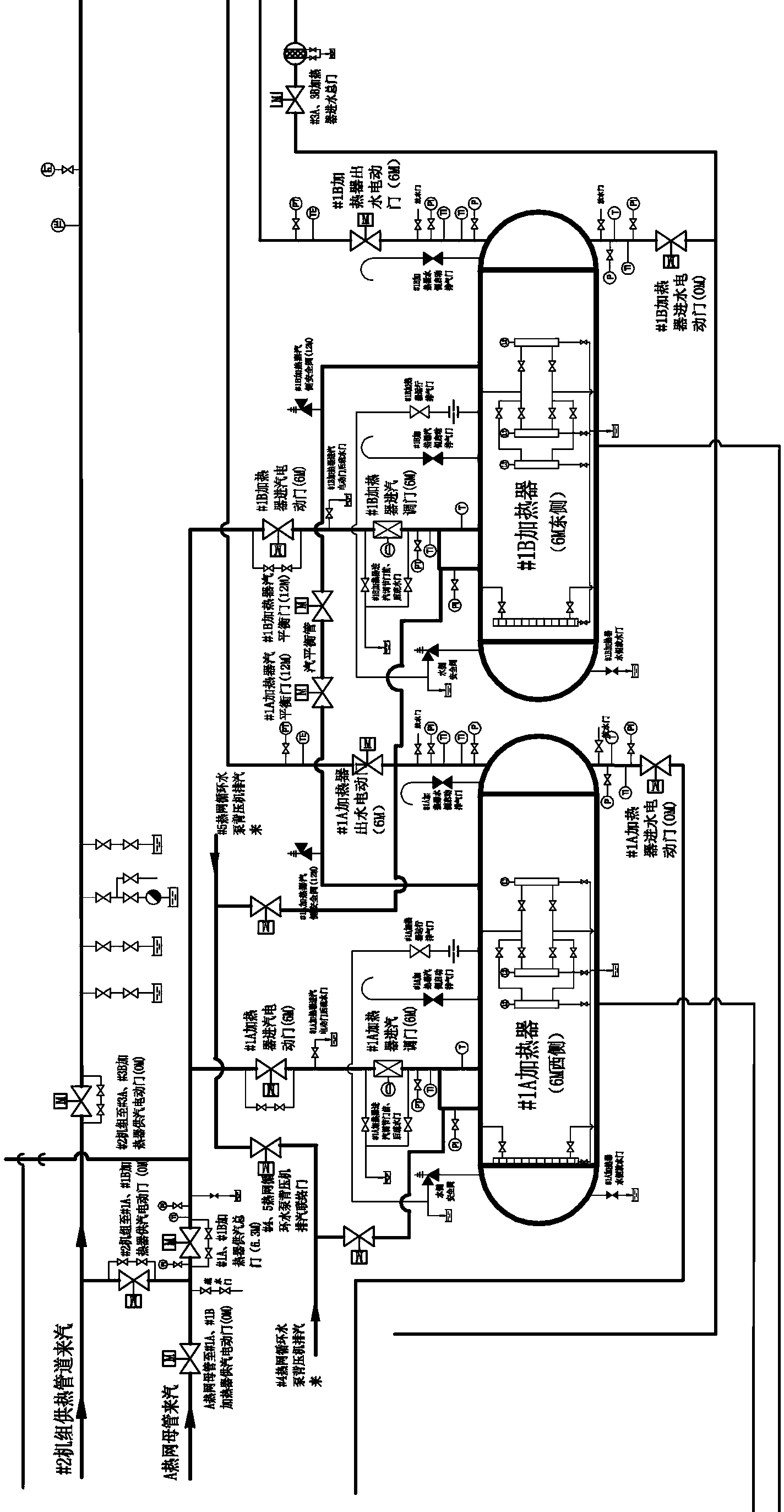

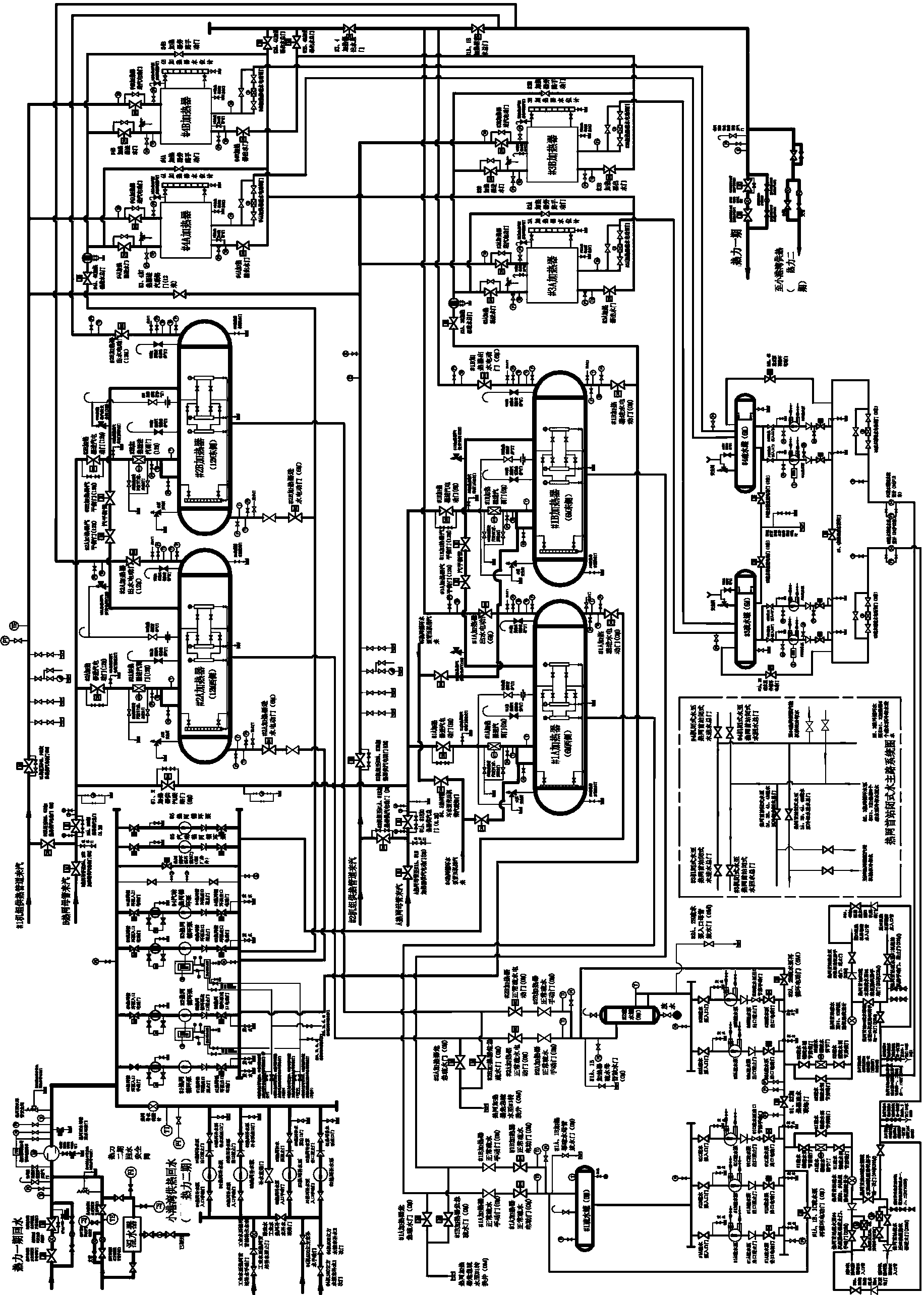

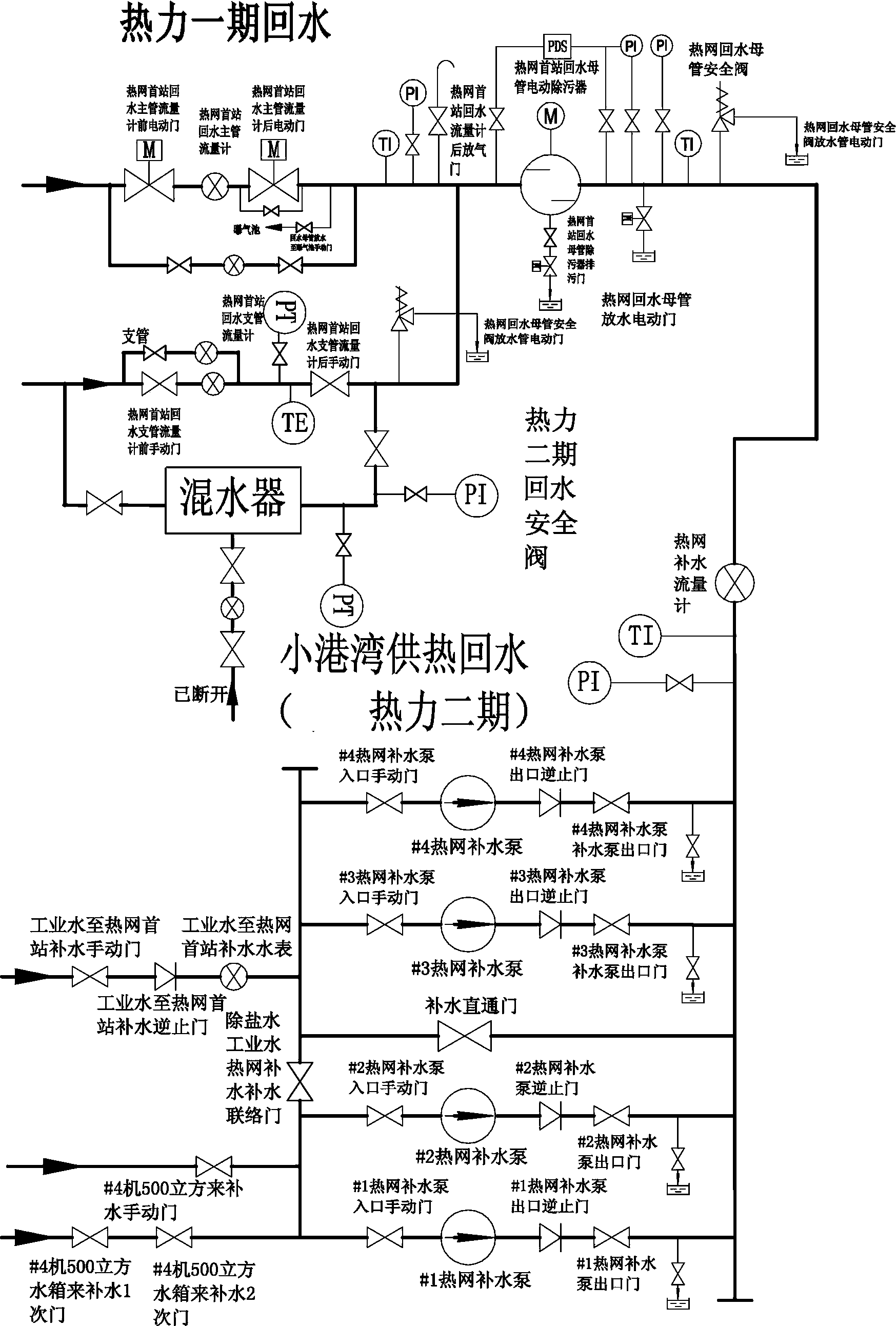

[0123] A redundant water drainage system for high back pressure units at the first station of the heating network, including unit #2 and unit #4, the sealing water of the feed pump of unit #2 and the spray water of the low pressure cylinder are all cut to the condensate water supply of the adjacent unit ; The #1A heater and #1B heater at the first station of the heating network are drained and recycled to the condensate inlet pipe of the #2 machine deaerator and the condensate inlet pipe of the #4 machine deaerator, and the return pipe is added Equipped with an electric adjustment door for drainage.

Embodiment 2

[0125] A redundant water drainage system for high back pressure units at the first station of a heating network, which is similar to Embodiment 1, except that the #2 unit is a high back pressure unit.

Embodiment 3

[0127] A redundant water drainage system for high back pressure units at the first station of the heating network, similar to Embodiment 2, the difference is that the #1A heater and #1B heater are supplied with #2 unit steam The steam is supplied from the hot pipe, and the water after heat exchange is distributed to the condensed water inlet pipe of the #4 machine deaerator through the electric control door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com