Water temperature control circulating cooling system for diffusion pump of vacuum coating machine

A circulating cooling system and vacuum coating machine technology, applied in the electronic field, can solve the problems of wasting emergency water, failing to guarantee the safety threshold of the cooling system, and damaging the vacuum coating equipment, so as to avoid waste, realize linkage automatic control, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the accompanying drawings.

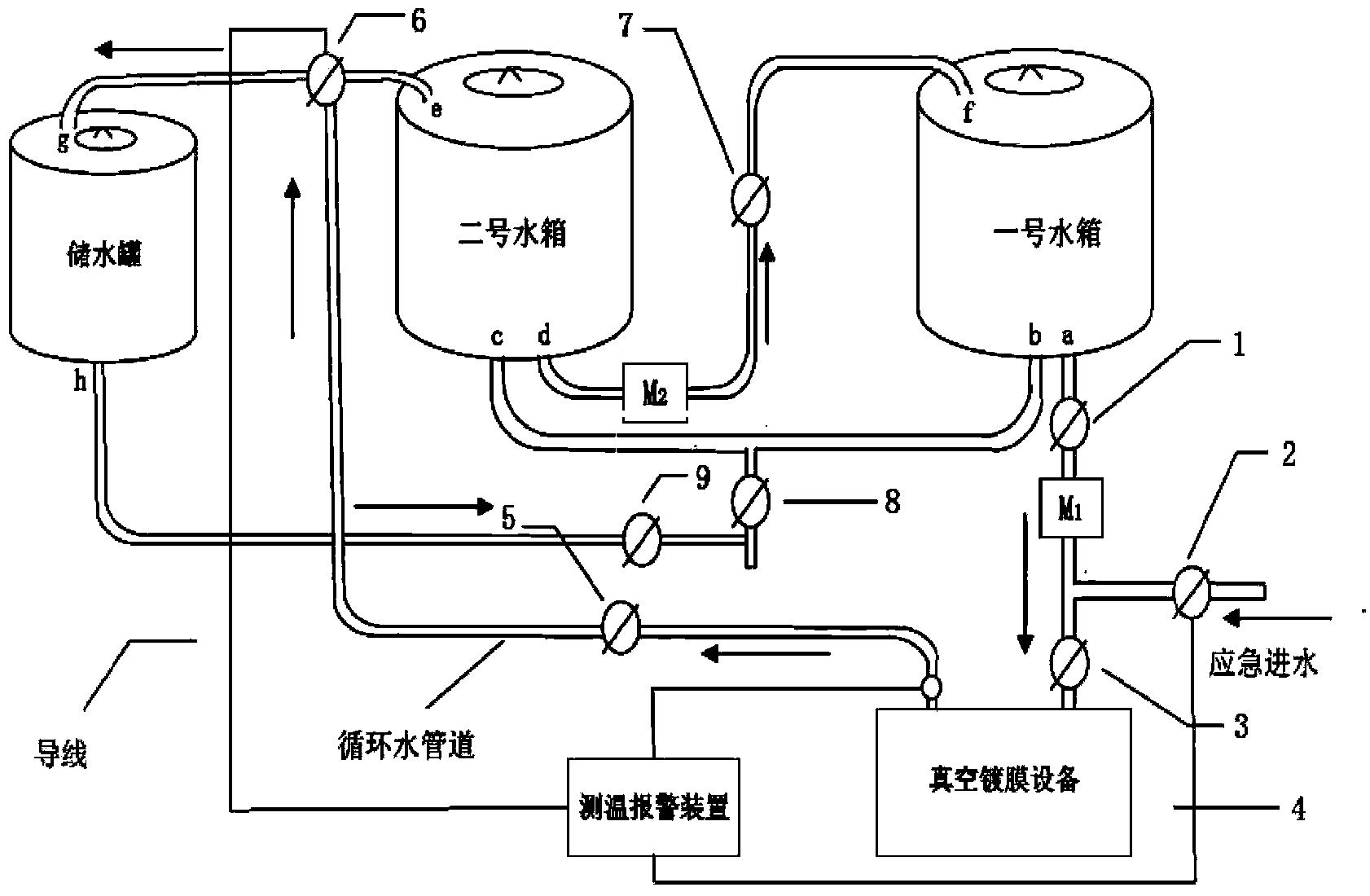

[0018] refer to figure 1 , the circulating cooling water system of the present invention is mainly composed of two water storage tanks, a water storage tank, five water valves, two electromagnetic valves, two water pumps, vacuum coating equipment and a temperature measurement and alarm device. Connect as follows.

[0019] The water outlet pipe a at the bottom of the No. 1 water tank passes through the water valve 1 and the water pump M in turn. 1 , The water valve 3 is connected with the water inlet pipeline of the vacuum coating equipment 4 to form the cooling water inlet pipeline of the vacuum coating equipment 4 . water pump M 1 The right-angle end of the three-way interface between the water valve 3 is connected with the tap water port through the manual electromagnetic water valve 2 to form an emergency water inlet. The water outlet pipe b at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com