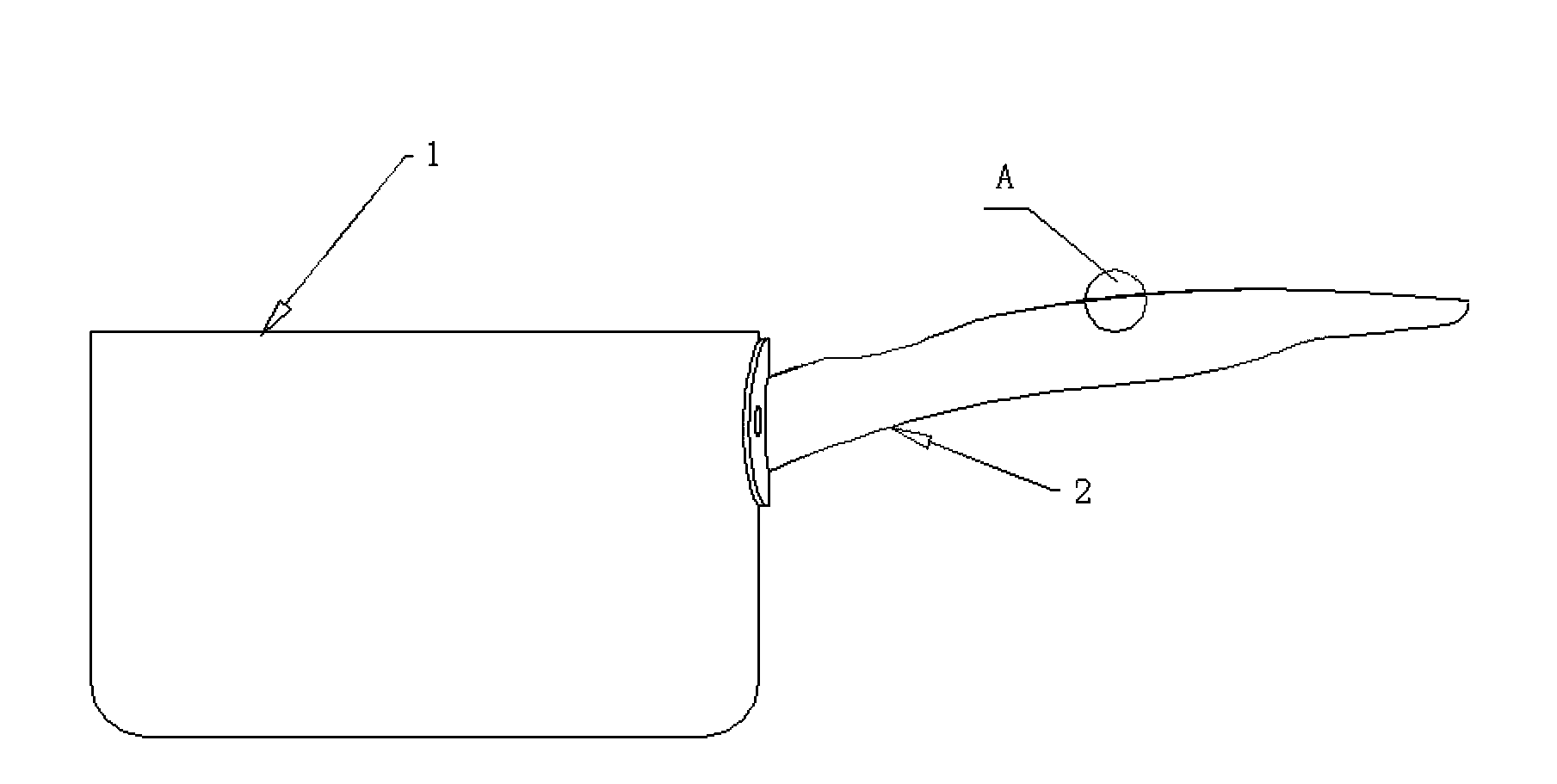

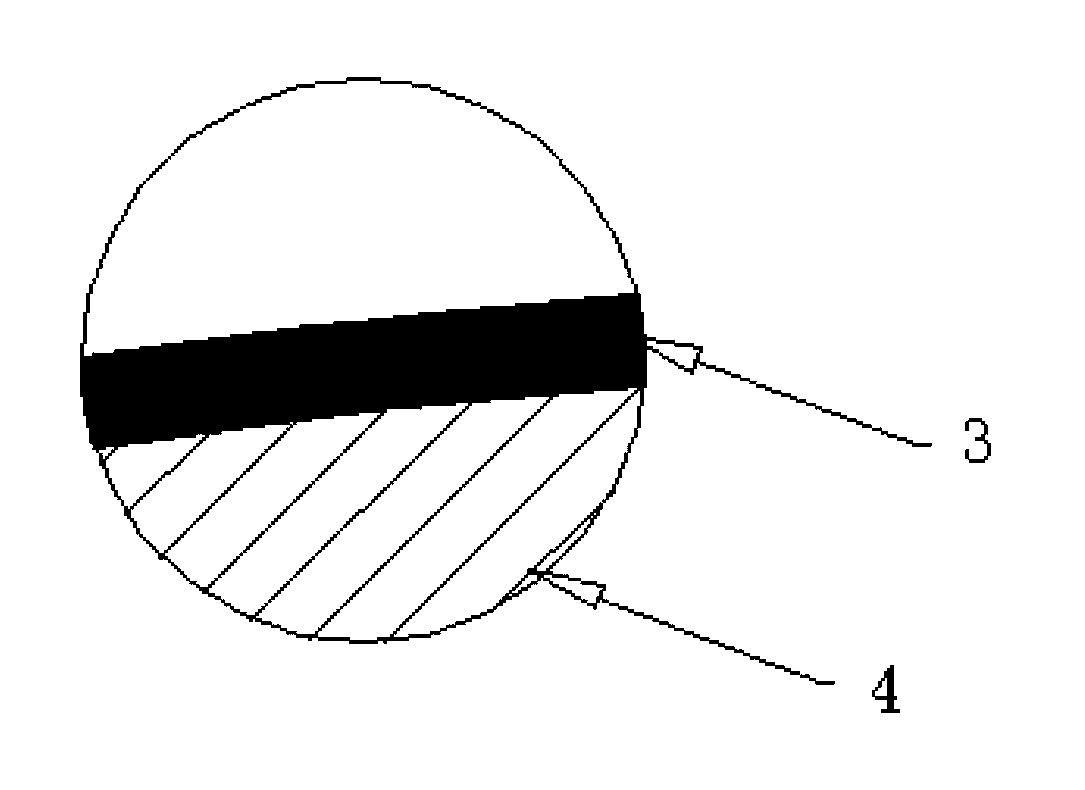

Heat-resistant cooker handle, preparation and application thereof

A technology for handles and cooking utensils, which is applied in heat-resistant cooking utensil handles and its preparation and application fields. It can solve the problems of thermal deformation temperature less than 250°C, resin and fiber peeling, cracking, etc., and achieve various colors, long service life, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0060] The preparation of embodiment 1-9 heat-resistant handle

[0061] A. Enamel glaze formula: Use the formula in Table 1 to prepare the bottom glaze and top glaze, and the modulation method is conventional.

[0062] Table 1 enamel formula (each raw material is in parts by weight)

[0063]

[0064]

[0065] *Half of the pigment used in Examples 1-9 is 6960, the other half is A-PAx-SA, and the prepared surface glaze is bright red.

[0066] *Inorganic silicate mineral composition used in the example:

[0067] Inorganic silicate mineral used in the embodiment, by weight percentage:

[0068]

[0069] In actual production, based on the source of inorganic silicate minerals and differences in batches, the ratio of each component will inevitably fluctuate. As long as the inorganic silicate minerals meet the following standards, they can replace the inorganic silicate minerals used in this example. For realizing the present invention.

[0070]

[0071] B, preparation...

Embodiment 10

[0087] Embodiment 10 Cookware handle performance test

[0088] 1. Temperature resistance test:

[0089] Heat resistance test according to European EM12983 standard: Make the oven reach the required temperature of 150+ / -5 degrees Celsius, put the test piece in the oven, let the oven return to the set temperature, turn on the timer, keep warm for 40mins, and take out the test piece , put it on a dry plane, visually test the sample (reference distance 250mm), and observe whether the sample has deformation, cracks and blisters.

[0090] Contrast: A. Bakelite and silicone handles: prone to blistering or deformation, accompanied by unpleasant odors.

[0091] B. Stainless steel handles: the surface will be oxidized and discolored.

[0092] C, the novel handle of embodiment 1-9: without any change, the surface also can not change color.

[0093] 2. Static load test:

[0094] Tested according to the European EM12983 standard, the strength of the handle must be able to support the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com