Design method of mechanical draft cooling tower of essential service water system in nuclear power plant

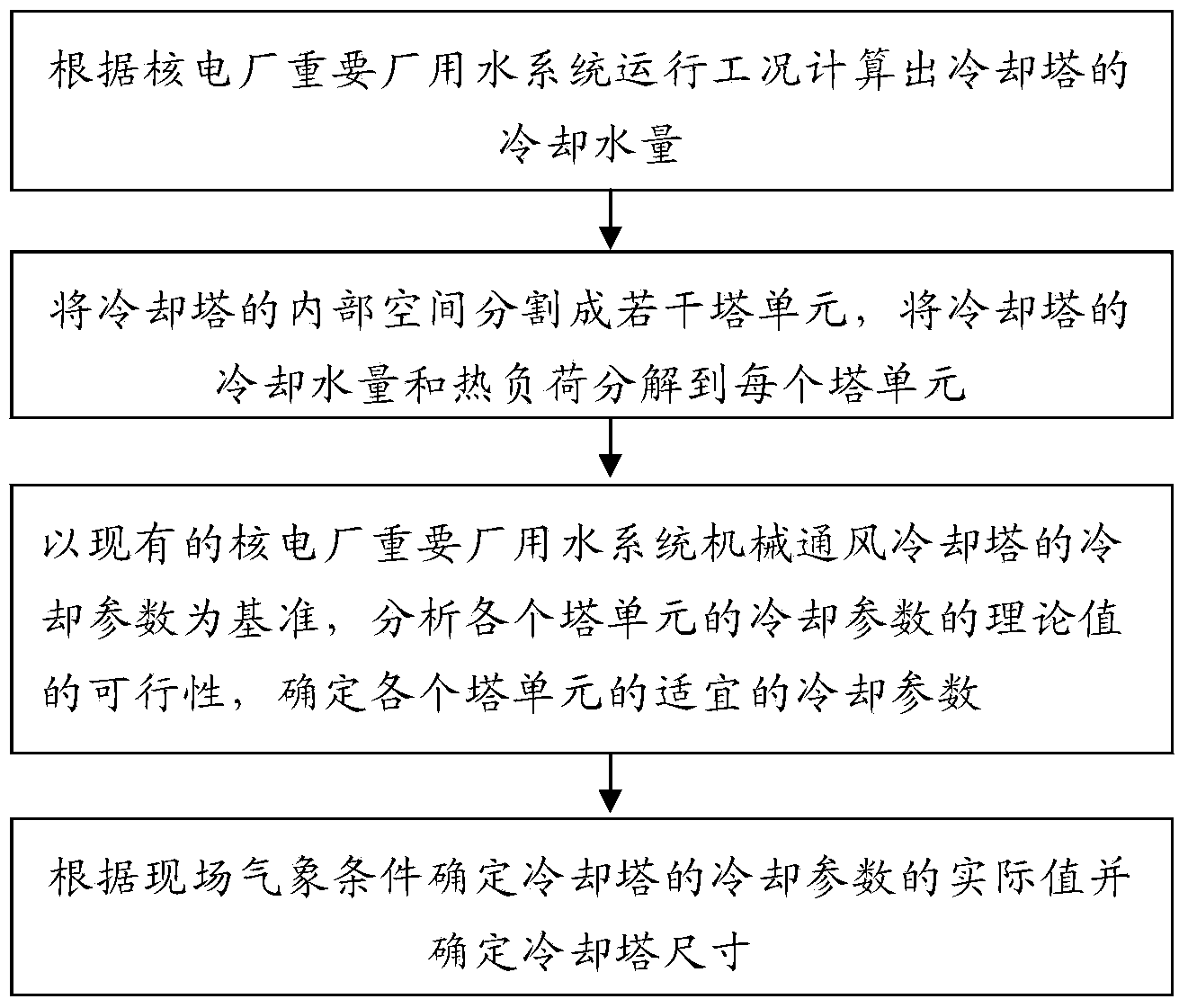

An important plant water and mechanical ventilation technology, applied in the direction of water shower coolers, refrigeration plants, lighting and heating equipment, etc., can solve the problems of complicated design of mechanical ventilation cooling towers, long design cycle, and many manpower and material resources, etc., to achieve reduction Design time and design cost, improve design efficiency, and meet the effect of construction needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

