Tire-gravel drainage pile composite foundation treatment method

A composite foundation and treatment method technology, applied in the field of tire-gravel drainage pile composite foundation treatment, can solve the problem of soil around the pile weakening the radial restraint effect of the soil body, limited ability of the soil around the pile to resist horizontal displacement, black pollution, etc. problems, to achieve good drainage consolidation effect, improved mechanical and deformation coordination, and small pile settlement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

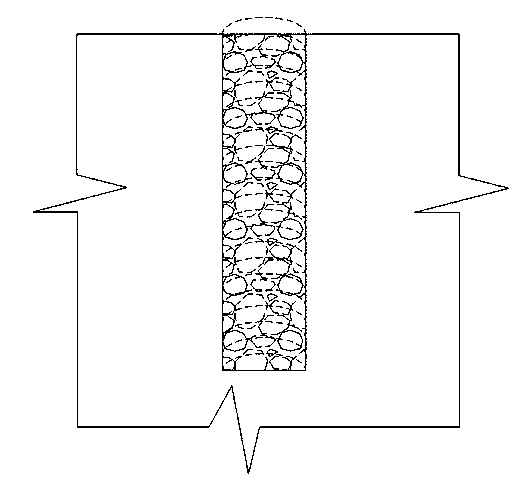

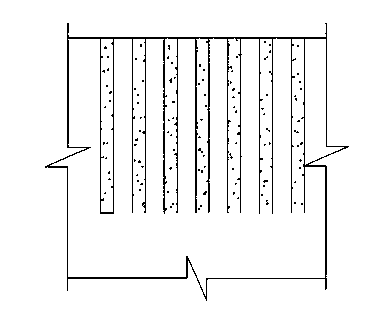

[0042] Below in conjunction with accompanying drawing and example 1, the present invention will be further described:

[0043] The tire-gravel drainage pile composite foundation treatment method includes the following steps:

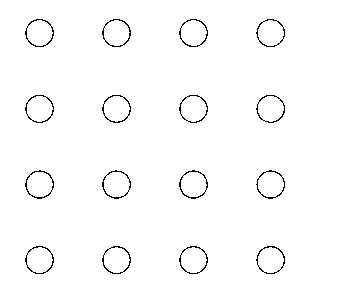

[0044] Step 1 Determine the relevant parameters, including the reinforcement range of the foundation, the layout of the piles, the distance between the tire gravel piles, the reinforcement depth of the composite foundation of the tire gravel piles, the diameter of the piles, the amount of filler in the pile holes, and the gravel at the top of the sand gravel piles The thickness of the underlayment.

[0045] Step 2 Carry out construction according to the parameters obtained in step 1:

[0046] At the position where the pile body is set, the casing is fixed with a guide frame; the length of the casing is 1.15 times the design depth of the pile body, and the casing is driven into the soil to the predetermined design depth; the drainage hole is prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com