Flat-type membrane filtration element and manufacturing method thereof, flat-type membrane filtration assembly and membrane bioreactor

A flat-plate membrane and filter element technology, applied in chemical instruments and methods, biological water/sewage treatment, membrane technology, etc., can solve problems such as low strength and low filtration efficiency, and achieve improved mechanical strength, high filtration efficiency, and improved The effect of filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

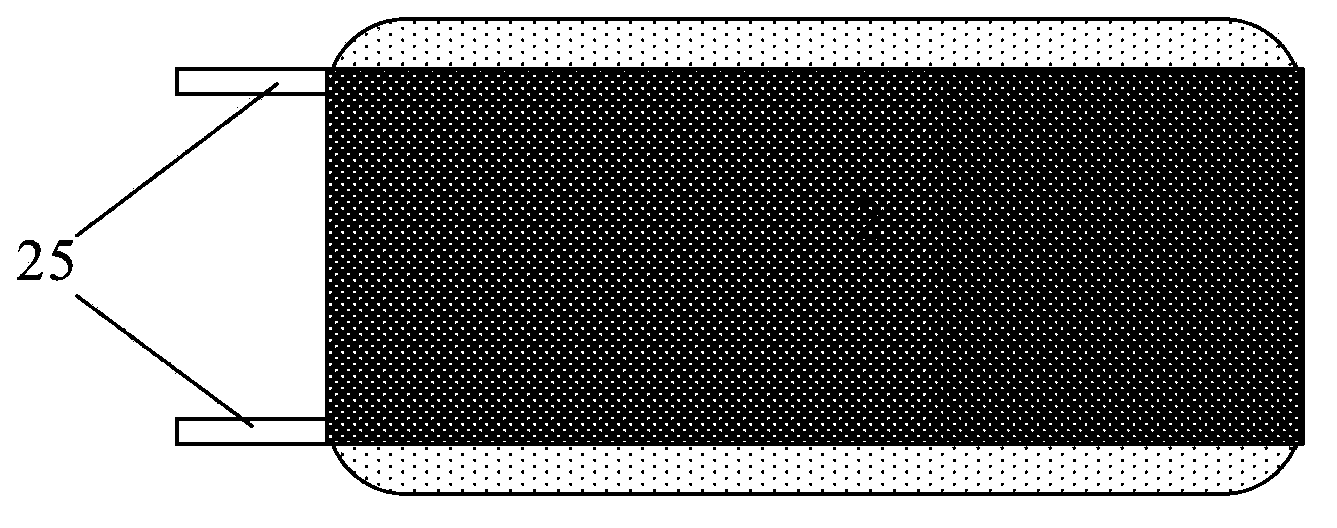

[0044] The following combination image 3 and Figure 4 , the structure of the flat-plate membrane filter element of the present invention will be described.

[0045] The present invention provides a flat-plate membrane filter element 2 , which has a membrane support 21 and a non-woven fabric membrane 22 . The membrane support 21 is in the shape of a flat plate, and the surface of the membrane support 21 has flow channels 24 distributed in a serpentine shape. The non-woven membranes 22 are respectively located on the surface of the membrane supports 21, and the non-woven membranes 22 are bonded to the membrane supports 21 by the edges around them to cover the serpentine distribution channels 24 on the membrane supports 21 on the non-woven membranes. Under the cloth membrane 22. There is a protruding structure 23 in the area where the surface of the membrane support 21 is covered by the non-woven membrane 22, and the protruding structure is used to prevent the non-woven memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com