Heat-transfer heat-accumulation medium prepared by combining quartz sand and ternary molten nitrate salt and preparation method thereof

A heat storage medium and quartz sand technology, applied in chemical instruments and methods, heat exchange materials, energy input, etc., can solve the problem of low upper limit temperature of ternary nitric acid molten salt, and achieve improved thermal stability and upper limit The effect of using temperature, high energy utilization rate and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

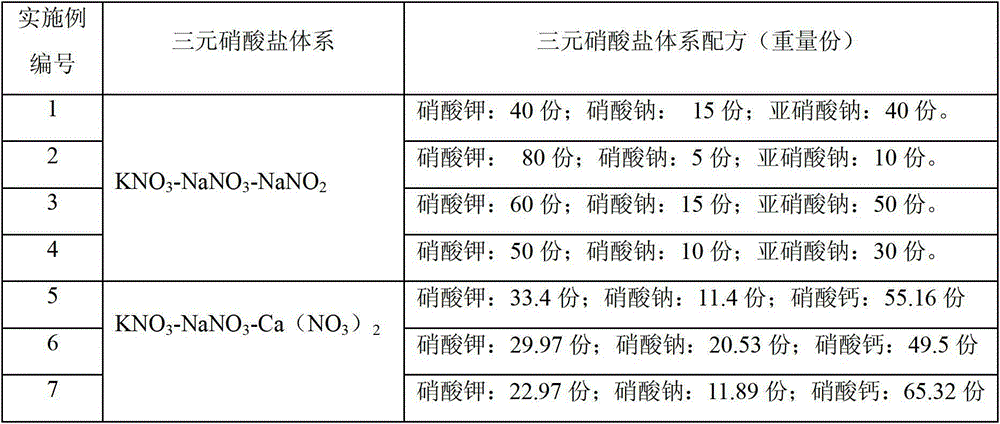

[0032] Embodiment 1~4. Ternary nitrate system KNO 3 -NaNO 3 -NaNO 2 Preparation of heat storage and heat transfer medium by adding quartz sand

[0033] Step 1. Prepare the materials that form the ternary nitric acid molten salt system according to the formula listed in Table 1, put it into the reaction kettle, heat and stir to melt the solid completely, then keep the temperature for 0.5-1h, and the heating temperature is 50 °C above the molten salt phase transition temperature. -100℃.

[0034] Step 2. Under stirring conditions, disperse the quartz sand into the molten ternary nitric acid molten salt system, continue stirring for 1-2 hours, and the mixture is gelatinous.

[0035] Step 3. Cool and pack.

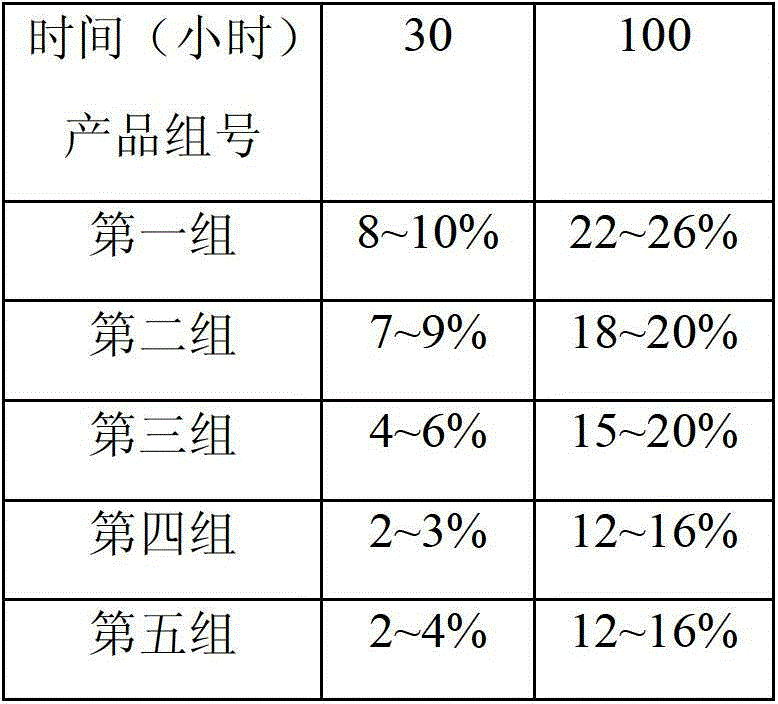

[0036] The added quartz sand (specification is 100 mesh) is carried out in a gradient as follows:

[0037] The first group: quartz sand accounts for 1% of the four kinds of quartz sand composite ternary nitric acid molten salt heat transfer and heat storage medium, and the...

Embodiment 5~7 3

[0055] Embodiment 5~7 ternary nitrate system KNO 3 -NaNO 3 -Ca (NO 3 ) by adding quartz sand to prepare heat storage and heat transfer medium

[0056] The quartz sand composite ternary nitric acid molten salt is prepared according to the formula listed in Table 1, and the method is the same as that of the steps 1 of Examples 1 to 4.

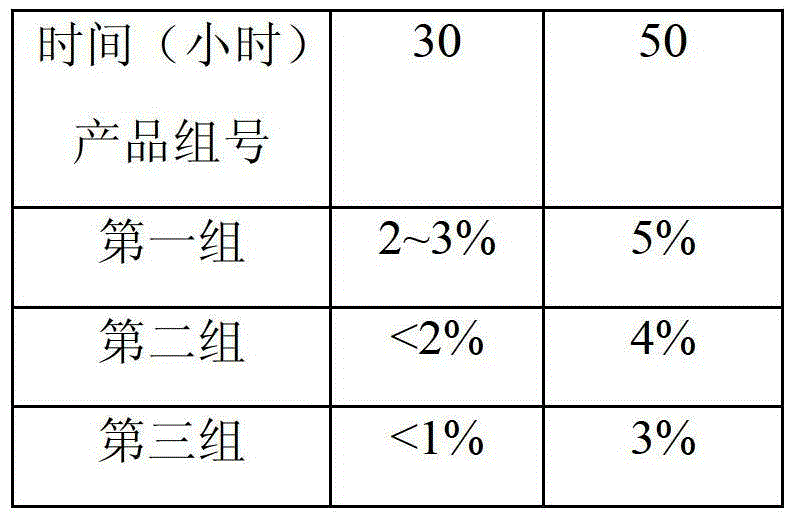

[0057] The addition of quartz sand proceeds in a gradient:

[0058] The first group: quartz sand accounts for 1% of the three kinds of quartz sand composite ternary nitric acid molten salt heat transfer and heat storage medium, and the 17th to 19th products are obtained.

[0059] The second group: quartz sand accounts for 30% of the four kinds of quartz sand composite ternary nitric acid molten salt heat transfer and heat storage medium, and the 20th to 22nd products are obtained.

[0060] The third group: quartz sand accounts for 50% of the four kinds of quartz sand composite ternary nitric acid molten salt heat transfer and heat storage med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com