Variable parameter control holing method for laminated structure of aircraft

A technology of laminated structure and variable parameters, used in automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as uncontrollable product processing quality, improve hole-making efficiency, avoid tool replacement, and ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

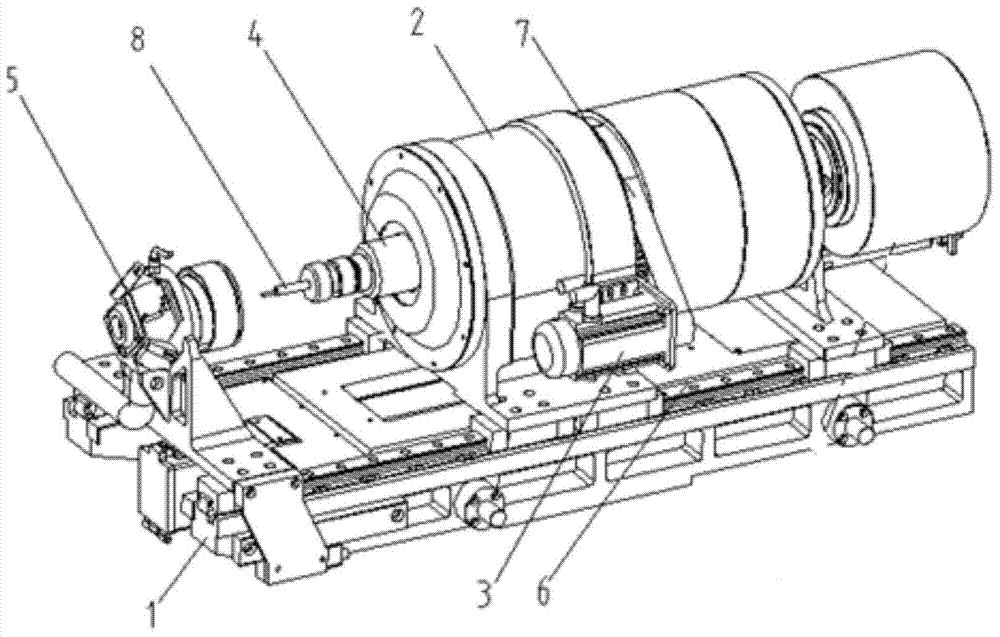

[0038] Such as figure 1 As shown, a screw hole-making end effector is fixed on a CNC machine tool, and is driven to a designated position by the CNC machine tool to make holes on the workpiece. It includes a base 1, a straight line set on the base Guide rail 6, a ram slidingly matched with the rail 6, an eccentric sleeve 2 and a revolution servo motor 3 fixed on the ram for cooperation through a synchronous belt 7, a mutually cooperating motor and electric spindle arranged in the eccentric sleeve 4, installation A cutter 8 on the electric spindle 4 and a presser foot 5 slidingly engaged with the base.

[0039] The drive motor and the ball screw pair matched with the drive motor are fixed on the base. The ball screw pair includes a screw and a nut, and the nut is fixed with the ram. Drive the ram to move on the track, that is, the tool moves on the track.

[0040] A cylinder is also fixed on the base, and the piston rod of the cylinder is fixed to the presser foot 5, which dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com