A separation and recovery machine for stubble and residual film

A technology for recycling machines and residual film, which is applied in the direction of collectors, harvesters, crop processors, etc., can solve the problems of low enthusiasm for recycling residual film, insufficient performance, and long time consumption, so as to eliminate insect eggs and breeding places, Shorten the operation link and improve the effect of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

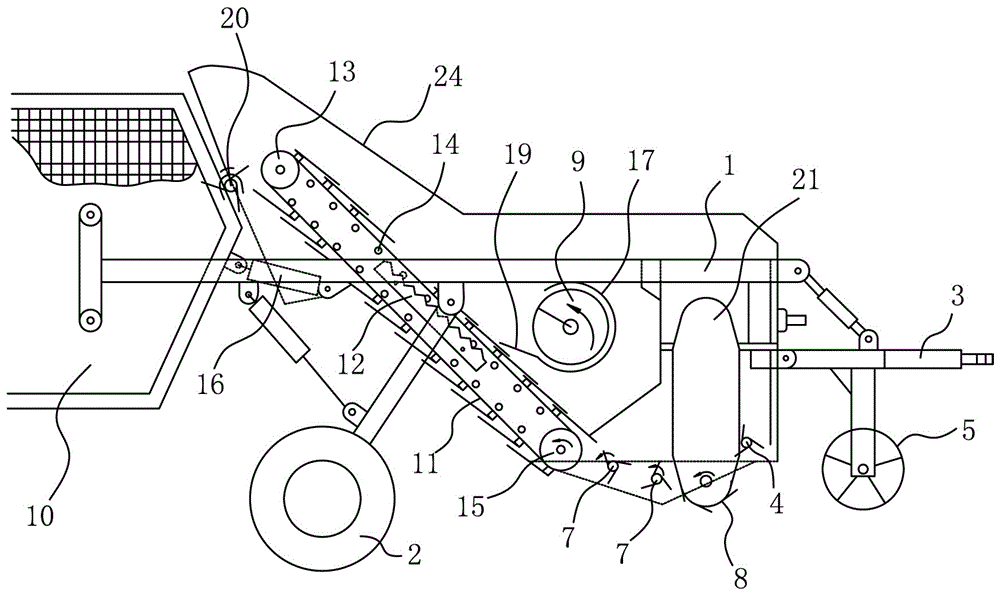

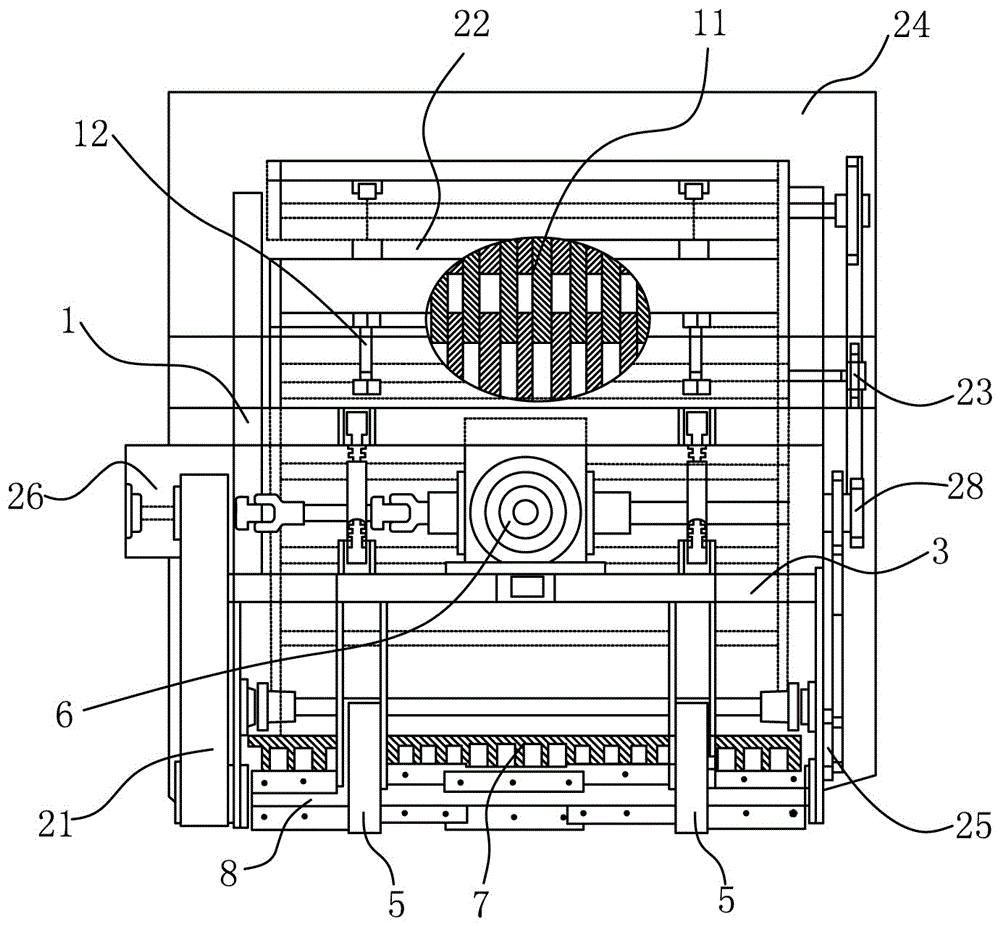

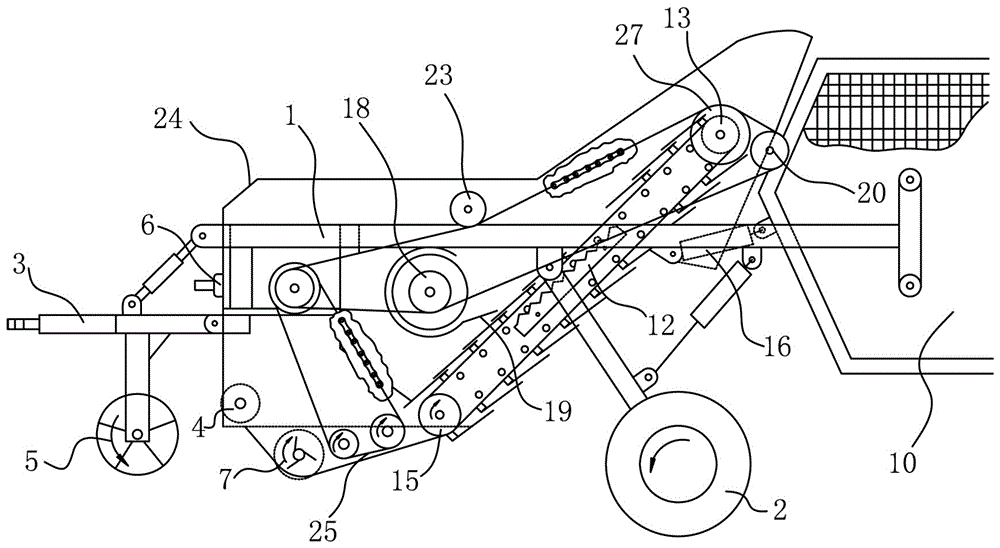

[0026] like Figure 1-3 As shown, a kind of root stubble and residual film separation and recovery machine described in the embodiment of the present invention mainly includes a main frame 1, a traveling device 2, a double-support traction frame 3 and a pulling wheel 4, a traveling device 2 and a double-support traction frame 3 are all connected with the main frame 1, the double support traction frame 3 is located in the front of the main frame 1, the limited depth wheel 5 is arranged on the double support traction frame 3, the depth limit wheel 5 is located at the both sides of the double support traction frame 3 below, and the pulling wheel 4 is located on the rear side of the depth-gauge wheel 5 and is fixed on the main frame 1. The recovery machine also includes a double-steering gearbox 6, a primary separation rotary roller 7, and a secondary chain row hole band-shaped shaking type film-soil separation device. The steering gearbox 6 is fixed directly in front of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com