Wet type ball grinder load parameter integrated modeling method based on EEMD (ensemble empirical mode decomposition)

A wet ball mill, load parameter technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

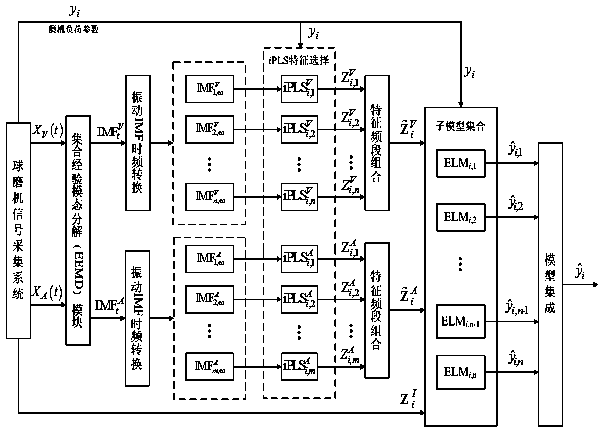

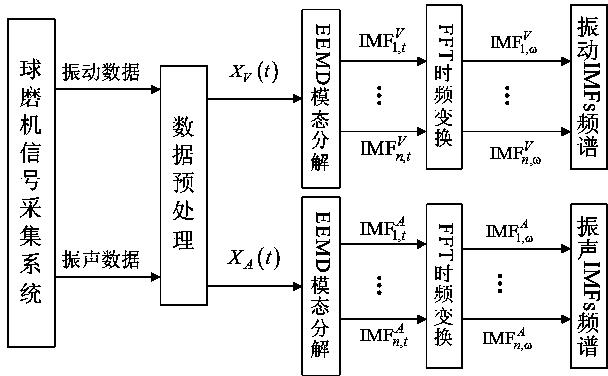

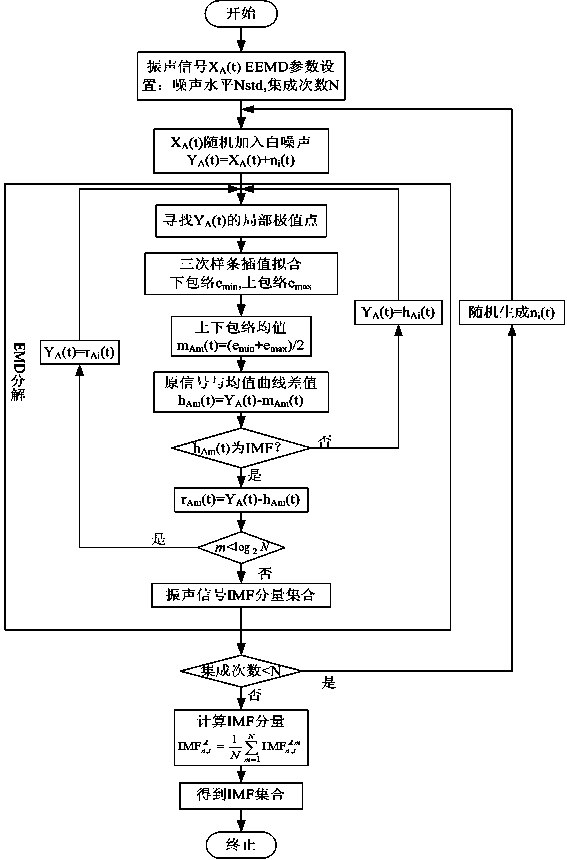

[0025] The present invention decomposes vibration and vibro-acoustic signals into a series of IMFs with different time scales through EEMD, and performs spectrum transformation, and then performs iPLS feature selection on the IMF spectrum to select the intrinsic mode function spectrum that is closely related to the load parameters of the mill The characteristic frequency band of the vibration characteristic spectrum, the vibration-acoustic characteristic spectrum and the current are fused together as the input of the multi-sensor information mill load parameter sub-model, and the mill load parameter soft Measure the submodels and integrate them. The regression of load parameters adopts the method of summing and averaging, and finally obtains the output result of the integrated model.

[0026] The present invention comprises following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com