Vacuum pressure swing adsorption (VPSA) oxygen enrichment process

A technology of vacuum pressure swing adsorption and oxygen enrichment, which is applied in oxygen preparation, dispersed particle separation, chemical instruments and methods, etc. It can solve the problems of molecular sieve pulverization and uneven air distribution in the tower, so as to improve the adsorption performance and ensure the quality , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

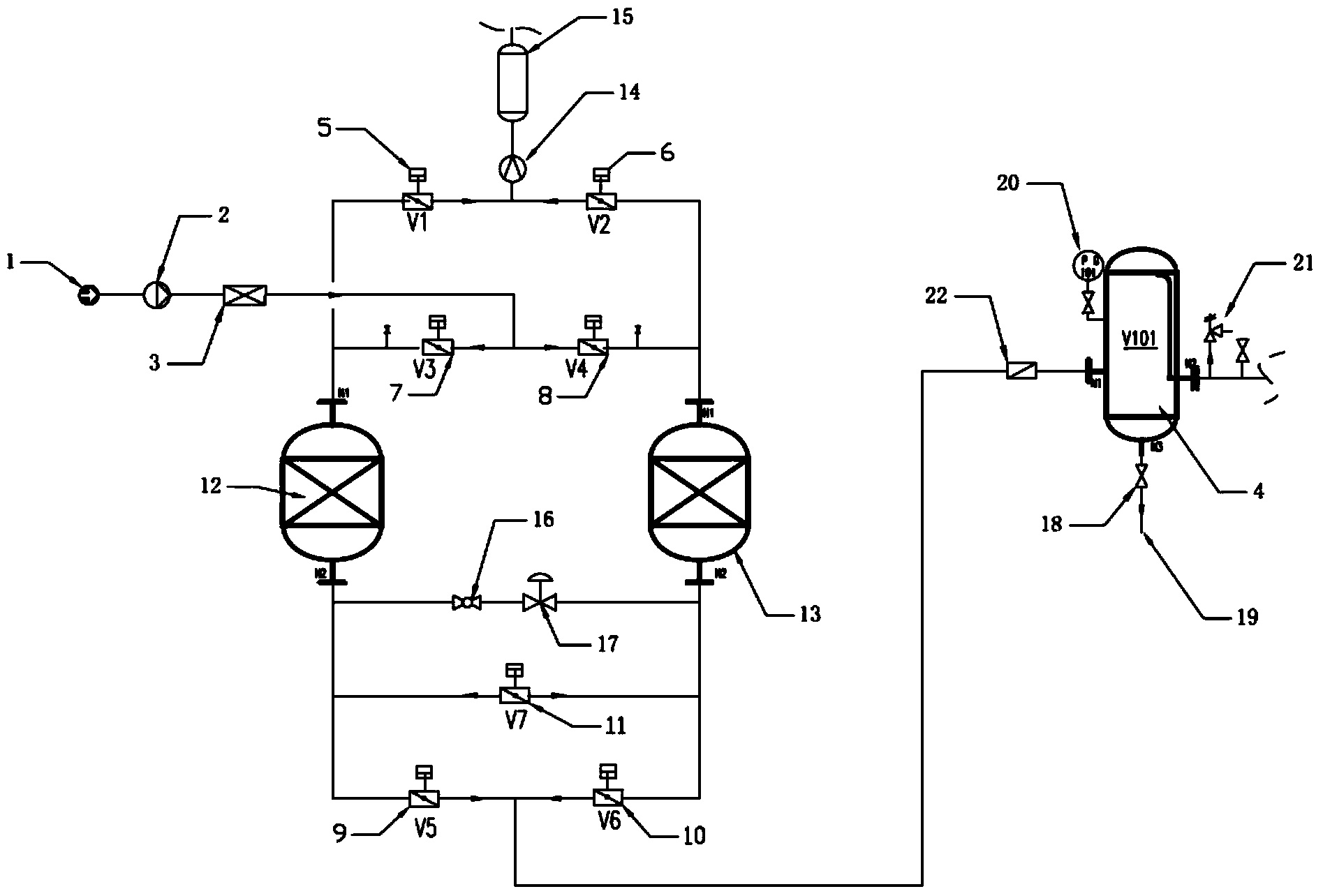

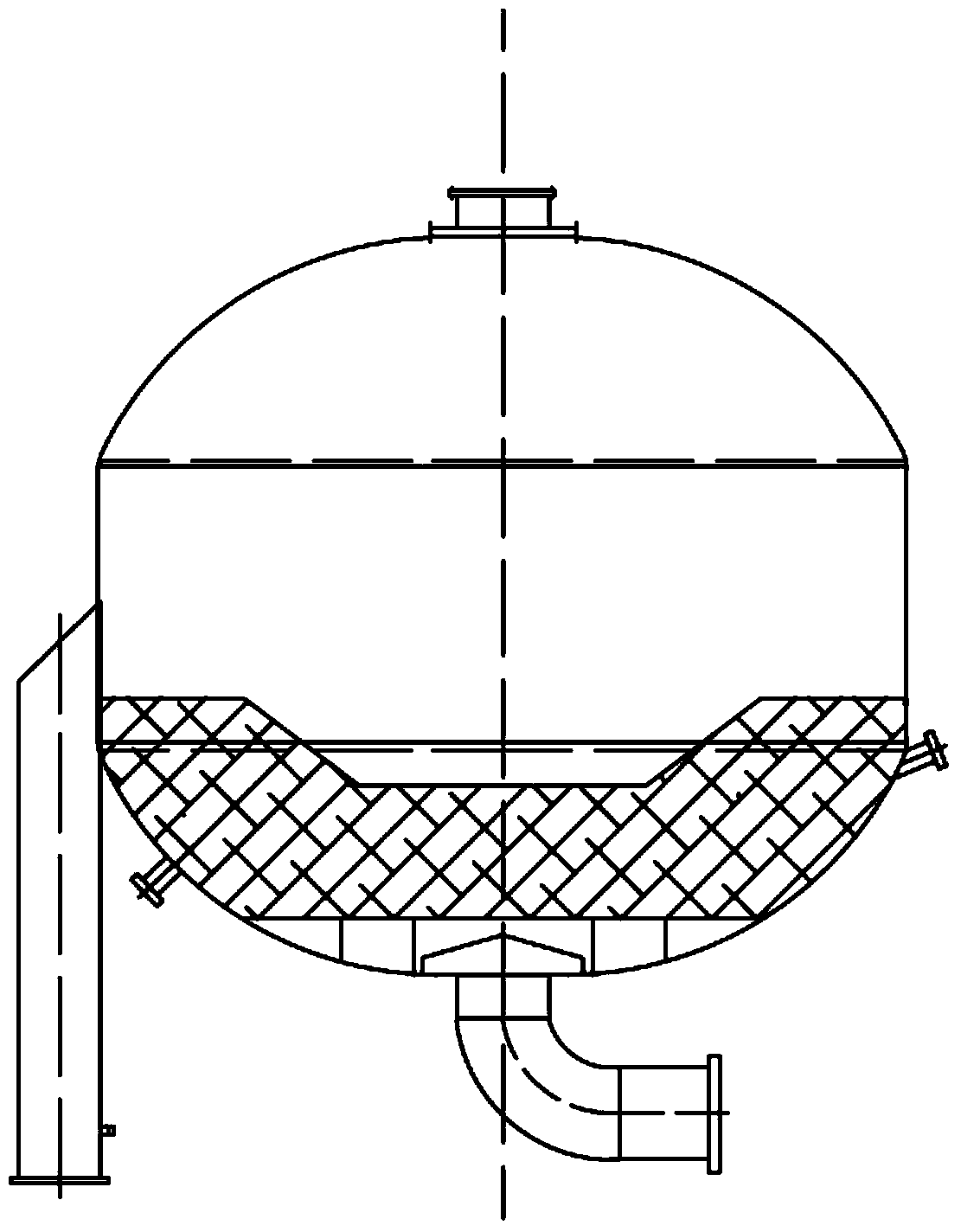

[0017] Example: such as figure 1 , a vacuum pressure swing adsorption oxygen-enrichment process, the outside air from the air inlet 1 through the blower 2, the heat exchanger 3, and then enters two adsorption towers that work alternately, the adsorption tower absorbs water and carbon dioxide in the air through the adsorbent , nitrogen and hydrocarbons, and the finished product oxygen enters the buffer tank 4, and its basic steps are adsorption, pressure release, vacuum desorption, pressure equalization, and pressure filling.

[0018] Specifically, when producing oxygen-enriched, the cycle step is adopted, the V3 air valve 7 is opened, the outside air passes through the blower 2 and the heat exchanger 3 from the air inlet 1, and then the air is fed from the upper end of the adsorption tower A12 through the blower 2 to pressurize Molecular sieves and activated alumina start to adsorb, and at the same time open the V2 gas valve 6, the vacuum pump 14 starts to work, and the adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com