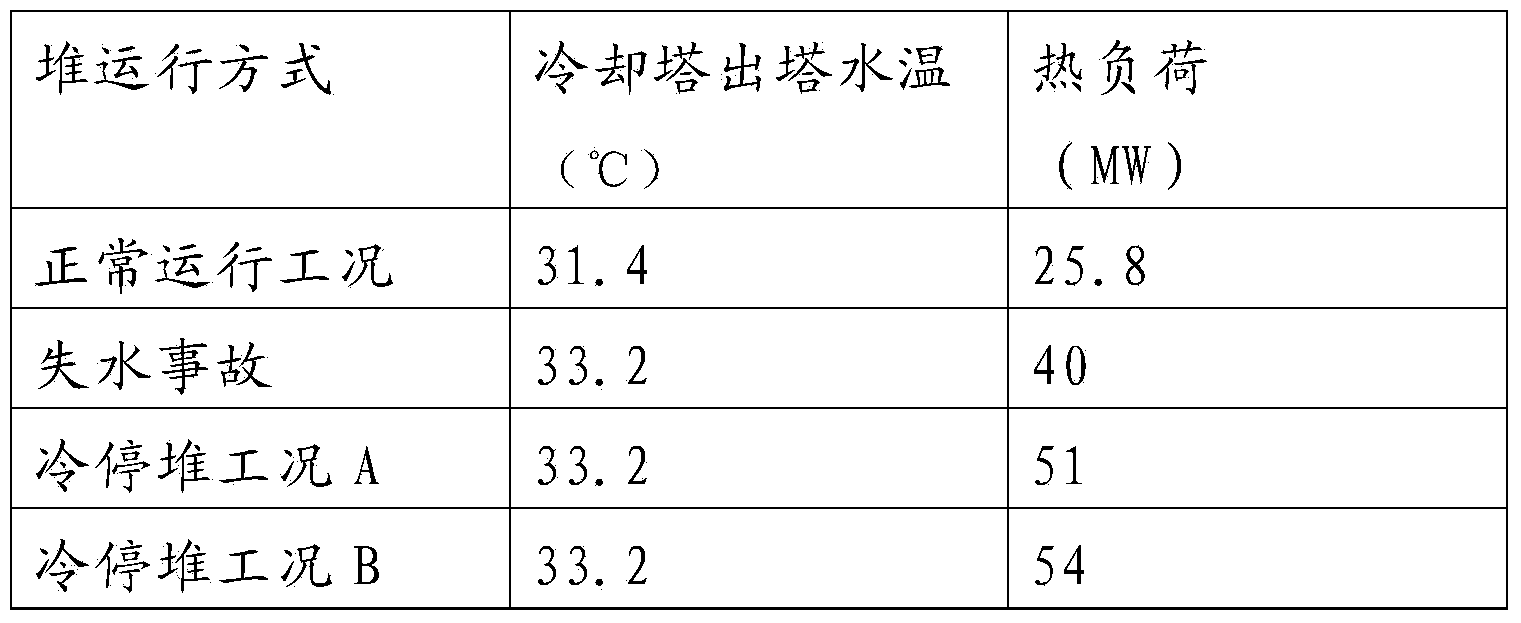

[0028] Table 1 shows the parameter values of the important plant water system of the nuclear power plant under different operating conditions, including the cooling tower outlet water temperature, heat load, etc.

