Recycling system in thermosetting powder coating spray chamber

A powder coating, thermosetting technology, applied in the direction of coating, spraying device, device for coating liquid on the surface, etc., can solve the problems of affecting the recycling efficiency, increasing the recycling cost, easy damage to the filter element, etc., to achieve high recycling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and embodiments.

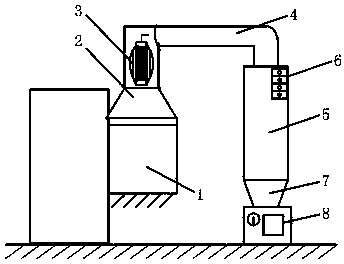

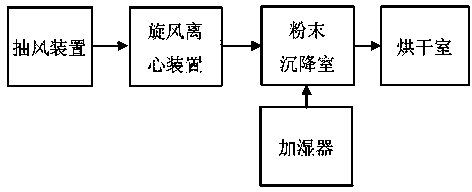

[0016] Such as figure 2 As shown, the exhaust fan 2 installed above or on the side of the spray chamber 1 draws the air floating with the powder coating into the recycling system, and uses the centrifugal effect of the cyclone centrifuge 3 to separate the powder from the air and pass it through the pipe 4. In the powder settling chamber 5, at the upper end of the powder settling chamber 5, one or more humidifiers 6 are installed to continuously spray water vapor to the gas and powder entering the chamber, so that the powder agglomerates and sinks to the bottom of the settling chamber, and then through The pipeline 7 enters the drying room 8 where it is heated and dried to obtain dry powder paint for reuse.

[0017] The exhaust fan 2 is installed above or on the side of the spray chamber 1 and has a trumpet shape and opens to the spray chamber to increase the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com