Hot forming cylindrical workpiece geometrical parameter detection device and method

A technology of geometric parameters and detection devices, applied in the direction of measuring devices, instruments, etc., can solve the problems of lack of recording devices, affecting test accuracy, irregularities, etc., and achieve the effects of improving detection efficiency, reducing labor intensity, and increasing life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

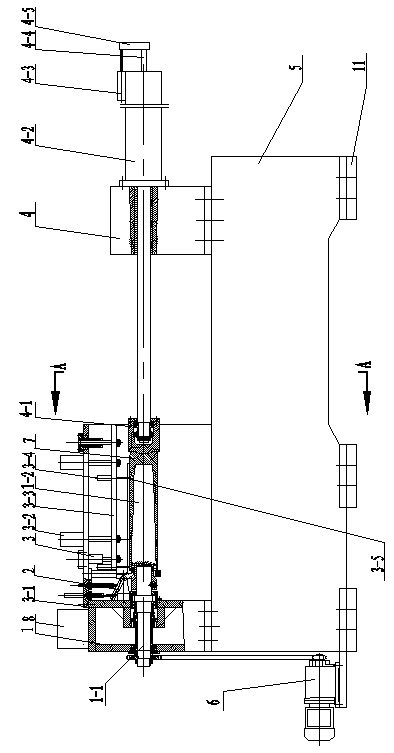

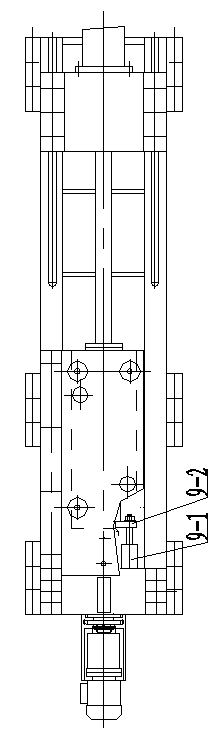

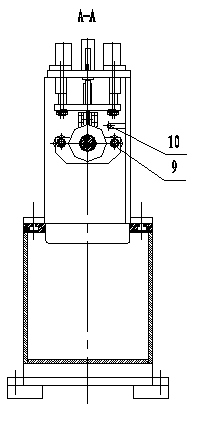

[0016] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a device for detecting geometric parameters of thermoformed cylindrical parts, including a bed 5, a headstock 1, and a wall thickness difference tester. Mechanism 3, tail top 4, transmission system 6, programmable controller 8 with display touch screen, spindle box 1 is fixed on one side of bed 5, transmission system 6 is fixed on the outside of this side, transmission system 6 drives spindle box 1 The main shaft 1-1, the workpiece 7 to be tested is installed on the mandrel 1-2 on the main shaft 1-1, the tail top 4 is fixed on the other side of the bed 5, and the wall thickness difference testing device 3 is above the main shaft 1-1. The device is provided with a fixed base 3-1 fixed on the bed 5, a movable base 3-3, two wall thickness difference LVDT sensors 3-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com