A kind of preparation method of dynamic nickel cobalt lithium manganese oxide cathode material

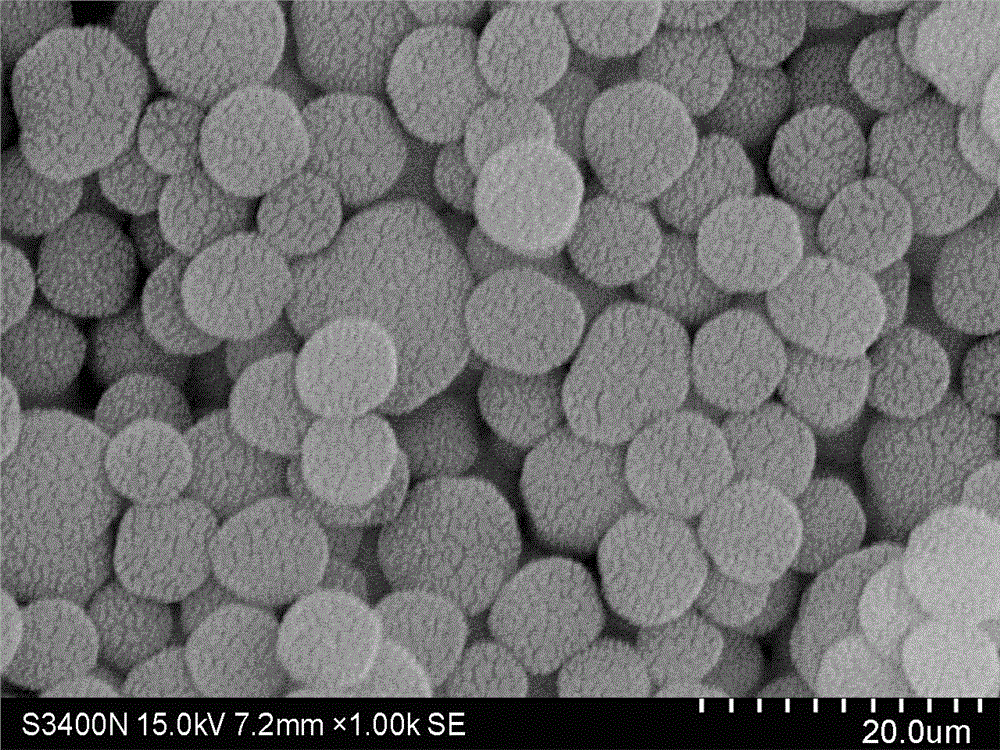

A technology of nickel-cobalt-lithium-manganese oxide and positive electrode materials, which is applied in the direction of chemical instruments and methods, battery electrodes, nickel compounds, etc., can solve the problem of difficult to obtain stable and stoichiometric coprecipitate, low electrochemical performance stability, water body and surrounding environmental pollution, to achieve the effects of optimizing material composition distribution, avoiding hydrolysis, and large tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of power type lithium cobalt manganese oxide comprises the following specific steps:

[0033] (1) Add lithium acetate, nickel acetate, cobalt acetate tetrahydrate, and manganese acetate according to the mass of 6.60g, 17.68g, 124.54g, and 69.2g, respectively, into dodecanoic acid with a volume of 2.2L at 50°C to dissolve, and stir for 2h Mix well, then add 2.2 g of triethylamine dropwise while stirring, and continue to stir for 3 hours to mix well to obtain solution I;

[0034] (2) Dissolve 59.39g of lithium acetate in 0.9L of water, add 1.8g of ethylene glycol, and stir for 1 hour to obtain solution II;

[0035] (3) Pressure spray granulation of solution I on nozzle A of the double-nozzle pyrolysis furnace, control the pressure at 0.6MPa, feed rate at 5000mL / h, and at the same time, carry out solution II on nozzle B of the double-nozzle pyrolysis furnace Pressure spray granulation, the control pressure is 0.3MPa, the feed rate is 2050mL / h;...

Embodiment 2

[0038] A kind of preparation method of power type lithium cobalt manganese oxide comprises the following specific steps:

[0039] (1) Add lithium acetate, nickel acetate, cobalt acetate tetrahydrate, and manganese acetate according to the mass of 6.60g, 17.68g, 124.54g, and 69.2g into tetradecanedioic acid with a volume of 1.5L at 135°C to dissolve, and stir Mix for 2 hours, then add 3.0 g of glyoxal dropwise while stirring, and continue stirring for 3 hours to obtain solution I;

[0040] (2) Dissolve 59.39g of lithium acetate in 0.6L of water, add 2.0g of glycerol, and stir for 1 hour to obtain solution II;

[0041] (3) Pressure spray granulation of solution I on nozzle A of the double-nozzle pyrolysis furnace, control the pressure at 0.5MPa, feed rate at 4000mL / h, and at the same time, carry out solution II on nozzle B of the double-nozzle pyrolysis furnace Pressure spray granulation, the control pressure is 0.2MPa, the feed rate is 1600mL / h; there is an adjustable baffle b...

