A pss patterned substrate etching method

A technology for patterning substrates and substrates, applied in the field of plasma, can solve the problems of decreased production efficiency, increased bottom width of PSS patterns, etc., and achieves the effects of suppressing bottom width, improving PSS etching process, and improving growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]In order to enable those skilled in the art to better understand the technical solution of the present invention, the method for etching a PSS patterned substrate provided by an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

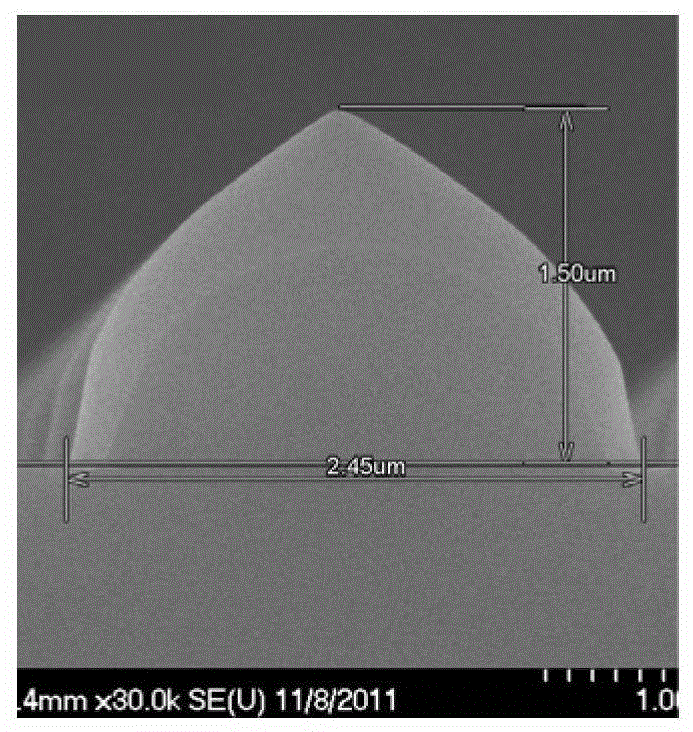

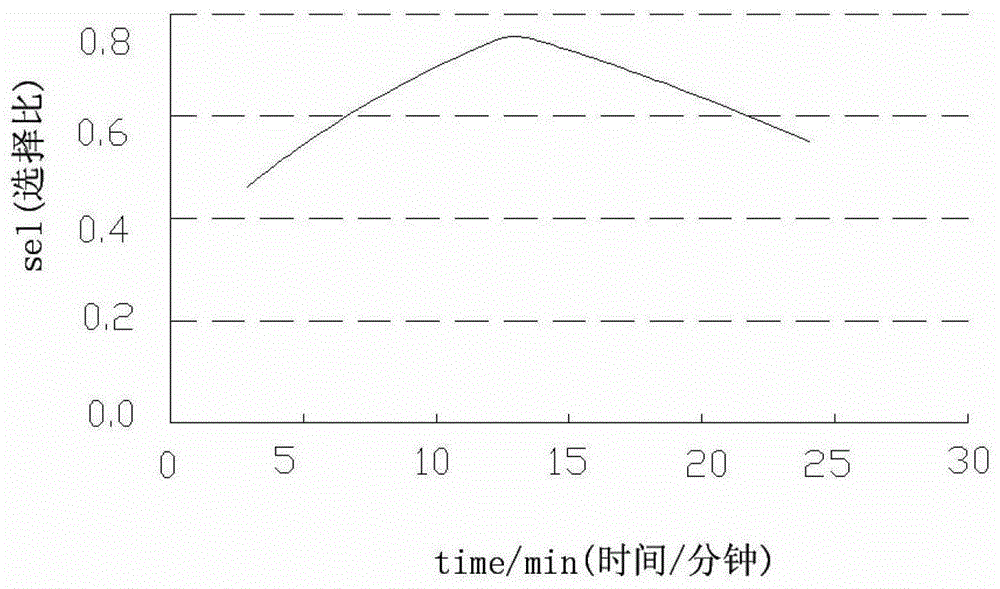

[0041] In order to suppress the widening of the bottom width of the PSS pattern in the PSS process, a set of experimental data on the change of the selection ratio and the bottom width in the etching process is provided in the embodiment of the present invention, and based on the experiment, the embodiment of the present invention proposes a A PSS patterned substrate etching method. see Figure 3A , which shows the change graph of the selectivity ratio during the main etching process, in Figure 3A Among them, the change of selectivity presents an increase first and then decrease, which is similar to a parabolic law, in which the turning point of selectivity from increase to decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com