Environment-friendly photoresist cleaning liquid and preparation method thereof

A technology of photoresist and cleaning solution, which is applied in the field of environment-friendly photoresist cleaning solution and its preparation, can solve the problems of increased processing cost, large environmental impact, cleaning power that does not corrode the substrate, etc., and achieves good cleaning effect, The effect of small environmental hazards and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

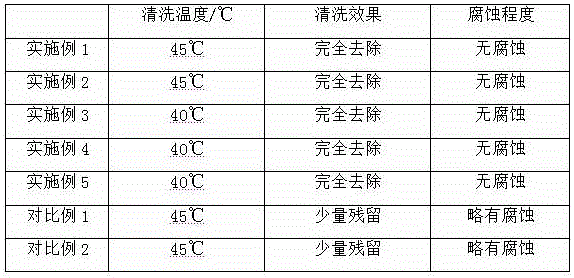

Examples

Embodiment 1

[0022] An environmentally friendly photoresist cleaning solution, comprising the following components in parts by weight: 5 parts of 5-butyl hydantoin, 2-6 parts of dimethyl fumarate, and tris(3-methoxyphenyl)phosphine 2 Parts, 4 parts tetradecyl dimethyl betaine, 3 parts polyethylene glycol oleate, 1 part tea saponin, 1 part carbon molecular sieve, 2 parts decyl glucoside, 2 parts isobutyl salicylate , 1 part of D-talitol, 2 parts of 2-(diethanolamino)ethanesulfonic acid, 3 parts of betulinic acid, 0.2 part of ionone, 1 part of diallyl dimethyl ammonium chloride, 1 part of lauroyl di 1 part of ethanolamine, 0.8 part of polyethylene glycol bisester, 2 parts of dehydroabietic acid, 5 parts of α-terpineol, and 18 parts of deionized water.

[0023] The preparation method of the environmental protection photoresist cleaning solution includes the following preparation steps:

[0024] Step 1) Add tea saponin into deionized water, stir to dissolve, and then add diallyl dimethyl ammonium ...

Embodiment 2

[0029] An environmentally friendly photoresist cleaning solution, comprising the following components by weight: 12 parts of 5-butyl hydantoin, 6 parts of dimethyl fumarate, 8 parts of tris(3-methoxyphenyl) phosphine, 10 parts of myristyl dimethyl betaine, 8 parts of polyethylene glycol oleate, 5 parts of tea saponin, 4 parts of carbon molecular sieve, 6 parts of decyl glucoside, 6 parts of isobutyl salicylate, D -4 parts of talitol, 6 parts of 2-(diethanolamino)ethanesulfonic acid, 7 parts of betulinic acid, 1 part of ionone, 3 parts of diallyldimethylammonium chloride, 4 parts of lauroyl diethanolamine Parts, 3 parts of polyethylene glycol diacid ester, 6 parts of dehydroabietic acid, 9 parts of α-terpineol, 25 parts of deionized water.

[0030] The preparation method of the environmental protection photoresist cleaning solution includes the following preparation steps:

[0031] Step 1) Add tea saponin into deionized water, stir to dissolve, then add diallyl dimethyl ammonium ch...

Embodiment 3

[0036] An environmentally friendly photoresist cleaning solution, comprising the following components in parts by weight: 7 parts of 5-butyl hydantoin, 2.5 parts of dimethyl fumarate, 3 parts of tris(3-methoxyphenyl) phosphine, 4.2 parts of tetradecyl dimethyl betaine, 3.5 parts of polyethylene glycol oleate, 1.2 parts of tea saponin, 1.5 parts of carbon molecular sieve, 2.2 parts of decyl glucoside, 3 parts of isobutyl salicylate, D -1.38 parts of talitol, 2.4 parts of 2-(diethanolamino)ethanesulfonic acid, 3.8 parts of betulinic acid, 0.4 parts of ionone, 1.2 parts of diallyldimethylammonium chloride, 1.4 parts of lauroyl diethanolamine Parts, 0.9 parts of polyethylene glycol diacid ester, 2.4 parts of dehydroabietic acid, 5.6 parts of α-terpineol, and 19 parts of deionized water.

[0037] The preparation method of the environmental protection photoresist cleaning solution includes the following preparation steps:

[0038] Step 1) Add tea saponin into deionized water, stir to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com