Method for cleaning coating film reworked sheet

A technology for the surface of silicon wafers and silicon wafers, which is applied in the field of cleaning of coated reworked wafers, can solve the problems that easily lead to the high proportion of flower wafers and cell wafers, and affect the battery performance, so as to improve production efficiency and quality efficiency, and solve the problem of battery performance. Poor, optimized appearance and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of cleaning method of coating rework sheet, comprises the following steps:

[0023] (1) Put the coating rework sheet into 15wt% HF solution, soak for 1200s, and remove the silicon nitride film deposited on the surface of the silicon wafer;

[0024] (2) Put the silicon wafer into deionized water at normal temperature, and wash it by bubbling for 200s;

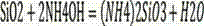

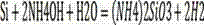

[0025] (3) Put the silicon wafer into the H 2 o 2 and NH 4 OH mixed solution containing 14wt% H 2 o 2 , 14wt%NH 4 OH, 1wt% surfactant and 71wt% deionized water, the temperature is controlled at 75°C, and the reaction time is 100s to remove ions and particles attached to the surface of the silicon wafer and improve the texture of the texture;

[0026] (4) Put the silicon wafer into deionized water at room temperature, and overflow wash it for 200s;

[0027] (5) Put the silicon chip into 5wt% HF solution at normal temperature, react at normal temperature for 210s, remove the oxide layer, and make...

Embodiment 2

[0031] Embodiment 2: the cleaning method of another kind of coating rework sheet, comprises the following steps:

[0032] (1) Put the coating rework sheet into 10wt% HF solution, soak for 900s, and remove the silicon nitride film layer deposited on the surface of the silicon wafer;

[0033] (2) Put the silicon wafer into deionized water at normal temperature, and wash it by bubbling for 250s;

[0034] (3) Put the silicon wafer into the H 2 o 2 and NH 4 OH mixed solution containing 13wt% H 2 o 2 , 7wt%NH 4 OH, 5wt% surfactant and 75wt% deionized water, the temperature is controlled at 85°C, and the reaction time is 50s to remove ions and particles attached to the surface of the silicon wafer and improve the texture of the texture;

[0035] (4) Put the silicon wafer into deionized water at normal temperature, and overflow wash it for 250s;

[0036] (5) Put the silicon chip into 5wt% HF solution at normal temperature, react at normal temperature for 210s, remove the oxide ...

Embodiment 3

[0040] Embodiment 3: another kind of cleaning method of coating rework sheet, comprises the following steps:

[0041] (1) Put the coating rework sheet into 20wt% HF solution, soak for 1800s, and remove the silicon nitride film layer deposited on the surface of the silicon wafer;

[0042] (2) Put the silicon wafer into deionized water at normal temperature, and wash it by bubbling for 300s;

[0043] (3) Put the silicon wafer into the H 2 o 2 and NH 4 OH mixed solution containing 20wt% H 2 o 2 , 12wt%NH 4 OH, 3wt% surfactant and 65wt% deionized water, the temperature is controlled at 65°C, and the reaction time is 200s to remove ions and particles attached to the surface of the silicon wafer and improve the texture of the texture;

[0044] (4) Put the silicon wafer into deionized water at room temperature, and overflow wash it for 200s;

[0045] (5) Put the silicon chip into 5wt% HF solution at normal temperature, react at normal temperature for 210s, remove the oxide lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com