Liquid crystal display with anti-static structure and manufacturing method thereof

A technology of liquid crystal display and manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., and can solve the problems of increasing the conductive film and decreasing the transmittance of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

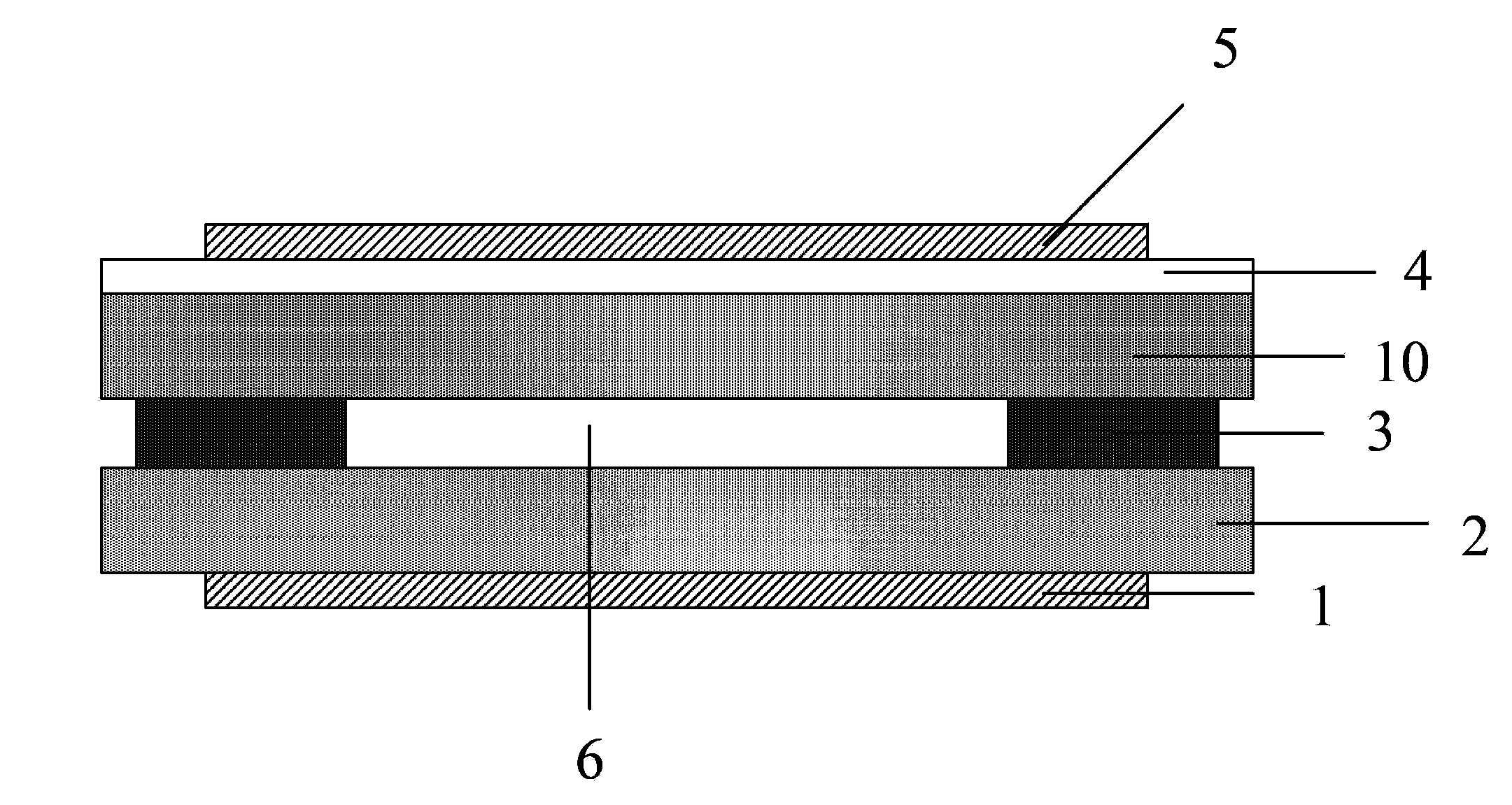

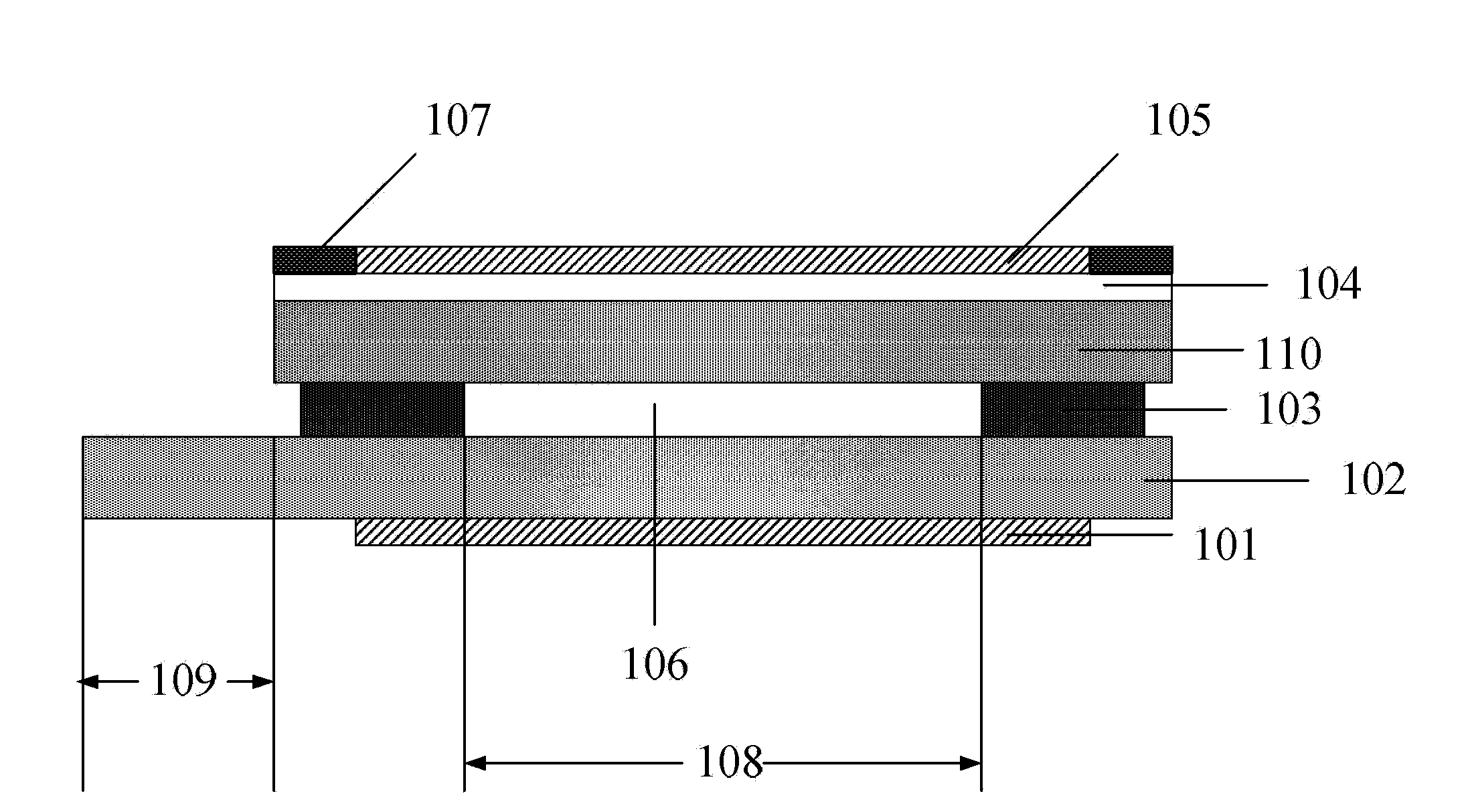

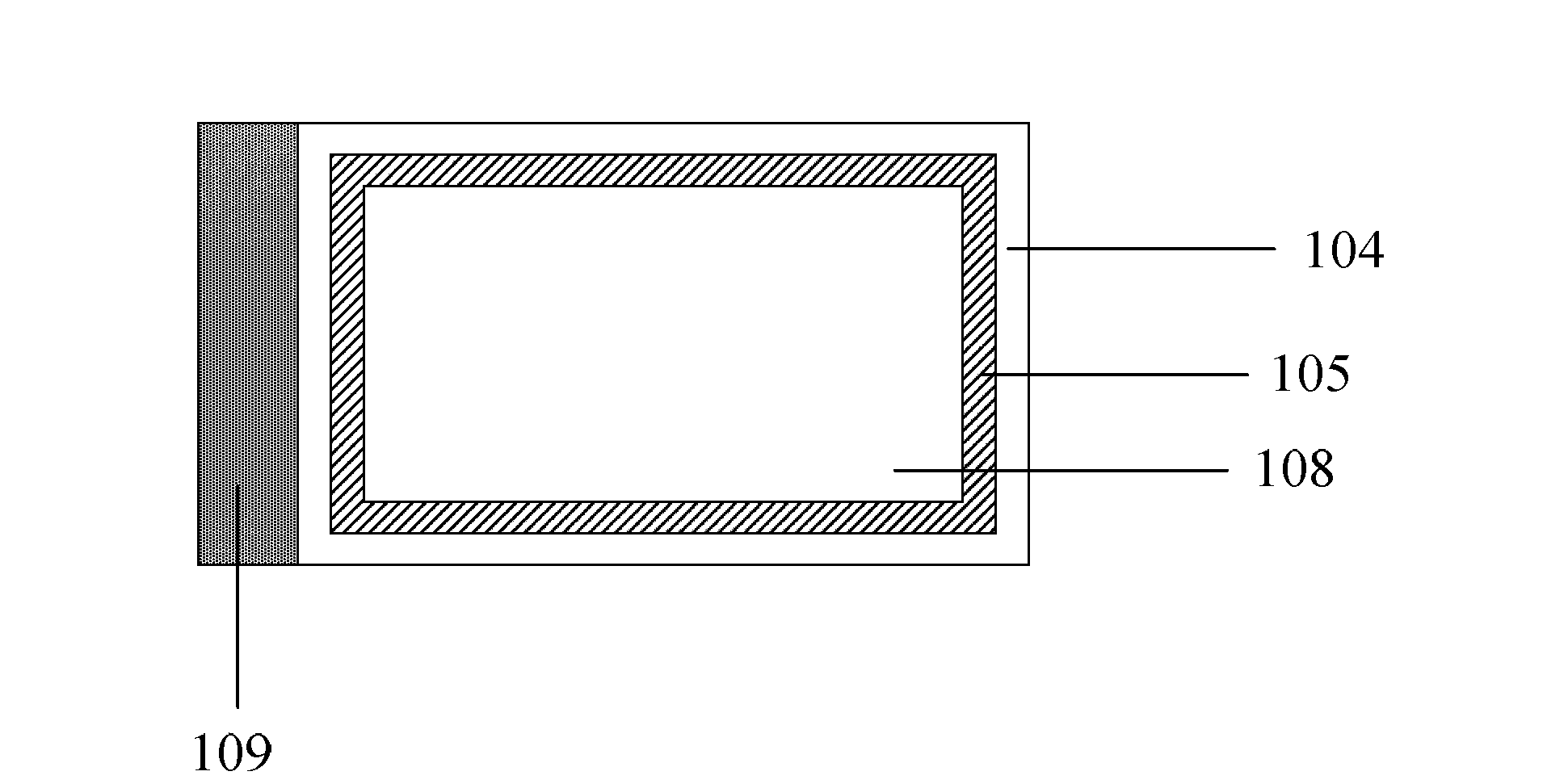

[0060] This embodiment provides a liquid crystal display with an antistatic structure, figure 2 A schematic diagram of the structure of the liquid crystal display. Such as figure 2 As shown, the liquid crystal display includes a color filter substrate 110 and an array substrate 102 arranged parallel to and corresponding to each other on the upper and lower sides, a liquid