Method for printing anti-fake information pattern

A printing method and information pattern technology, applied in the field of printing, can solve the problems of high cost, poor precision and slow efficiency, and achieve the effect of high precision, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

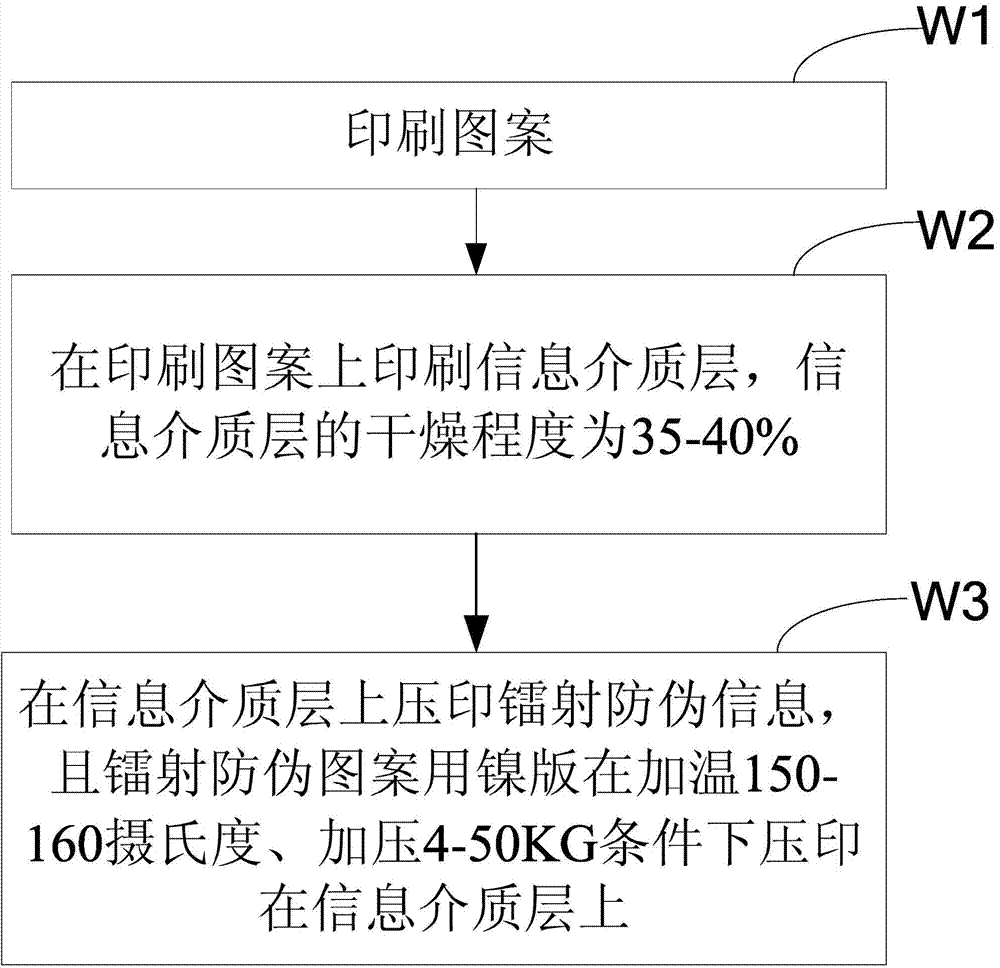

[0026] like figure 1 As shown, the invention discloses a printing method of an anti-counterfeiting information pattern, comprising the following steps:

[0027] Step W1: printing pattern;

[0028] Step W2: printing the information medium layer on the printed pattern, the dryness of the information medium layer is 35-40%;

[0029] Step W3: embossing laser anti-counterfeiting information on the information medium layer, and embossing the laser anti-counterfeiting pattern on the information medium layer under the conditions of heating 150-160 degrees Celsius and pressurizing 4-50KG with a nickel plate.

[0030] Nickel plate production method: engrave the pattern on the frosted glass, spray silver after engraving, and then electroplate nickel to make a nickel plate.

[0031] In step W2, the information medium layer is printed on the surface of the printed matter, the curing degree of the information medium layer is controlled by controlling the energy of the ultraviolet lamp, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com