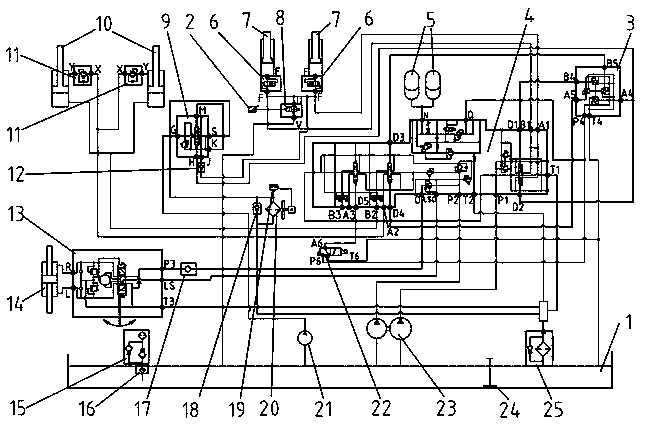

Hydraulic system of empty container stacking locomotive

A hydraulic system and container technology, applied in the field of hydraulic systems, can solve the problems of slow lifting speed of the mast, poor safety performance, inconvenient maintenance, etc., and achieve the effect of improving work safety, improving work efficiency, and reducing pipeline layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Such as figure 1 As shown, in the hydraulic system of an empty container stacker locomotive, the bottom of the fuel tank 1 is provided with a magnet 24, the upper part is equipped with a main return filter 25 and a fuel tank breather 15, and a block is installed below the fuel tank breather 15. The oil filter screen 16; the oil inlet ends of the gear pump 21 and the double gear pump 23 are all connected to the oil tank 1, and the two pump outlets of the double gear pump 23 are respectively connected to the P1 and P2 ports on the integrated multi-way valve 4. The outlet of the gear pump 21 is connected to the G port on the quick-lift valve group 9. The LSO port on the integrated multi-way valve 4 is connected to the LS port of the steering gear 13, the O port on the integrated multi-way valve 4 is connected to the P3 port of the steering gear 13 through the one-way valve 17, and the T3 port on the steering gear 13 passes through the main The oil return filter 25 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com