Production method for type N ohm contact electrode of GaN based power type LED

An ohmic contact electrode, power-type technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of radio frequency damage to GaN substrates, poor thermal stability of N-GaN electrode alloy systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

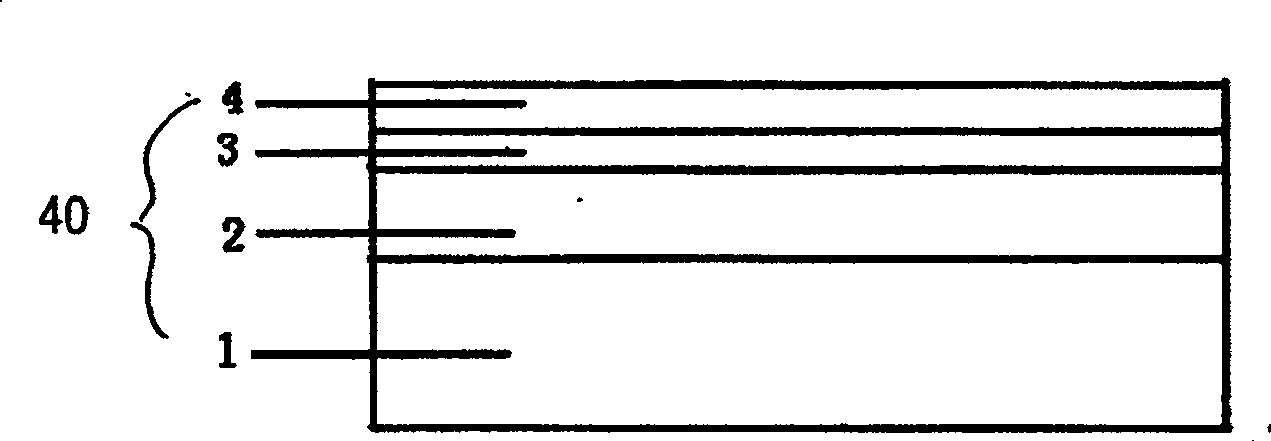

[0031] An N-type ohmic contact electrode for a GaN-based power LED and a preparation method thereof. The manufacturing process is generally to form an N-GaN layer 2, an active layer 3 and a P-GaN layer 4 on a sapphire substrate 1 by means of epitaxy , forming the material structure 40 of a GaN-based power LED, such as figure 1 shown.

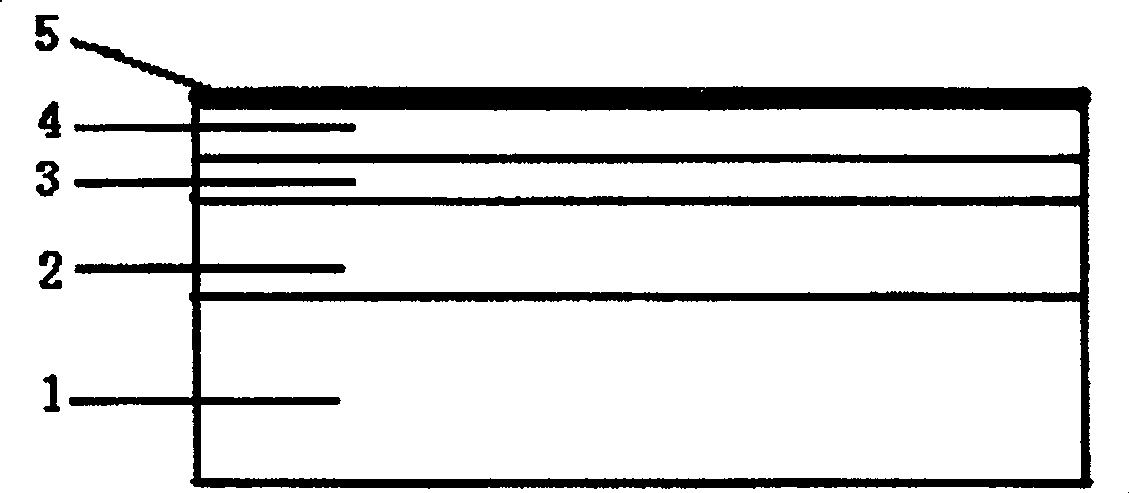

[0032] On the upper surface P-GaN layer 4 of the material structure (delete 40) of the epitaxial GaN-based power LED on the sapphire substrate 1, a layer of thickness 5000 is deposited by PECVD method. SiO 2 masking layer 5, such as figure 2 shown, where the PECVD-deposited SiO 2 Masking layer 5, evacuated to a pressure of less than 10 in the PECVD vacuum chamber -5 Pa, the temperature rises to 300°C and remains stable, the temperature is raised to 300°C in the vacuum chamber and remains stable, and the vacuum chamber is filled with N with a gas flow rate of 392 sccm 2 , 150sccm SiH 4 and 1420sccm N 2 O until the chamber pressure is 0.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com