Cornice heat-preservation and plugging device for tensioned membrane roof

A plugging device and stretching membrane technology, applied in the direction of roofing, roof covering, roof insulation materials, etc., can solve the problems of heat loss, indoor temperature drop, etc., and achieve the effect of beautiful appearance, easy operation and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

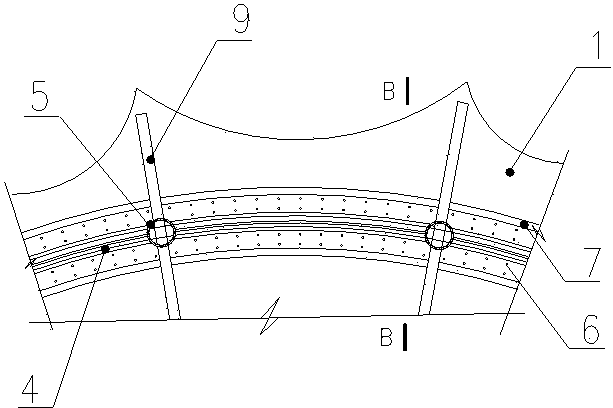

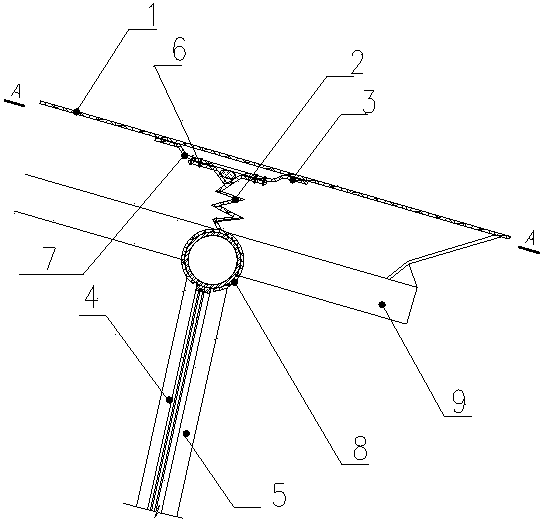

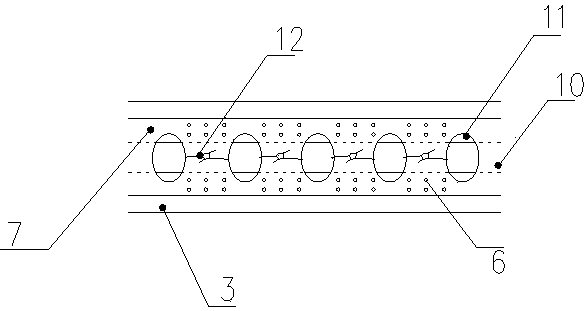

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] like figure 1 , figure 2 , image 3 and Figure 4 , a eaves insulation sealing device for tensioned membrane roofs, is characterized in that the device has: the fixed membrane material belt 7 is fixed on the membrane roof 1 through the heat welding seam 3, and the lower end of the sealing membrane material belt 2 is heat-shrinkable The type elastic clamp 16 is clamped on the steel structure beam 8, and the upper end of the sealing film strip 2 is fixed on the fixed film strip 7 with a rivet 6, and a glass wool insulation layer 15 is arranged in the middle of the sealing film strip 2, and the fixed film strip 7 The gap between the sealing membrane material band 2 is filled with glass wool insulation pillow belt 10, and the glass wool insulation pillow belt 10 is bound and fixed through the operating hole 11 on the fixed membrane material belt 7 with soft rope 12....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap