Method for severing a semiconductor component assemblage

A technology for semiconductor and composite parts, which is applied in the field of dividing semiconductor device composite parts and can solve problems such as damage to semiconductor chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Elements that are the same, of the same type or having the same function are provided with the same reference signs in the drawings.

[0030] The drawings and the size ratio of the elements shown in the drawings to each other cannot be regarded as to scale. More precisely, for better visibility and / or for better understanding, individual elements can be shown exaggerated.

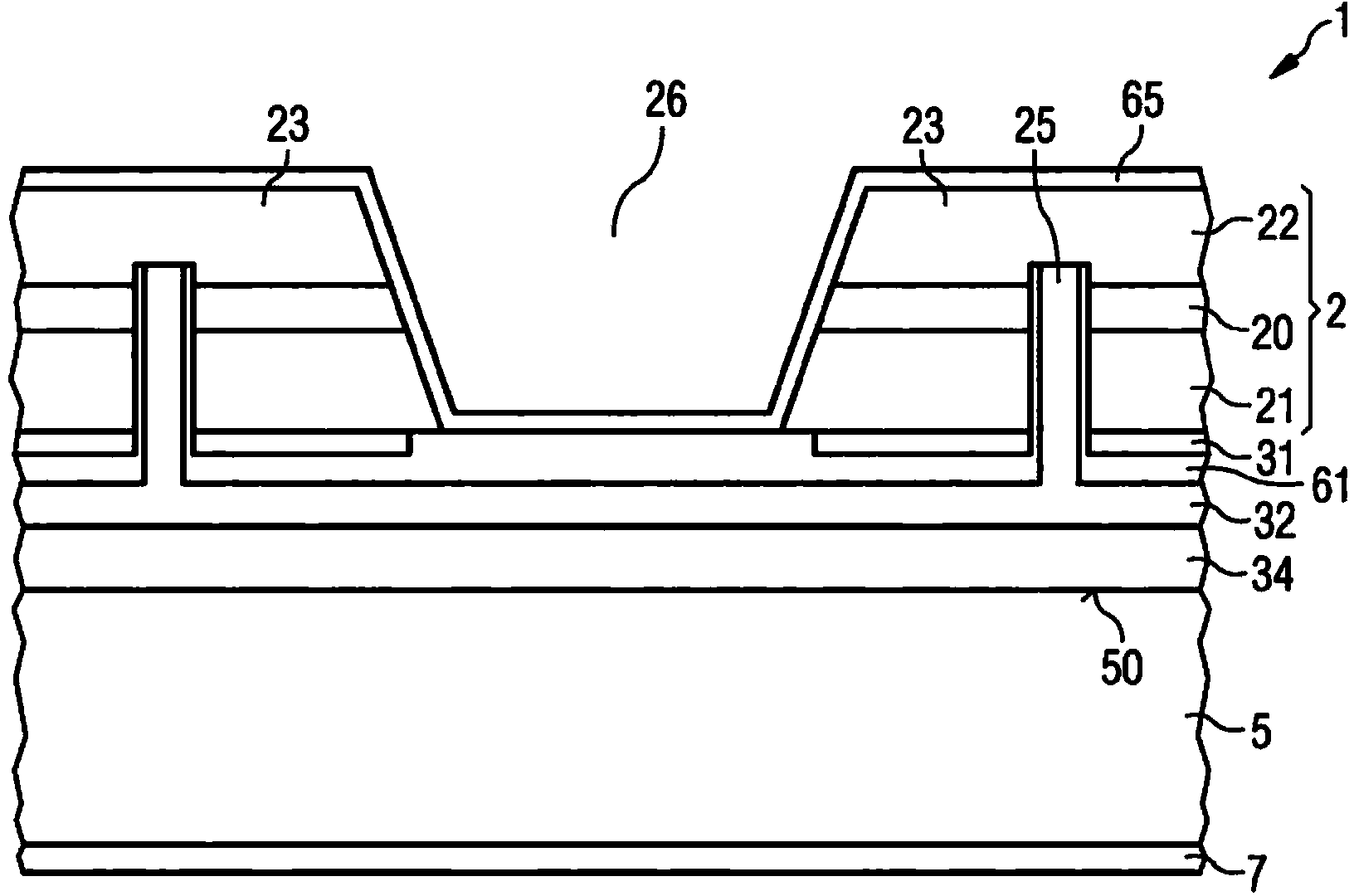

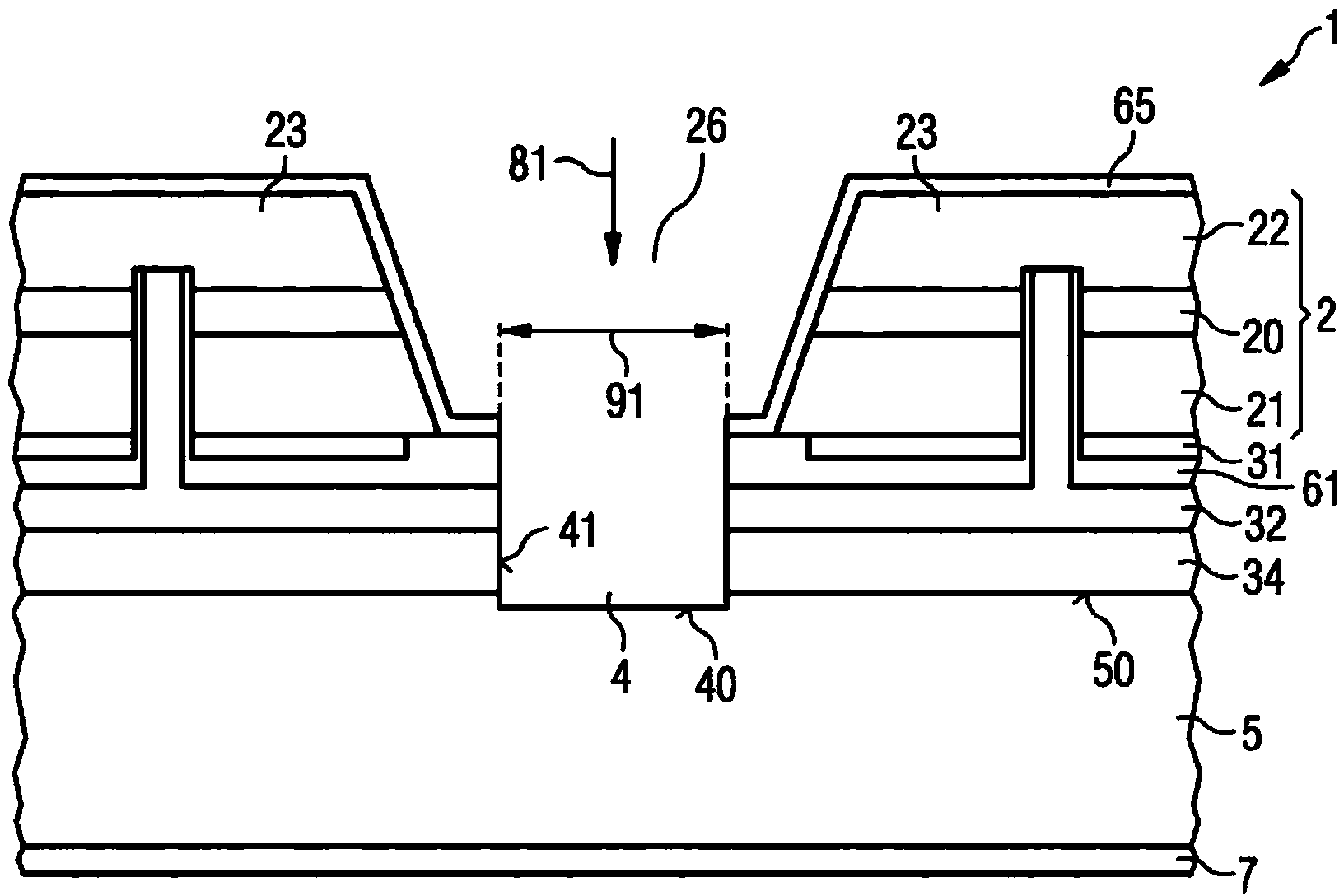

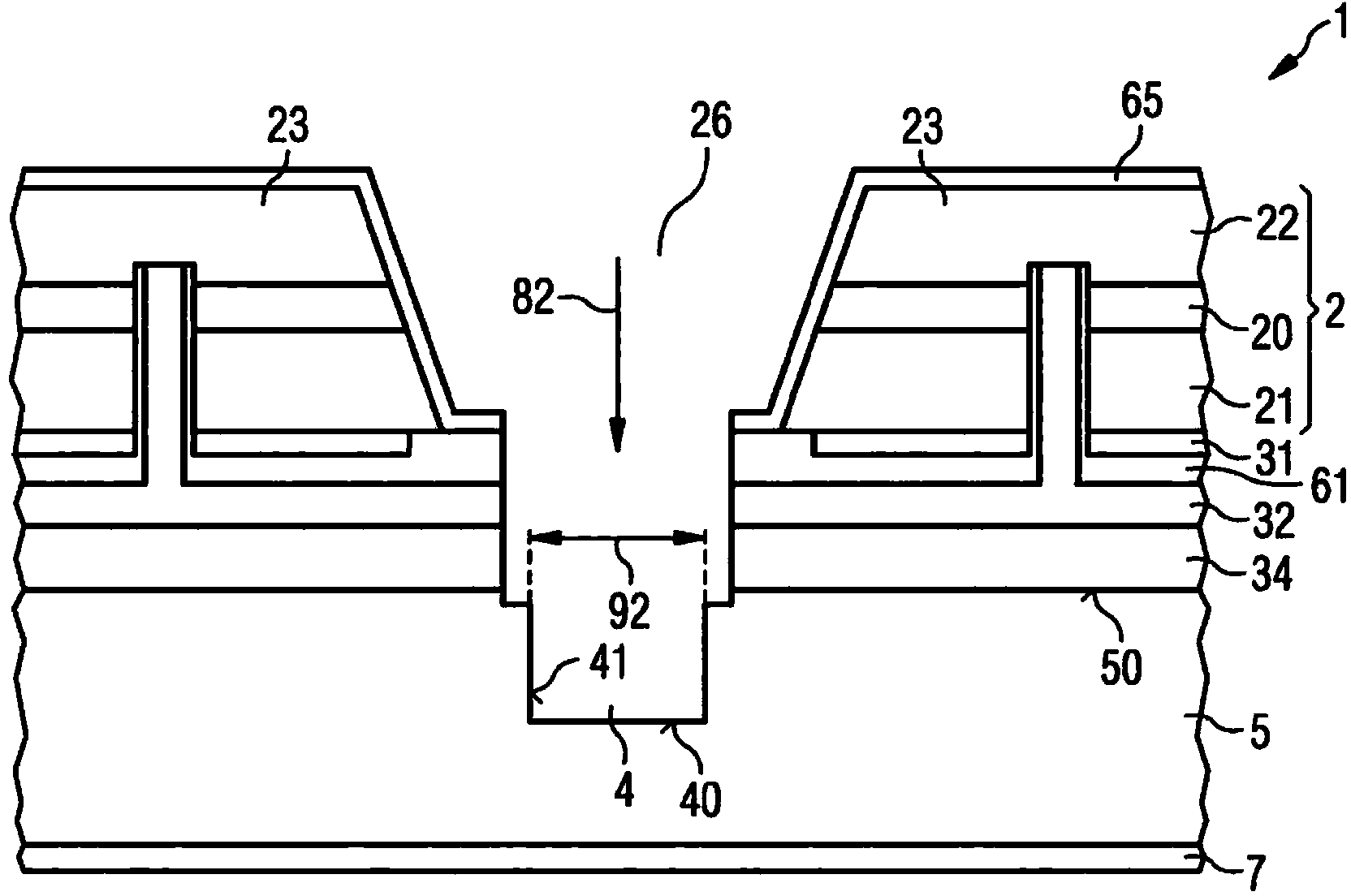

[0031] in Figure 1 to 5 A schematic cross-sectional view of a part of the semiconductor device composite 1 is shown in each. The method is described by way of example with the aid of the following semiconductor device assembly from which an optoelectronic semiconductor chip, in particular a light-emitting diode chip, is obtained during separation.

[0032] The semiconductor component assembly 1 has a carrier 5 with a main surface 50. The semiconductor layer sequence 2 is arranged on the main surface. The semiconductor layer sequence has an active area 20 provided for generating radiation. The active reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com