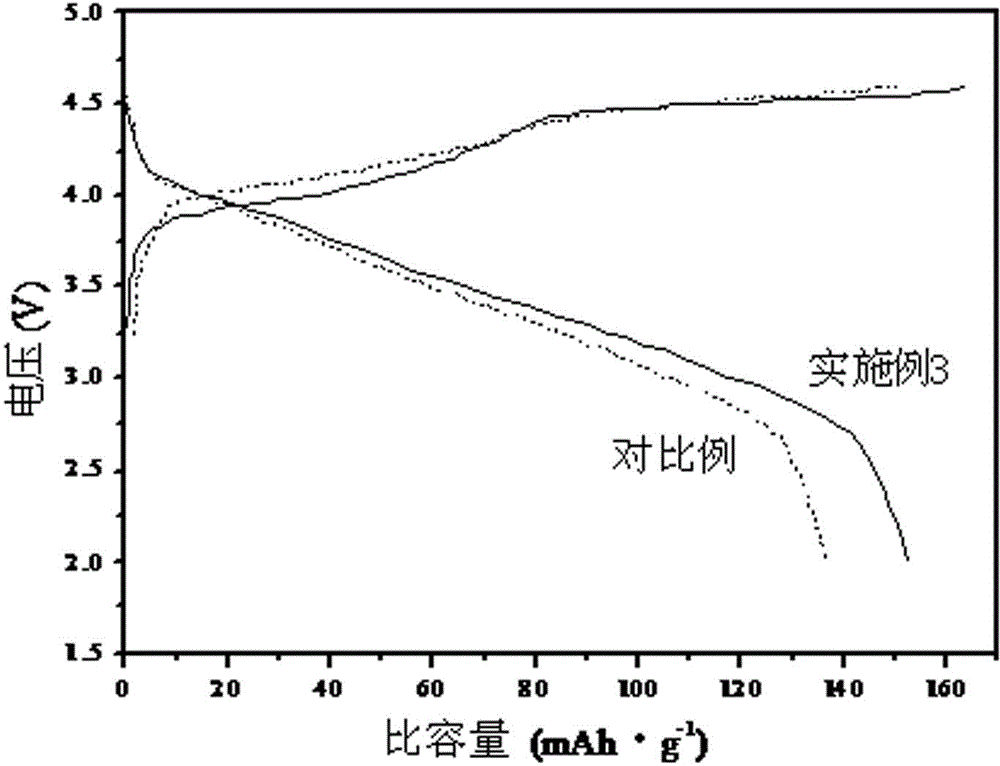

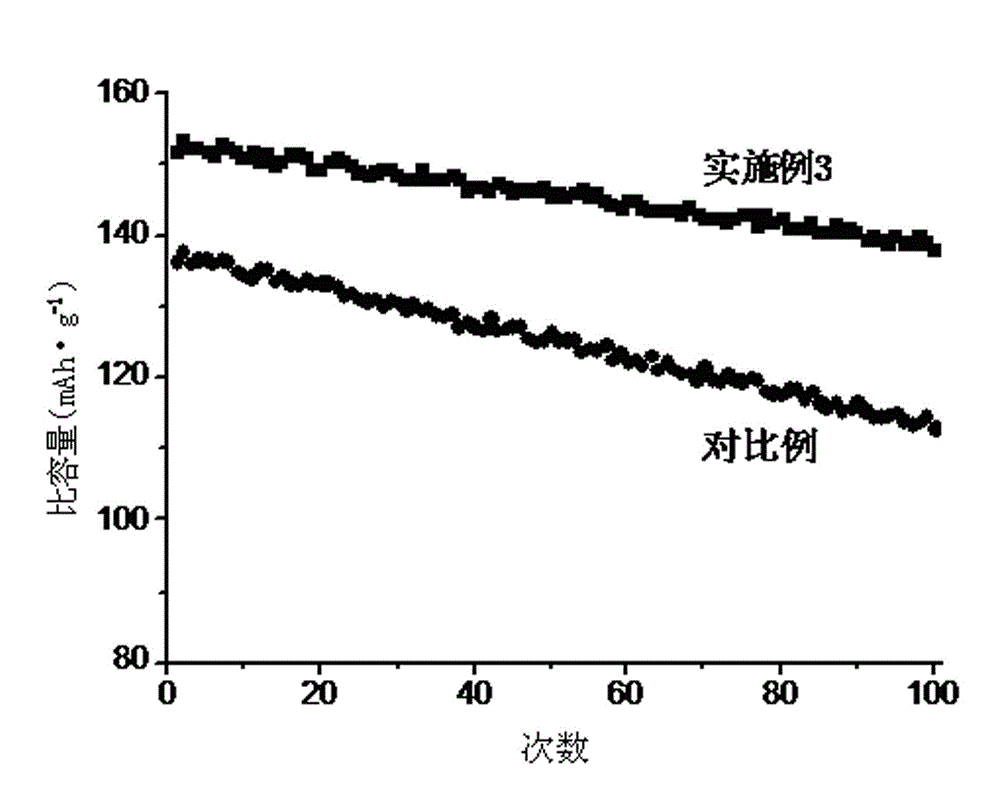

Embodiment 3

[0044] A kind of preparation method of power type lithium cobalt manganese oxide comprises the following specific steps:

[0045] (1) Add lithium oxalate, nickel oxalate, cobalt oxalate, and manganese oxalate according to the mass of 19.19g, 48.90g, 48.97g, and 47.65g to dissolve in 0.8L of hexadecanoic acid at 65°C, stir for 3 hours, and then Add 2.4 g of glutaraldehyde dropwise while stirring, and continue stirring for 2 hours to obtain solution I;

[0046] (2) Dissolve 76.78g of lithium oxalate in 0.267L of water, add 1.33g of triethanolamine, stir for 2 hours and mix well to obtain solution II;

[0047] (3) Pressure spray granulation of solution I on nozzle A of the double-nozzle pyrolysis furnace, control the pressure at 0.3MPa, and feed rate at 3000mL / h; at the same time, carry out solution II on nozzle B of the double-nozzle pyrolysis furnace Pressure spray granulation, the control pressure is 0.15MPa, the feed rate is 1000mL / h; the furnace is divided into drying secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap