`Method for integrally manufacturing hanging ring and infusion bag and bottle blank injection mold used in method

A manufacturing method and injection molding technology, applied in the field of infusion bags, can solve the problems of increased production workshop area, increased labor loss, and increased mold costs, and achieve the effects of low mold investment, reduced production sites, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

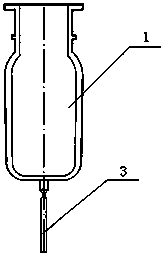

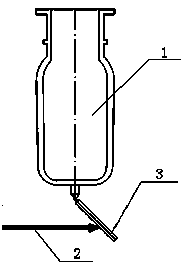

[0027] Such as Figure 1-4 As shown, this embodiment provides a manufacturing method for the integration of the suspension ring and the infusion bag, and the manufacturing method includes the following specific steps:

[0028] a) Injection molding preforms, the mixed medical raw materials are injection-molded into an infusion bottle (bag) preform 1 with a suspension ring 3 and preforms formed at one time through an integrated injection mold for suspension rings, and the width of the obtained preforms 1 is gradually increased from bottom to top reduced, the resulting preform is as figure 1 shown;

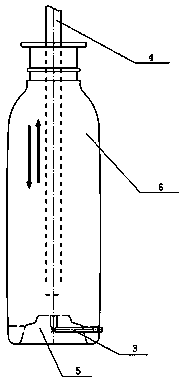

[0029] b) Pre-blowing molding: first, heat the preform 1 for temperature adjustment and finalization, so that the preform 1 has a certain temperature, which is conducive to blow molding, and then perform blow molding on the bottle body for the first time, and the bottle body of the obtained preform 1 is up and down. The width is the same; and the lifting ring 3 is pushed from one ...

Embodiment 2

[0035] Such as Figure 1-4 As shown, this embodiment provides a manufacturing method for the integration of the suspension ring and the infusion bag. The manufacturing method is two-step injection blow molding, including the following specific steps:

[0036] a) Injection molding preforms, the mixed medical raw materials are injection-molded into an infusion bottle (bag) preform 1 with a suspension ring 3 and preforms formed at one time through the integrated injection mold of the hanging ring, and the width of the obtained preform 1 is gradually increased from bottom to top Reduced, the resulting preform 1 such as figure 1As shown, after the injection molded preform is completed, the obtained preform 1 is placed and cooled for molding;

[0037] b) Pre-blowing molding: first, heat the preform 1 for temperature adjustment and finalization, so that the preform 1 has a certain temperature, which is conducive to blow molding, and then perform blow molding on the bottle body for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com