Rare earth and carbon co-penetration process of gear

A rare earth and co-permeation technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high carbon potential Cp, poor metallographic structure, and decreased accuracy level, and achieve accelerated carburizing process. , The effect of improving the performance of the seepage layer and improving the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

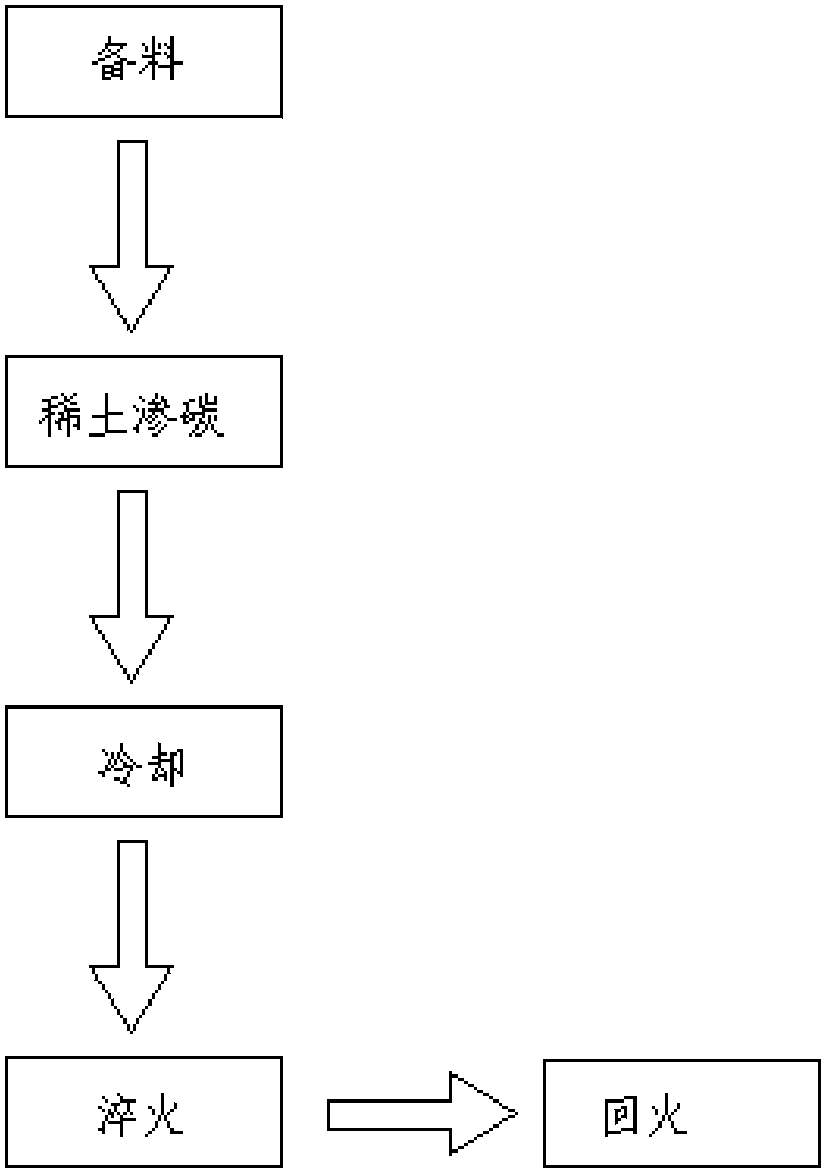

[0023] Referring to the accompanying drawings, a gear rare earth carburizing process is characterized in that: its process steps are as follows:

[0024] (1) Material preparation: Put the cleaned gear blank into the carburizing furnace and pour in the rare earth carburizing agent;

[0025] (2) Rare earth carburizing: the carburizing furnace heats the interior by means of staged heating;

[0026] (3) Cooling: After the temperature of the carburizing furnace reaches the standard, the heating system is turned off, and the gear blank is naturally cooled to 300°C;

[0027] (4) Quenching; place the carburized gear blank in a heating furnace and heat it to 800-850°C for 1 hour, then pour it into the quenching

[0028] cooling in fire medium;

[0029] (5) Low temperature tempering: the tempering temperature is 160-220°C, and the tempering time is 5h.

[0030] Described rare earth carburizing agent is calculated by weight percentage, and the formula of main raw material is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com