crystal layer 106 and a sealant 103 sandwiched between the color filter substrate 110 and the array substrate 102, the liquid crystal display Active display area 108 is included. There is a lower polarizer 101 under the array substrate, an upper polarizer 105 is arranged on the color filter substrate 110, and a first conductive film 104 is arranged between the upper polarizer 105 and the color filter substrate 110, and the first conductive film 104 It completely covers the color filter substrate 110 for electrostatic protection and electric field shielding. However, the first conductive film will reduce ...

specific Embodiment 2

[0074] This embodiment provides another liquid crystal display with an antistatic structure, image 3 A schematic diagram of the structure of the liquid crystal display. Such as Figure 4 As shown, the liquid crystal display includes a color filter substrate 210 and an array substrate 202 arranged parallel to each other on the upper and lower sides, a liquid crystal molecular layer 206 and a sealant 203 sandwiched between the color filter substrate 210 and the array substrate 202, and the liquid crystal The molecular layer 206 forms the active display area 208 of the liquid crystal display.

[0075] There is a lower polarizer 201 under the array substrate, an upper polarizer 205 is arranged on the color filter substrate 210, and a layer of first conductive film 204 is provided between the upper polarizer 105 and the color filter substrate 210. The first conductive film 204 It completely covers the color filter substrate 210 for electrostatic protection and electric field shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com