Chemical mechanical polishing fluid for computer hard disk

A chemical machinery and polishing liquid technology, applied in the computer field, can solve the problems of reducing the surface roughness of hard disks, not involving removal rate and surface roughness, etc., to improve surface quality and processing efficiency, enhance dispersibility, and reduce requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

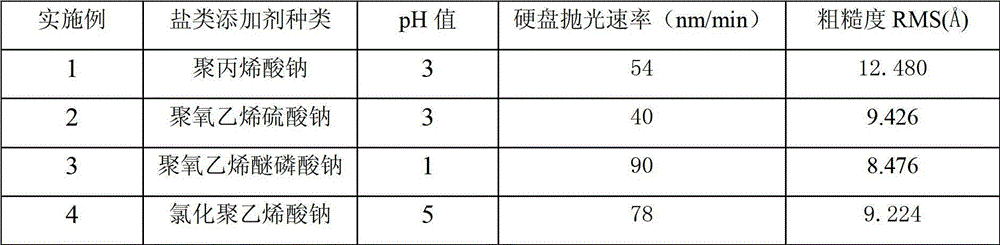

Examples

Embodiment 1

[0024] 1. Experimental equipment and reagents

[0025] 1) Instrument: CMPtester (CETRCP-4)

[0026] 2) The composition of computer hard disk chemical mechanical polishing fluid is as follows:

[0027] Abrasive particles: SiO with a radius of 10nm 2 5wt%;

[0028] Oxidant: hydrogen peroxide 2wt%;

[0029] Sodium polyacrylate 1wt%;

[0030] 0.1M hydrochloric acid was used to adjust the pH of the polishing solution to 3.0, and the solvent was deionized water.

[0031] 2. Detection method - hard disk 3.5-inch disc polishing test method

[0032] Condition: Pressure (DownForce): 5psi

[0033] Polishing pad speed (PadSpeed): 150rpm

[0034] Polishing head speed (CarrierSpeed): 150rpm

[0035] Temperature: 25°C

[0036] Polishing liquid flow rate (FeedRate): 150ml / min

[0037] Using the computer hard disk chemical mechanical polishing liquid prepared in this example as the polishing liquid, the hard disk is polished by the CP-4 polishing machine of the American CETR company,...

Embodiment 2

[0041] 1. Experimental equipment and reagents

[0042] 1) Instrument: CMPtester (CETRCP-4)

[0043] 2) The composition of computer hard disk chemical mechanical polishing fluid is as follows:

[0044] Abrasive particles: SiO with a radius of 50nm 2 1wt%;

[0045] Oxidant: Potassium ferricyanide 10wt%;

[0046] Sodium polyoxyethylene sulfate 0.5wt%;

[0047] 2M hydrochloric acid was used to adjust the pH of the polishing solution to 3.0, and the solvent was deionized water.

[0048] 2. Detection method - hard disk 3.5-inch disc polishing test method

[0049] Condition: Pressure (DownForce): 5psi

[0050] Polishing pad speed (PadSpeed): 150rpm

[0051] Polishing head speed (CarrierSpeed): 150rpm

[0052] Temperature: 25°C

[0053] Polishing liquid flow rate (FeedRate): 150ml / min

[0054]Using the computer hard disk chemical mechanical polishing liquid prepared in this example as the polishing liquid, the hard disk is polished by the CP-4 polishing machine of the Americ...

Embodiment 3

[0058] 1. Experimental equipment and reagents

[0059] 1) Instrument: CMPtester (CETRCP-4)

[0060] 2) The composition of computer hard disk chemical mechanical polishing fluid is as follows:

[0061] Abrasive particles: SiO with a radius of 80nm 2 10wt%;

[0062] Oxidizing agent: ammonium persulfate 2wt%;

[0063] Sodium polyoxyethylene ether phosphate 1.5wt%;

[0064] 0.1M hydrochloric acid was used to adjust the pH value of the polishing solution to 1.0, and the solvent was deionized water.

[0065] 2. Detection method - hard disk 3.5-inch disc polishing test method

[0066] Condition: Pressure (DownForce): 5psi

[0067] Polishing pad speed (PadSpeed): 150rpm

[0068] Polishing head speed (CarrierSpeed): 150rpm

[0069] Temperature: 25°C

[0070] Polishing liquid flow rate (FeedRate): 150ml / min

[0071] Using the computer hard disk chemical mechanical polishing liquid prepared in this example as the polishing liquid, the hard disk is polished by the CP-4 polishing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap