Aerogel complex fiber thermal insulation material and preparation method thereof

A composite fiber and thermal insulation material technology, applied in thermal insulation, building components, etc., can solve problems such as low mechanical strength, limited operability and application, and poor toughness, and achieve high safety performance, superior thermal insulation performance, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

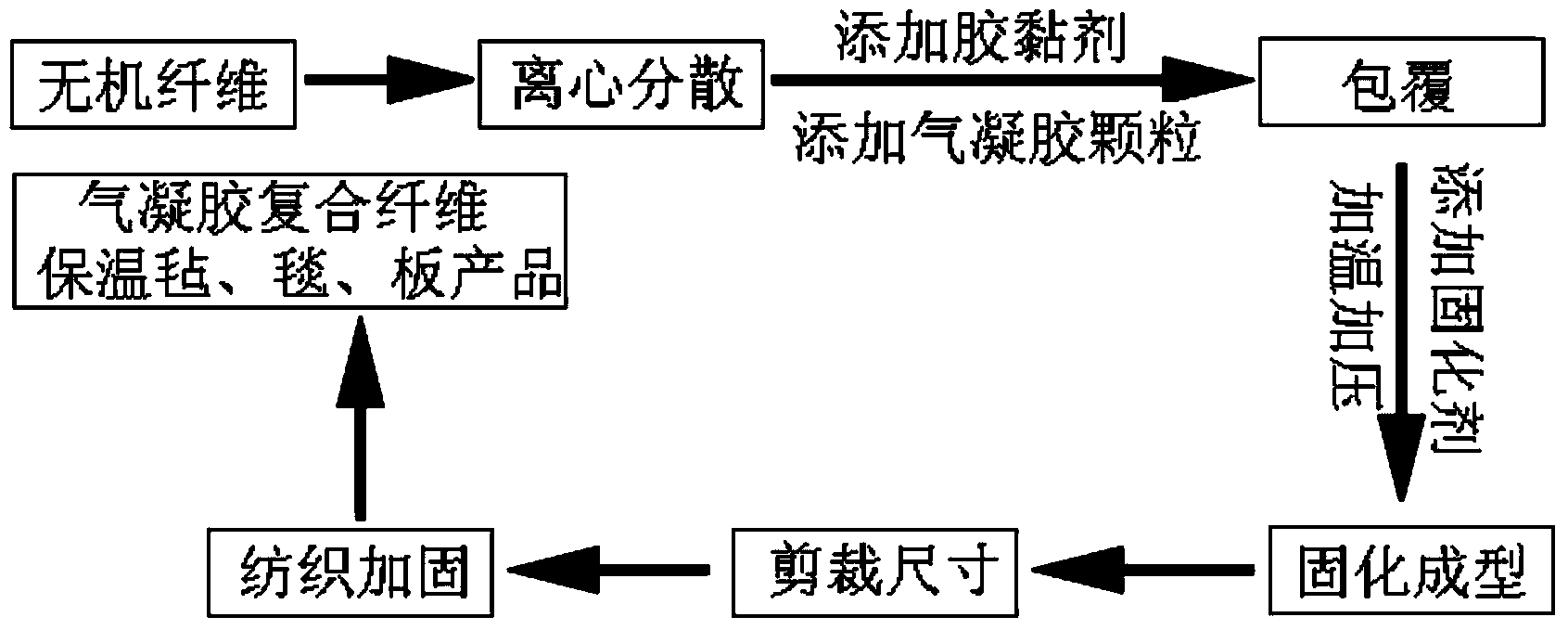

[0028] The preparation process of the airgel composite glass fiber insulation blanket of the present embodiment is as follows: figure 1 As shown, the specific steps are as follows:

[0029] (1) Coating process: put 1kg of glass fiber (fiber length 5mm, diameter 2μm) in a centrifuge to fully disperse to make it evenly dispersed; through an external spraying device, 0.5kg of the pre-prepared A-stage phenolic The resin adhesive is sprayed onto the surface of the glass fiber; then 3kg of prepared hydrophobic silica airgel particles (porosity greater than 80%, thermal conductivity less than 0.03w / m·k) are evenly sprayed onto the glass fiber in stages ; Spray the pre-prepared 0.05kg phthalic anhydride curing agent to the glass fiber surface covered by airgel particles again by an external spray device; in the above process, carry out under the constant working state of the stirring centrifuge;

[0030] (2) Curing molding process: Pour the airgel particle-coated glass fiber raw mate...

Embodiment 2

[0036] The preparation process of the airgel composite ceramic fiber insulation felt of the present embodiment is as follows: figure 1 As shown, the specific steps are as follows:

[0037] (1) Coating process: Place 5kg of ceramic fibers (fiber length 20mm, diameter 10μm) in a centrifuge and disperse them evenly; Spray the adhesive on the surface of the ceramic fiber; then spray the prepared 8kg hydrophobic silica airgel particles (porosity greater than 60%, thermal conductivity less than 0.03w / m·k) evenly on the inorganic fiber in stages; again Spray the pre-prepared 0.1kg trimethylchlorosilane curing agent on the surface of the ceramic fiber coated with airgel particles through an external spray device; in the above process, the stirring centrifuge is always working;

[0038](2) Curing molding process: Pour the airgel particle-coated ceramic fiber raw material prepared in the above process into the prefabricated mold, heat at 80°C, and pressurize 5000kN to make it solidify ...

Embodiment 3

[0044] The preparation process of the airgel composite rock wool fiber insulation board of the present embodiment is as follows: figure 1 As shown, the specific steps are as follows:

[0045] (1) Coating process: Put 10kg of rock wool fibers (50mm in length and 80μm in diameter) in a centrifuge to disperse them evenly; Spray the oxygen resin adhesive onto the surface of the inorganic fiber; then spray the prepared 1.25kg hydrophobic airgel particles (with a porosity greater than 60% and a thermal conductivity less than 0.03w / m·k) onto the rock wool fiber in stages; Spray the pre-prepared 0.0625kg of phthalic anhydride curing agent on the surface of the inorganic fiber coated with airgel particles through the external spraying equipment again; in the above process, it is carried out under the constant working state of the stirring centrifuge;

[0046] (2) Curing molding process: Pour the airgel particle-coated inorganic fiber raw material prepared in the above process into a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com