Preparation method of ultrasonic transducer for concrete structure detection/monitoring

A technology of ultrasonic transducers and concrete structures, applied in directions such as fluids that utilize vibrations, can solve the problem of the inability to radiate or receive sound waves in a horizontal 360° direction, the difficulty in controlling and adjusting the size of prestress, and the inability to detect/receive with concrete structures Monitoring and other issues, to achieve the effect of simple preparation method, simple structure and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

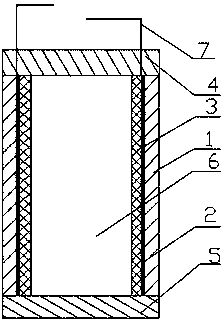

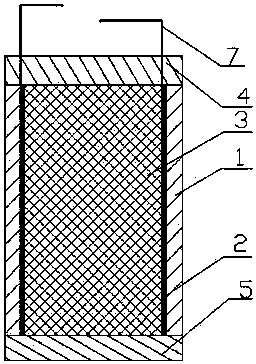

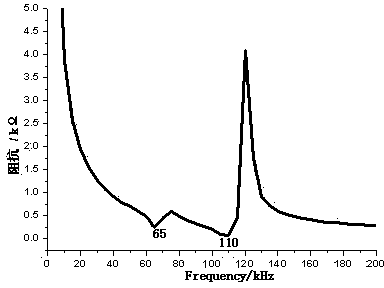

[0043] The structure schematic diagram of ultrasonic transducer of the present invention is as figure 1 As shown, it includes a piezoelectric element 2 and a packaging layer. The piezoelectric element is in the shape of a circular tube. Silver electrodes are arranged on the inner and outer surfaces of the piezoelectric element, wherein the inner surface is a positive electrode, the outer surface is a negative electrode, and the positive and negative electrodes are respectively The wires 7 are welded, and the welding points of the positive and negative wires are on the same horizontal plane, and the two welding points are centrally symmetrical, with the center line of the cylindrical piezoelectric element as the axis of symmetry. The inner and outer surfaces of the piezoelectric element, as well as the top and bottom ends are covered with encapsulation layers. Among them, the outer surface encapsulation layer 1 is located on the outer surface of the piezoelectric element, which ...

Embodiment 2

[0049] Prepare a radial composite ultrasonic transducer with the structure of the present invention and is suitable for embedding in concrete. The material of the surface encapsulation layer is ordinary silicate 42.5R cement with a mass ratio of 1:1:0.02:0.02, 197 heat-resistant unsaturated polyester resin (polyester resin for short, the same below), methylhexanone peroxide and naphthenic acid A mixture of cobalt, the inner surface, top and bottom of the encapsulation layer material is ordinary Portland 42.5R cement with a mass ratio of 1:1:0.25:0.1, E51 epoxy resin, T-31 and epoxy reactive diluent 678. The thickness of the encapsulation layer on the inner surface is 3mm, the thickness of the encapsulation layer on the outer surface is 3mm, and the thickness of the encapsulation layer on the top and bottom is 2mm.

[0050] Prepared by pouring process, the preparation process is as follows:

[0051] (1) Take the PZT-4 piezoelectric ceramic round tube with silver-fired inner a...

Embodiment 3

[0060]Prepare a radial compound ultrasonic transducer suitable for embedding in concrete with the structure of the present invention, the transducer structure is as in Example 1, the piezoelectric element is a PZT-4 piezoelectric ceramic circular tube, and the PZT-4 piezoelectric ceramic The inner diameter of the ceramic round tube is 14.00mm, the outer diameter is 18.00mm, and the height is 17.00mm. The outer surface encapsulation layer material is ordinary silicate 42.5R cement with a mass ratio of 2:1:1:0.08, 197 heat-resistant unsaturated polyester resin (referred to as polyester resin, the same below), methylhexanone peroxide and naphthene A mixture of acid cobalt, the inner surface, top and bottom sealing layer materials are ordinary Portland 42.5R cement with a mass ratio of 1:3:1.2:0.1, E51 epoxy resin, T-31 and epoxy reactive diluent 678 . The outer diameter of the inner prestressed plastic pipe is 11mm, and the inner diameter of the outer prestressed plastic pipe is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com