Heaters for plasma processing plants

A processing device and heater technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting the etching rate and etching uniformity, affecting the heating effect of the heating component 102, etc., so as to reduce power loss. , avoid influence, reduce the effect of coupling current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

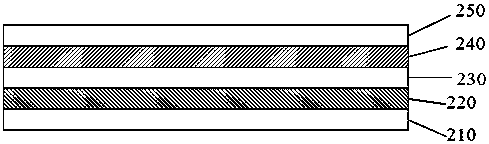

[0020] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

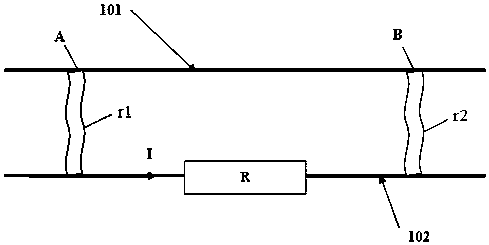

[0021] The invention discloses a heater for a plasma processing device of inductively coupled plasma (ICP).

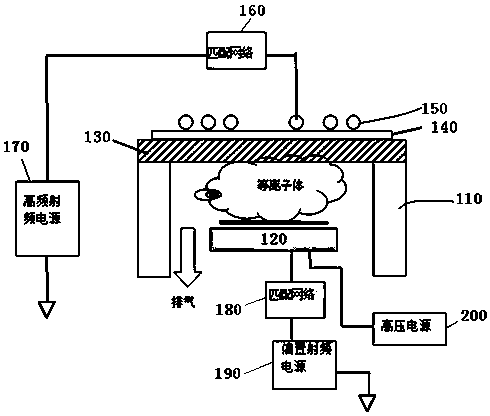

[0022] Such as figure 2 As shown, in an embodiment of an inductively coupled plasma plasma processing device, the plasma processing device includes an inductively coupled plasma reaction chamber (ICP chamber) 110, and the shape of the reaction chamber 110 is not limited to a cylindrical shape, for example It can also be horn-shaped.

[0023] At the bottom of the reaction chamber 110, there is a support table 120 for placing wafers. The support table 120 can be provided with electrostatic chucks for absorbing wafers, electrodes, temperature modulation mechanisms such as heaters or refrigerant flow paths, etc. . During semiconductor processing, the inside of the processing chamber is filled with plasma.

[0024] The top of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com