Sensor shell

A sensor and housing technology, applied in the field of housing, can solve the problems of great environmental impact, inability to reuse, and a large number of chemicals, to achieve the effects of improving conversion efficiency, easy to spray paint, and suppressing aftershocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

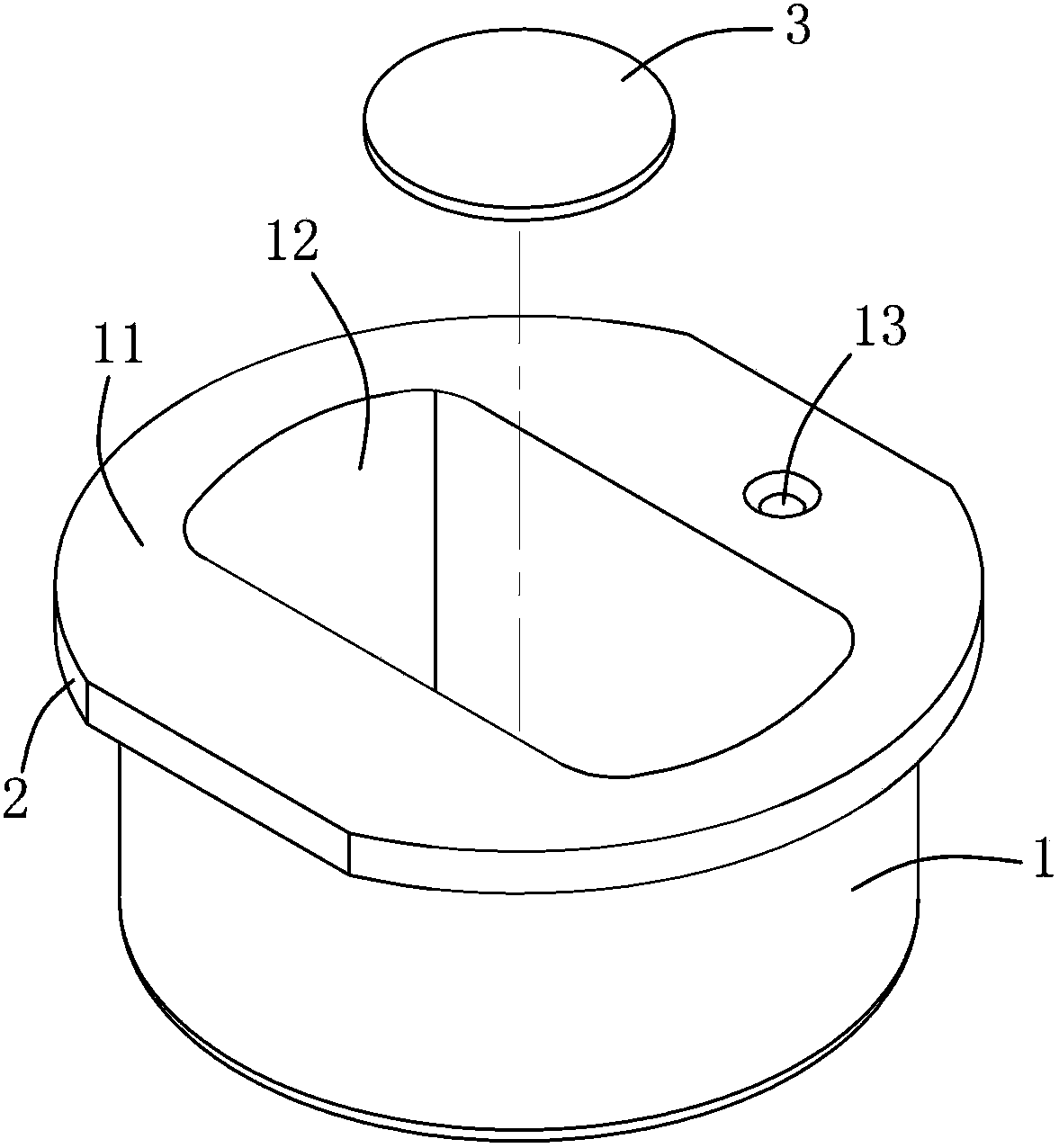

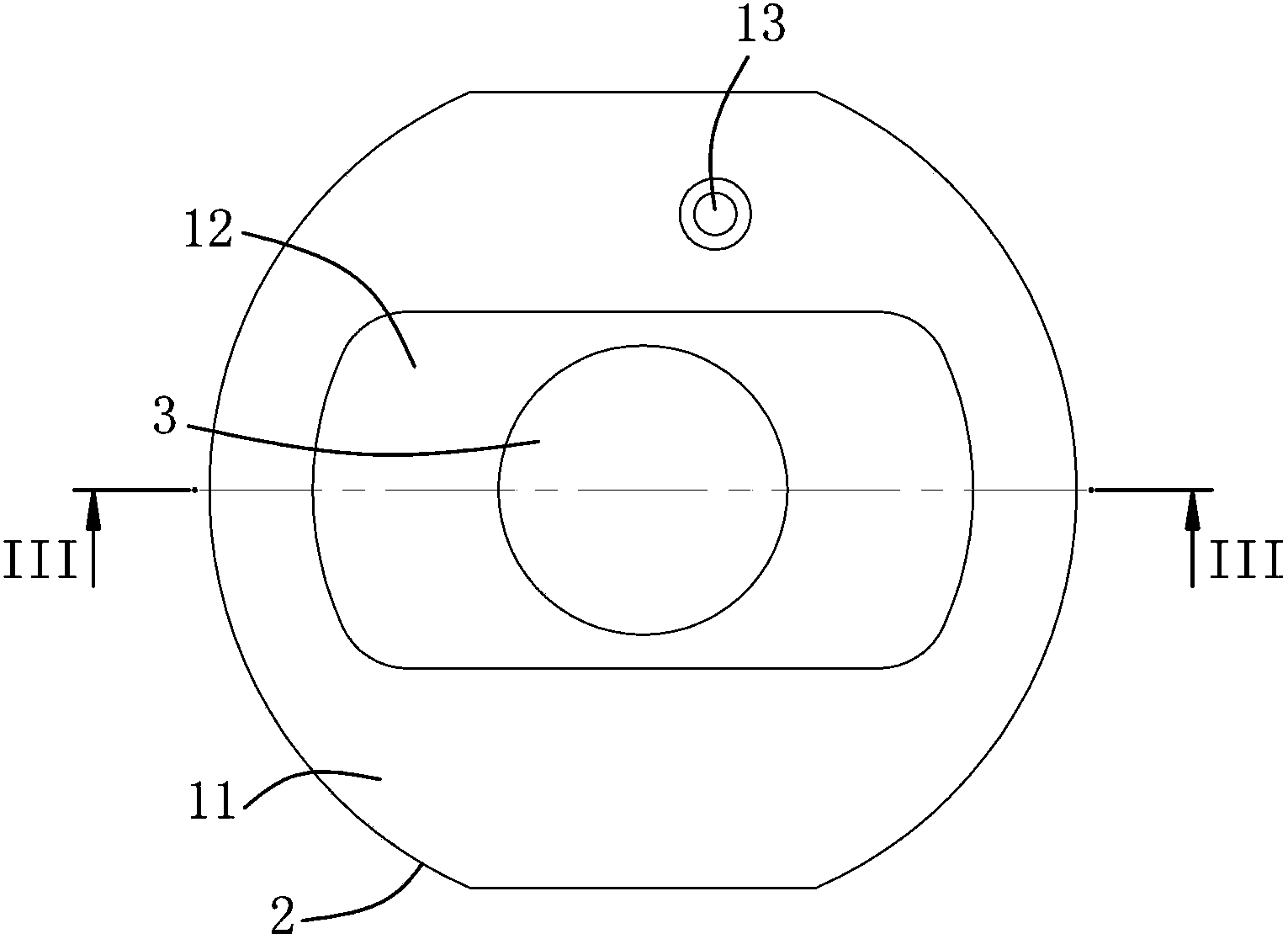

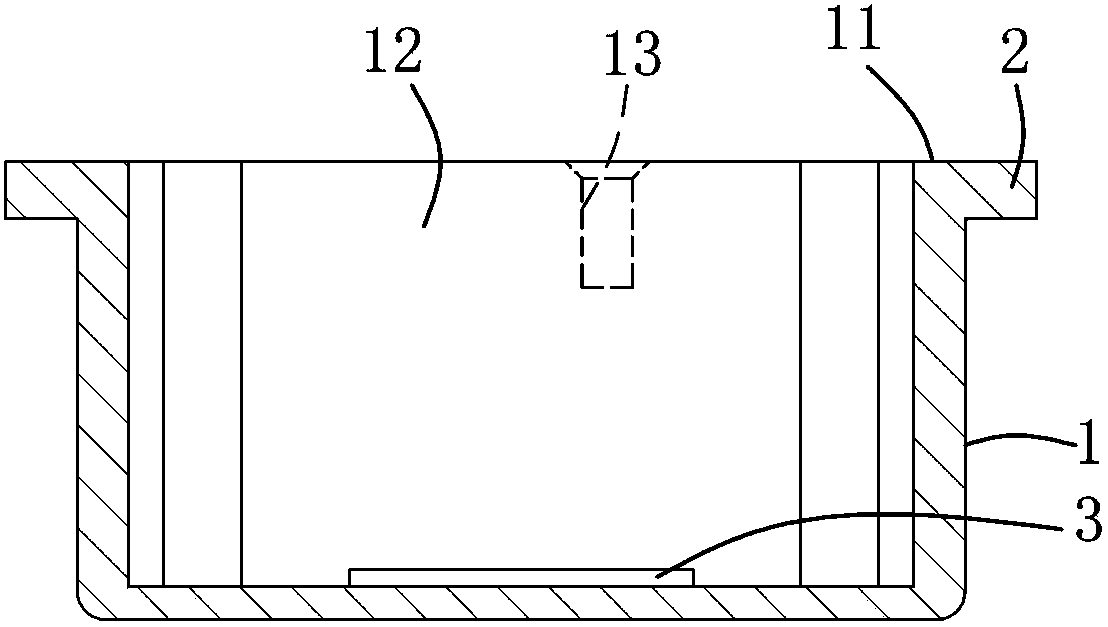

[0016] refer to figure 1 , figure 2 and image 3 , a preferred embodiment of the sensor housing of the present invention is suitable for setting a piezoelectric film 3 , this preferred embodiment includes a housing body 1 and a positioning protrusion 2 .

[0017] The shell body 1 has a top surface 11 , a cavity 12 formed by indentation of the top surface 11 , and a hole 13 formed by indentation of the top surface 11 for inserting a pin. The piezoelectric film 3 is disposed in the chamber 12 . After the pins are inserted into the holes 12, they can be electrically connected to the piezoelectric sheet 3 through the housing 1, thus saving steps during assembly.

[0018] The positioning protrusion 2 protrudes radially from the shell body 1 along the peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com