Oil-water separator for heat treatment production line

An oil-water separator and production line technology, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve problems such as affecting the appearance of workpieces, oil splashing, loss of function, etc., achieving a high degree of automation, a wide range of uses, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

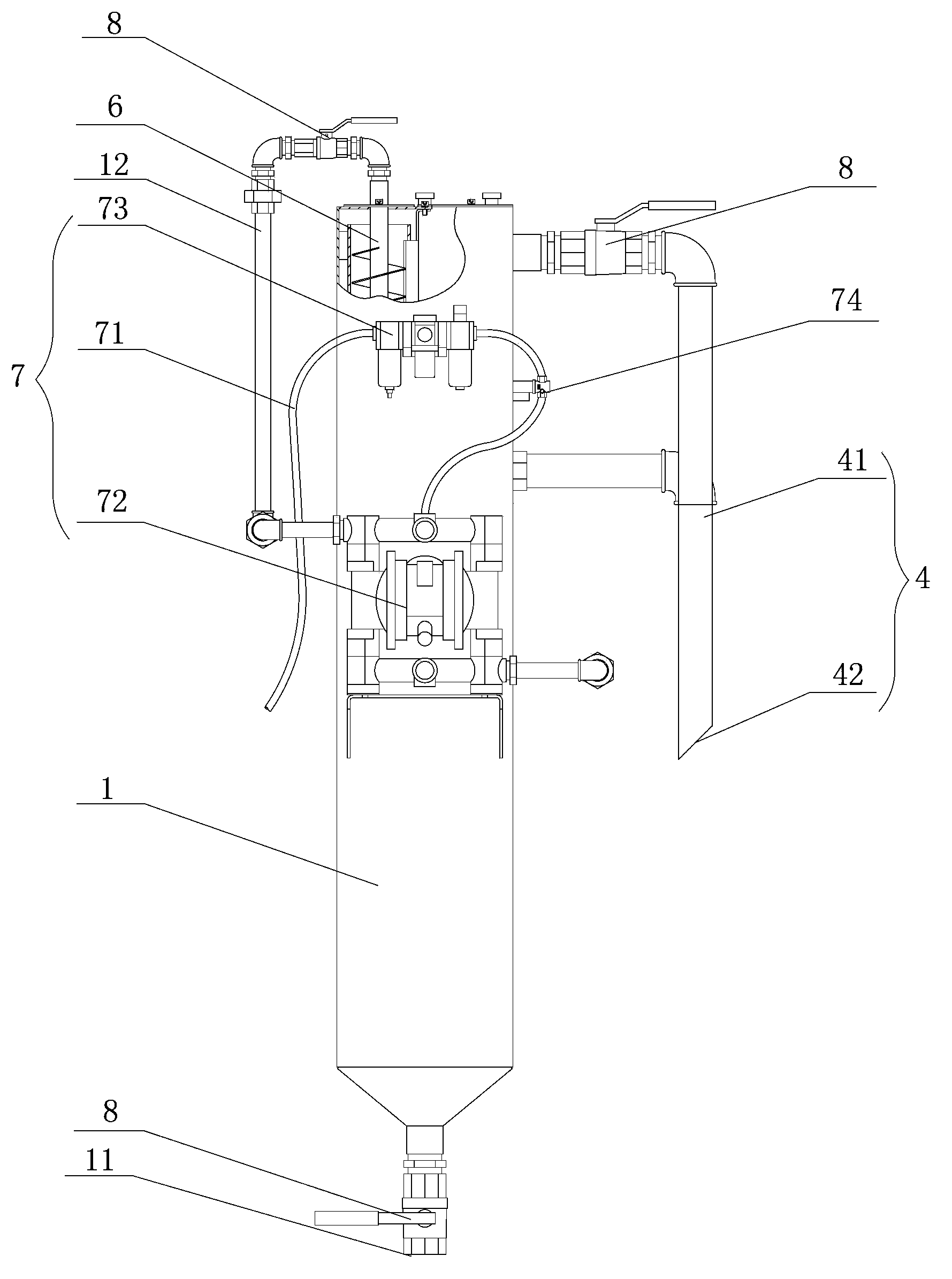

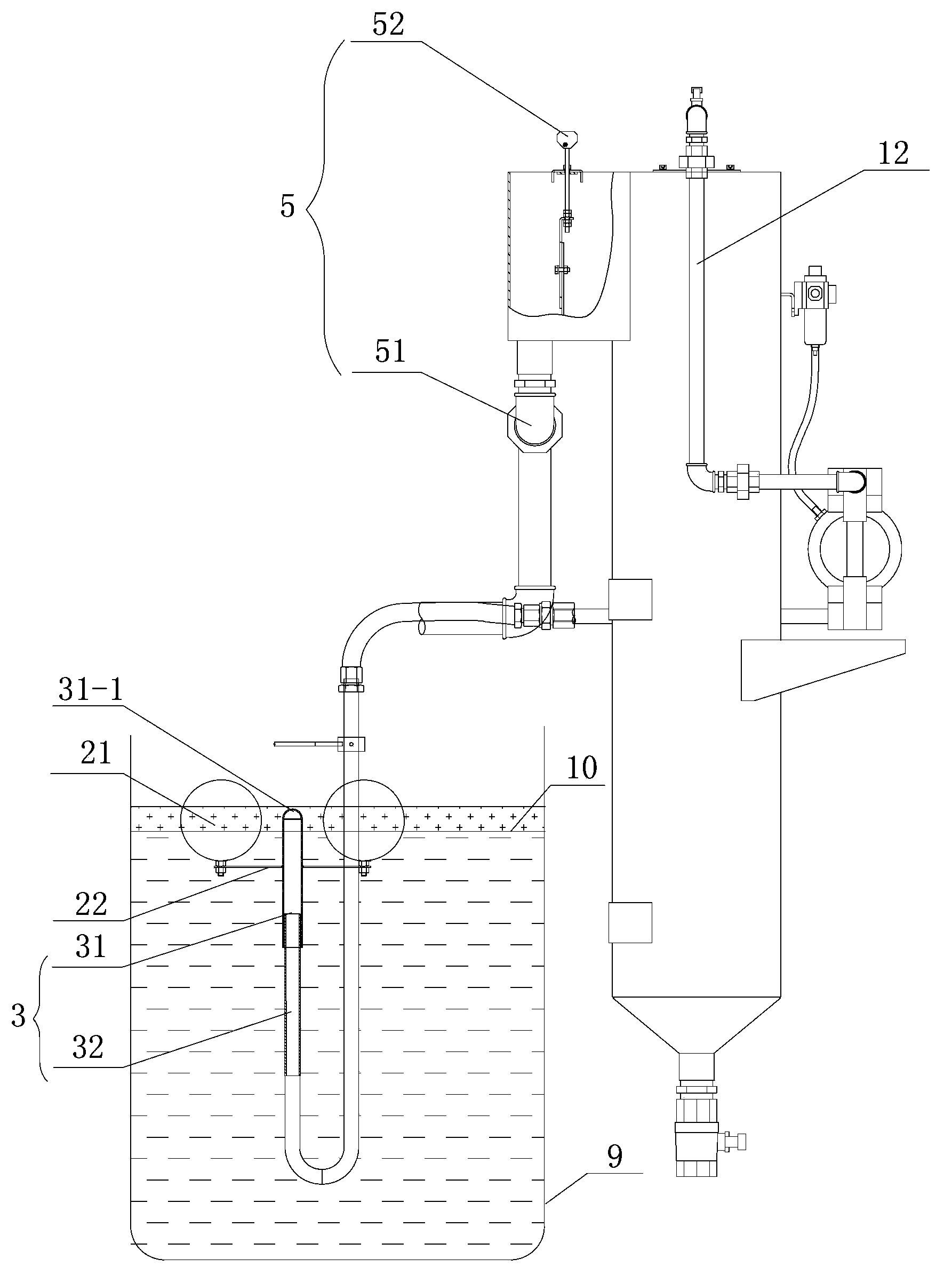

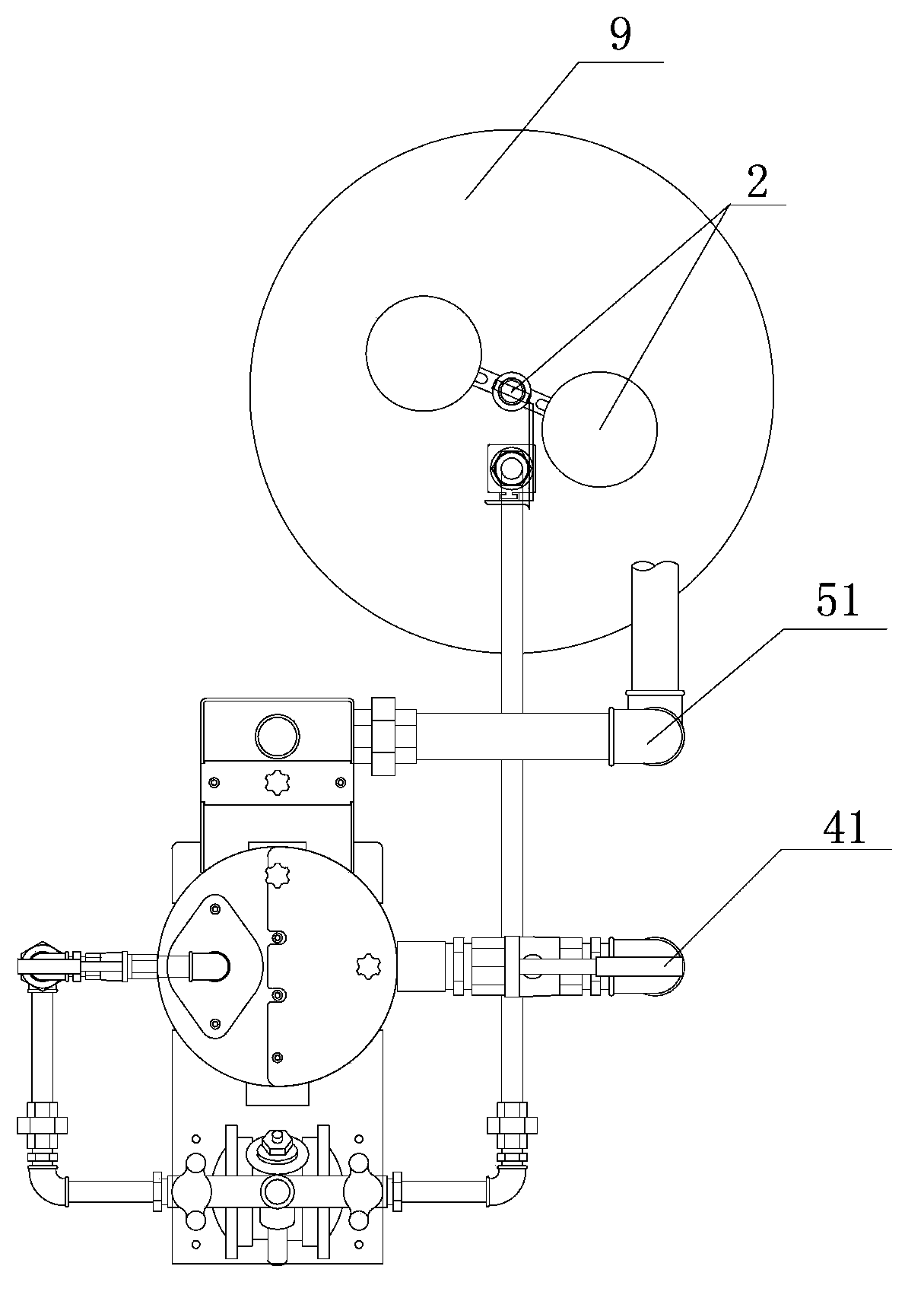

[0024] See Figure 1 to Figure 3 , the present invention has a vertically arranged cylindrical barrel 1 and an oil absorbing device 3 connected to the barrel 1 through a pipeline. The oil absorbing device 3 is located in the oil-water tank 9 next to the barrel 1. Position tracking device 2; also includes oil discharge device 4 and drainage device 5, oil discharge device 4 and drainage device 5 are connected to cylinder 1 through pipes; Oil suction starting device 7 is arranged. The lower part of the cylinder body 1 is frustum-shaped, and the lower end of the cylinder body 1 is provided with a sewage outlet 11, which is used to discharge the remaining solid dirt after oil-water separation. A stainless steel ball valve 8 is provided between the sewage outlet 11 and the cylinder body 1, which can facilitate the control of sewage discharge.

[0025] The oil suction device 3 comprises an oil suction sleeve 31 and an oil suction pipe 32 with an oil suction port 31-1 on the upper e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap