Lithium ion battery end cover, lithium ion battery and production method of lithium ion battery

A lithium-ion battery and end cap technology, applied in the field of batteries and rechargeable batteries, can solve the problems of small contact area, poor sealing, cracked batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

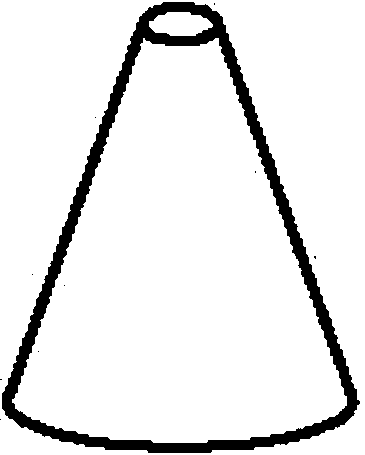

[0036] Depend on figure 1 , figure 2 It can be seen that a lithium-ion battery end cover includes a cover body 1, a positive and negative electrode guide pin 2 whose tail is located in the cover body 1, and the tails of the positive and negative electrode guide pins 2 are each provided with a stopper to prevent the guide pin 2 from coming out of the cover body 1. The guide needle holder 3, the guide needle holder 3 at the tail of the positive and negative pole guide needles 2 is integrally injected into the cover body 1, and the guide needle holder 3 is a conductor, and the bottom of the guide needle holder 3 is flush with the bottom of the cover body 1, so that Connect the battery tabs.

[0037] The cover body 1 of the present invention can be made of polycarbonate (PC) or AS styrene-acrylonitrile copolymer or polyethylene (PE) by injection molding (the styrene-acrylonitrile copolymer used in this embodiment).

[0038] The guide pin 2 and the guide pin seat 3 of the presen...

Embodiment 2

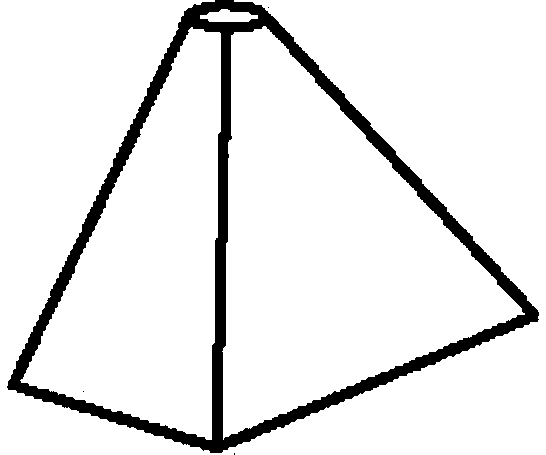

[0042] Depend on figure 1 , image 3 It can be seen that the guide needle holder 3 in this embodiment is in the shape of a pyramid.

[0043] The rest are the same as embodiment 1.

Embodiment 3

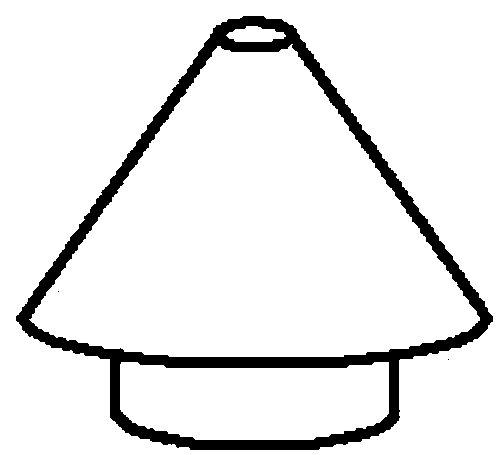

[0045] Depend on Figure 4 , Figure 5It can be seen that, in order to prevent the guide pin 2 from falling out in the present invention, the guide needle holder 3 described in this embodiment includes a fall-off prevention cone 31, a connection base 32 located below the fall-off prevention cone 31, and the bottom of the connection base 32 and the cover 1. The bottom is flush, the anti-off cone 31 is conical or pyramid-shaped, and the connecting base 32 is cylindrical or prism-shaped; the bottom surface area of the anti-off cone 31 is greater than the cross-sectional area of the connecting base 32 (the present embodiment The middle anti-off cone head 31 is a cone shape, and the connecting base 32 is a cylinder shape).

[0046] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com