[0029] Table 1

[0030]

[0031] According to the maximum temperature difference between the inlet and outlet water of the cooling tower in the important plant water system is 10°C, combined with Table 1, the main design parameters under different working conditions shown in Table 2 below are calculated:

[0032] Table 2

[0033]

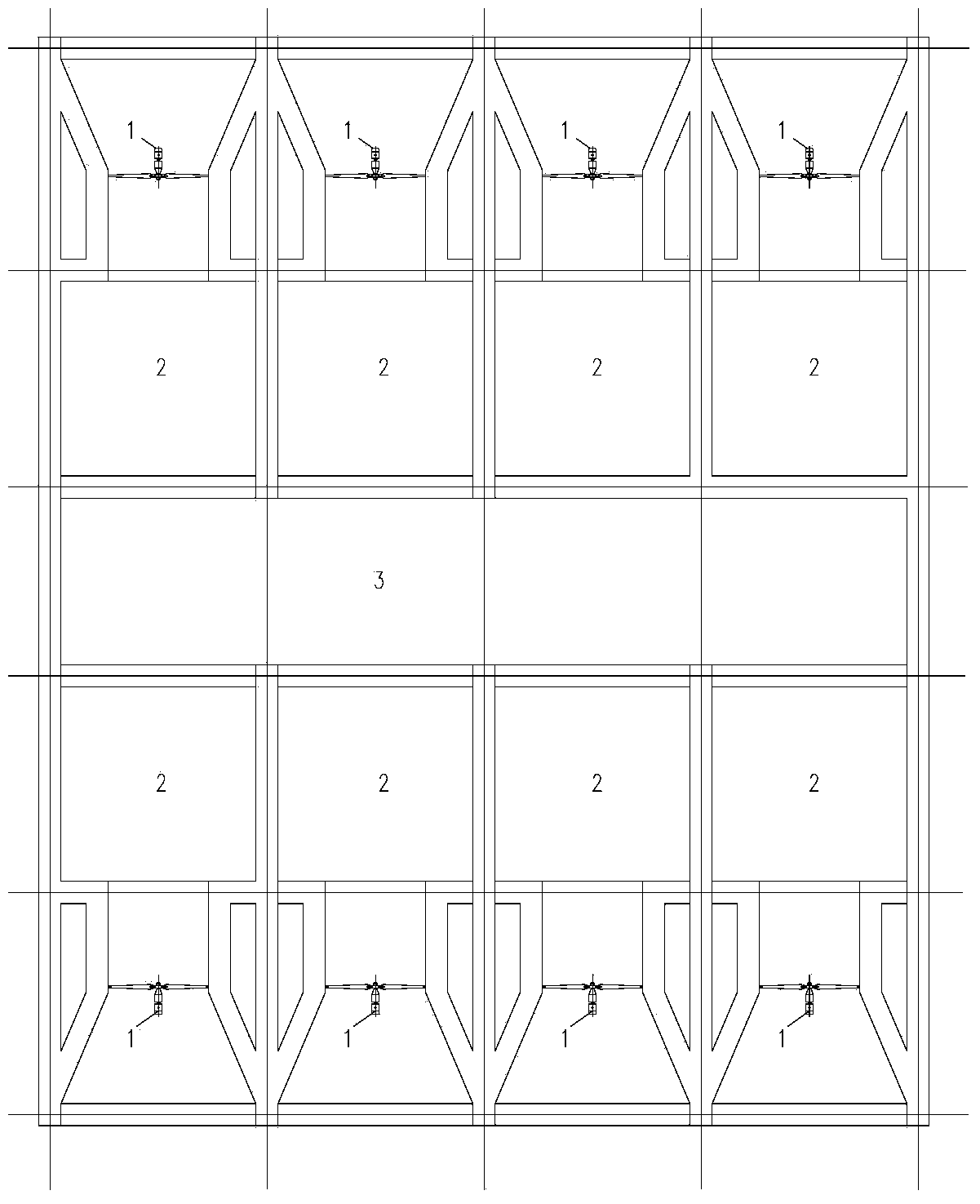

[0034] According to the above table 2, each cooling tower can be divided, and the principle is to set the number of units operating under each working condition as an even number. According to this principle, the cooling tower can be divided into 8 or 10 units, 6 or 8 units are in operation under the most unfavorable conditions, and 2 units are in standby. Under normal operating conditions, 4 units operate, each unit has a heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com