Full-automatic juice degasser

A degasser, fully automatic technology, applied in the direction of food science, etc., can solve the problems of unstable degassing pressure, inaccurate liquid level control, wear and other problems, and achieve accurate and reliable degassing time, precise degassing pressure and liquid level Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

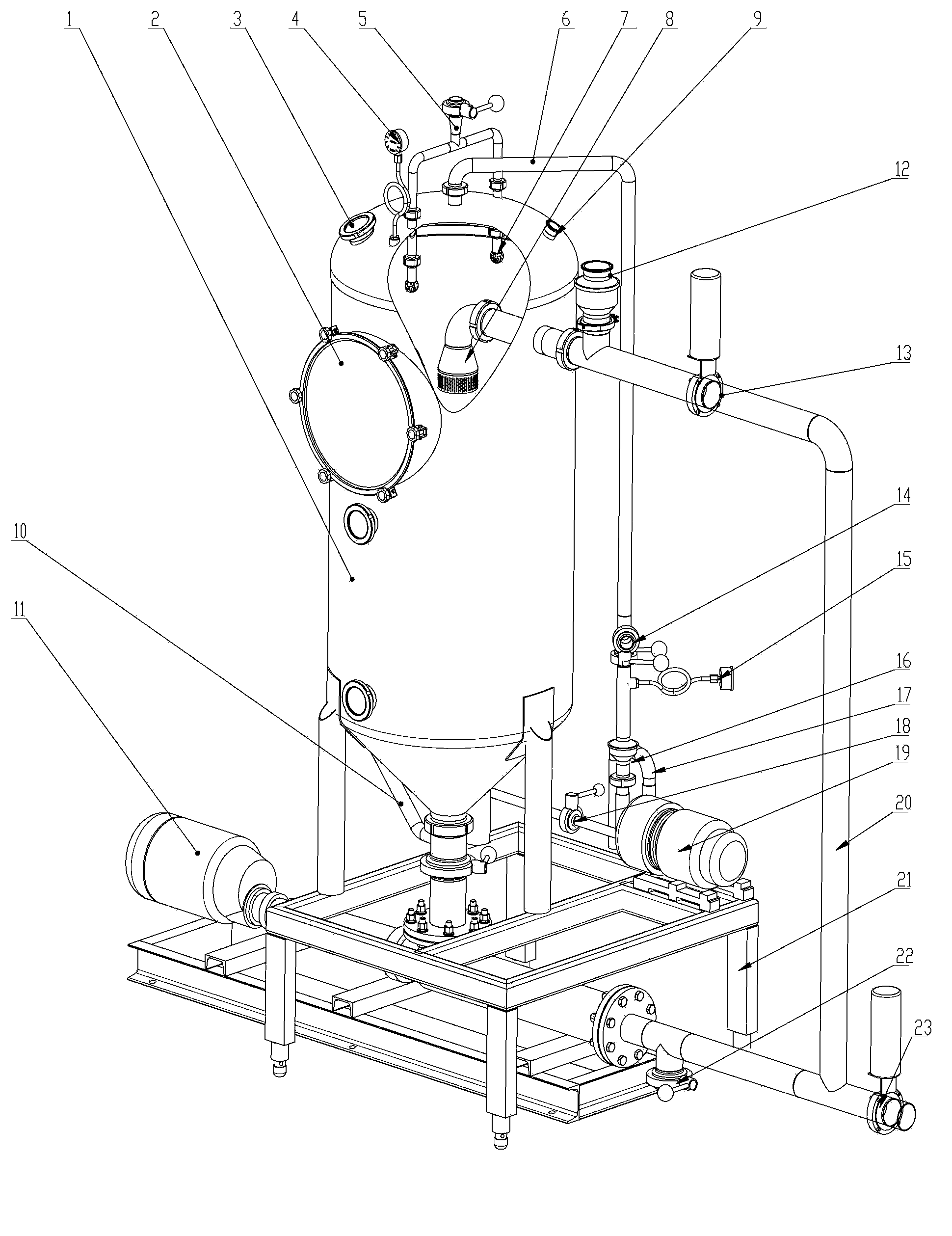

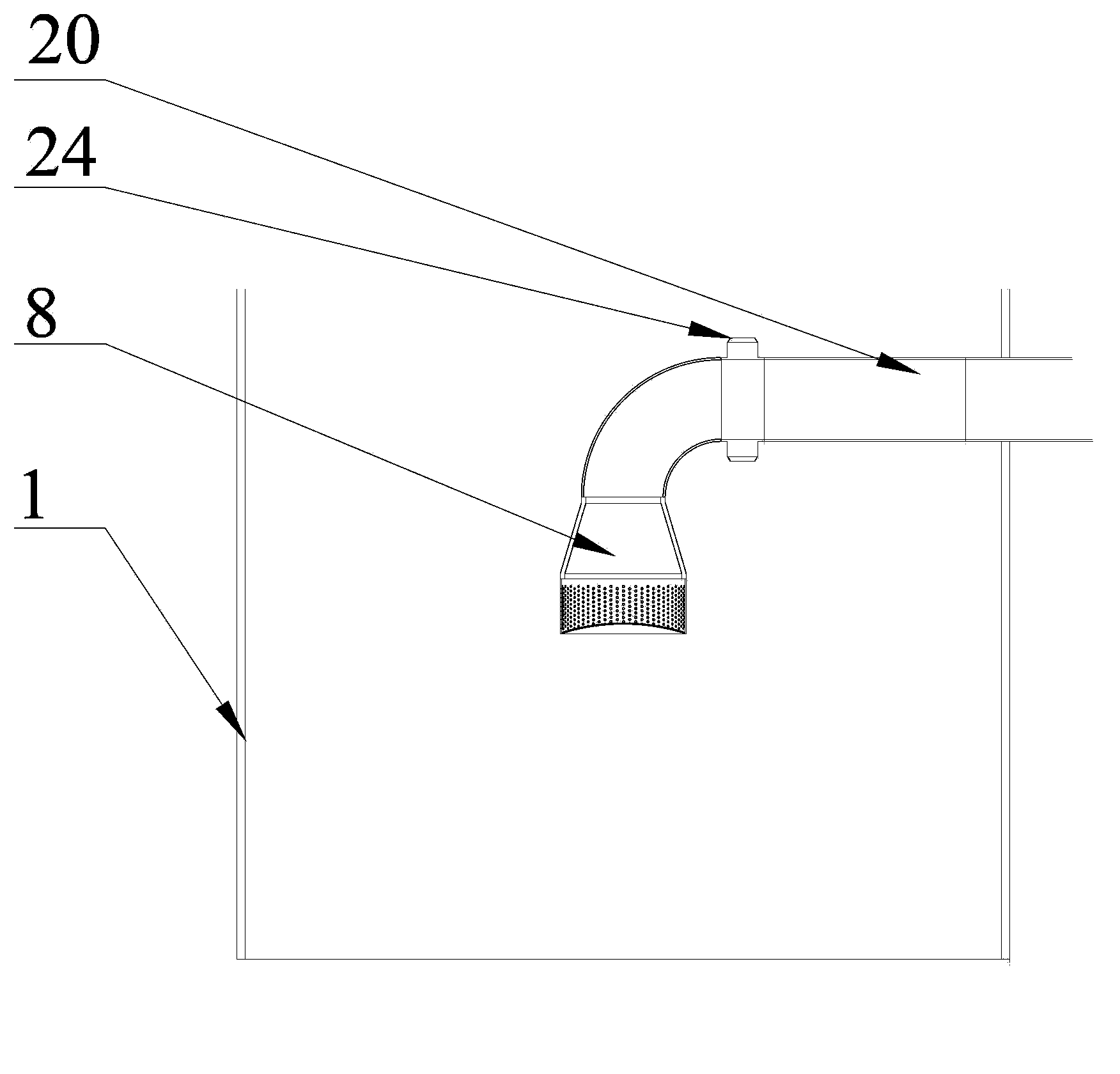

[0027] A fully automatic fruit juice degasser, such as figure 1 and figure 2 As shown, the degasser includes a tank body 1, a feeding device, a discharging device and a vacuum degassing device. The outside of the tank body 1 is provided with a return pipe whose bottom end is connected to the bottom of the tank body 1 and whose top end extends into the tank body 1. One end of the return line 20 extending into the inside of the tank body 1 is provided with a nozzle 8, the return line 20 is provided with a return valve 13, and the feeding device is connected between the return valve 13 and the tank body 1 through the return check valve 12. On the return line 20 between, the discharge device is located at the lower end of the return line 20, and the vacuum degassing device includes a vacuum pump 19 connected to the vacuum pump 6 connected to the top of the tank body 1 and the vacuum pump 6. The degasser also includes a CIP cleaning device. The CIP cleaning device includes a CIP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com