Cleaning device and method

A cleaning device and cleaning water technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of increased waste liquid treatment costs, reduced productivity, reduced safety, etc., to achieve increased The cost of waste liquid treatment, the maintenance of yield rate, and the effect of water saving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

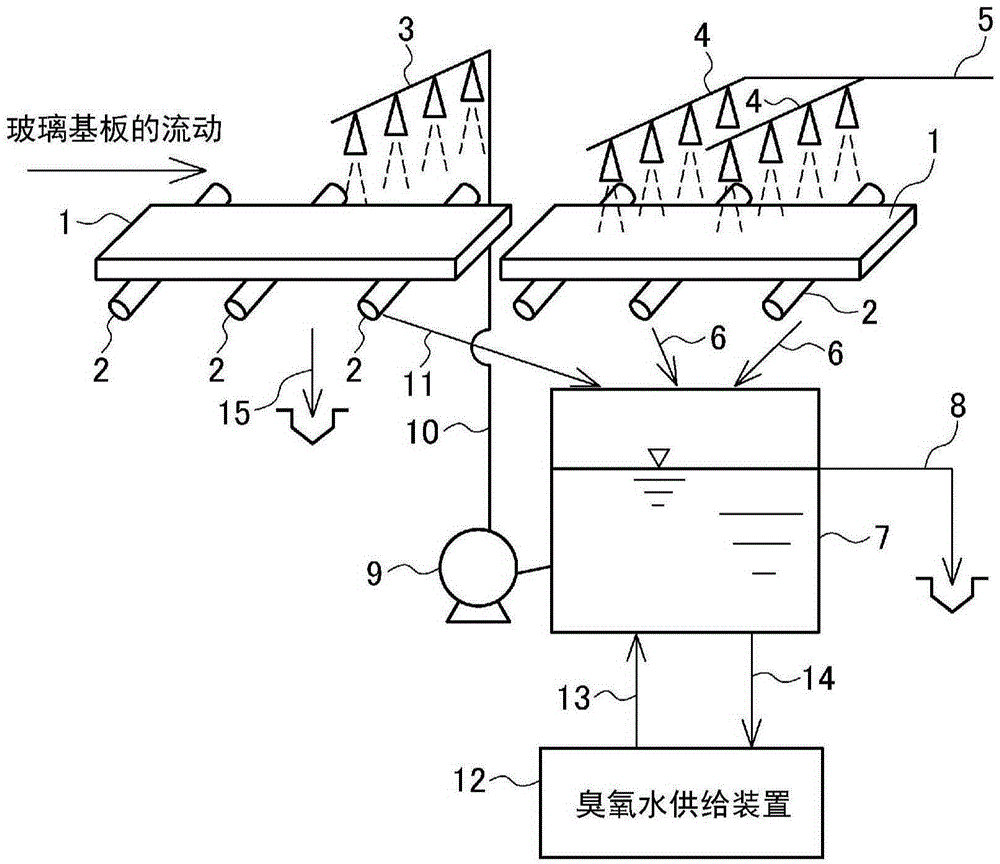

[0034] in such as figure 1 In the shown glass substrate cleaning apparatus, the cleaning conditions are as follows. In addition, the recovery of the pre-cleaning waste water by the pipe 11 is not performed.

[0035] Pure water supply from piping 5: 20L / min

[0036] Capacity of water tank 7: 400L

[0037] Water delivery rate from water tank 7 to jet cleaning nozzle 3: 100L / min

[0038] Discharge from piping 15: 20L / min

[0039] Cleaning was carried out for 10 days under these conditions, and when the number of bacteria in the water in the water tank 7 became 150 / mL and the number of bacteria in the water discharged from the jet cleaning nozzle 3 was 100 / mL, the supply of pure water was stopped and The pump 9 is stopped, and the water in the water tank 7 is circulated at the ozone water supply device 12 at a flow rate of 100 L / min by the pipes 14 and 13, and the ozone water with an ozone concentration of 1 mg / L is introduced from the pipe 13 towards the water tank 7. In 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com