Bottle glass formula

A glass and formula technology, applied in the field of low-magnesium, low-alkali and high-calcium bottle glass formula, can solve the problems of reducing glass viscosity, shortening glass frit, and large content, so as to improve water resistance, improve forming performance, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

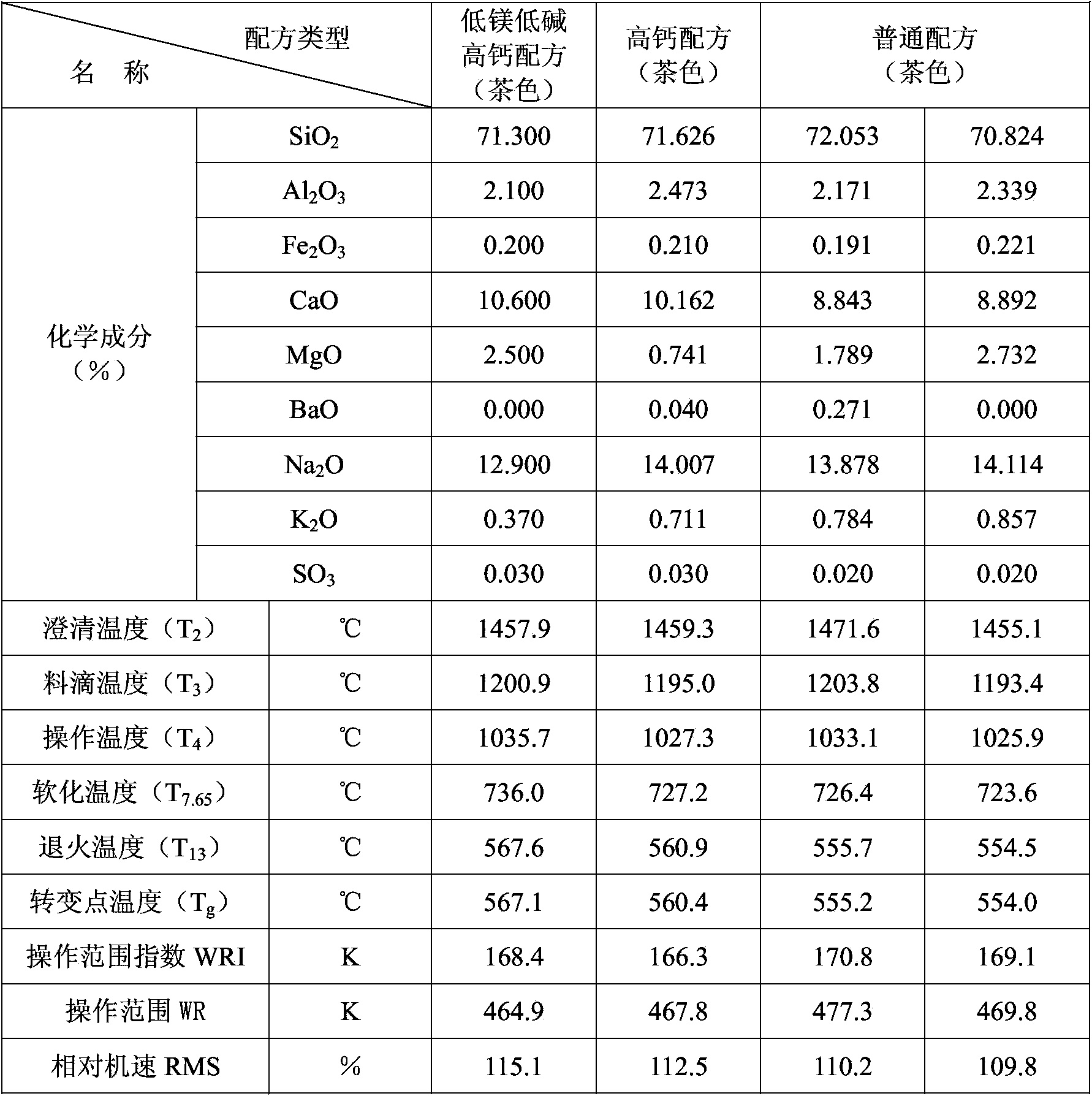

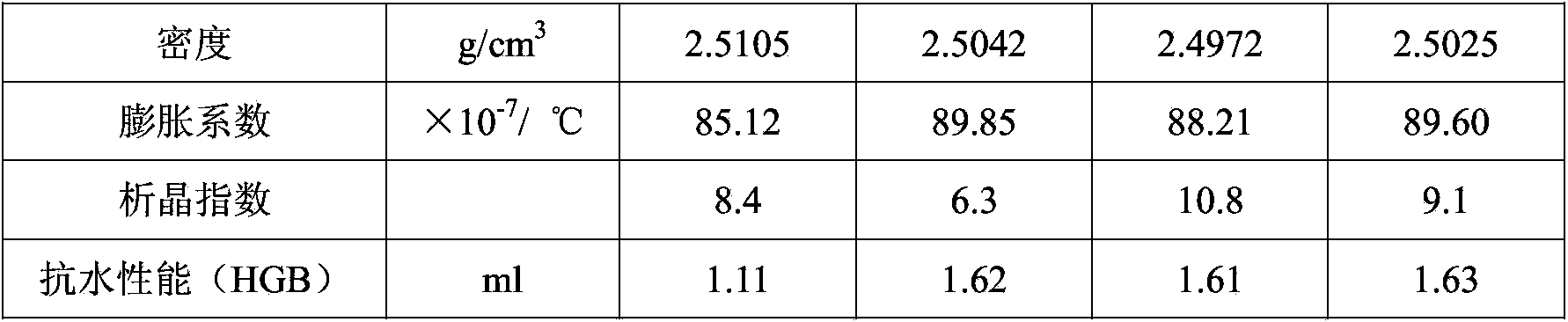

[0012] Table 1: Chemical composition and viscosity-temperature characteristic data of low-magnesium, low-alkali, high-calcium, high-calcium and common formulations

[0013]

[0014]

[0015] in:

[0016] 1. The operating range (WR) is equivalent to the temperature range of the glass liquid surface during forming;

[0017] 2. The operating range index (WRI) is an indicative number of the operating (forming) range, which can represent the length of the material;

[0018] 3. Crystallization index: Positive number means no crystallization, negative number means crystallization potential.

[0019] 4. The relative machine speed (RMS) reflects the forming characteristics of different glasses. It is expressed as a percentage. It is relative and can be compared, but cannot be used for the calculation of absolute numbers.

[0020] Introduce Na 2 The raw material of O is soda ash. Soda ash is a chemical raw material, the price is relatively expensive, and it has a great impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com