Composite vibration film

A composite, central technology, applied in the field of loudspeakers, can solve the problems of affecting the energy dissipation of the diaphragm, unable to provide high-definition sound quality, and the limitation of the ductility of the diaphragm, and achieve high hardness, large elastic deformation, and good ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

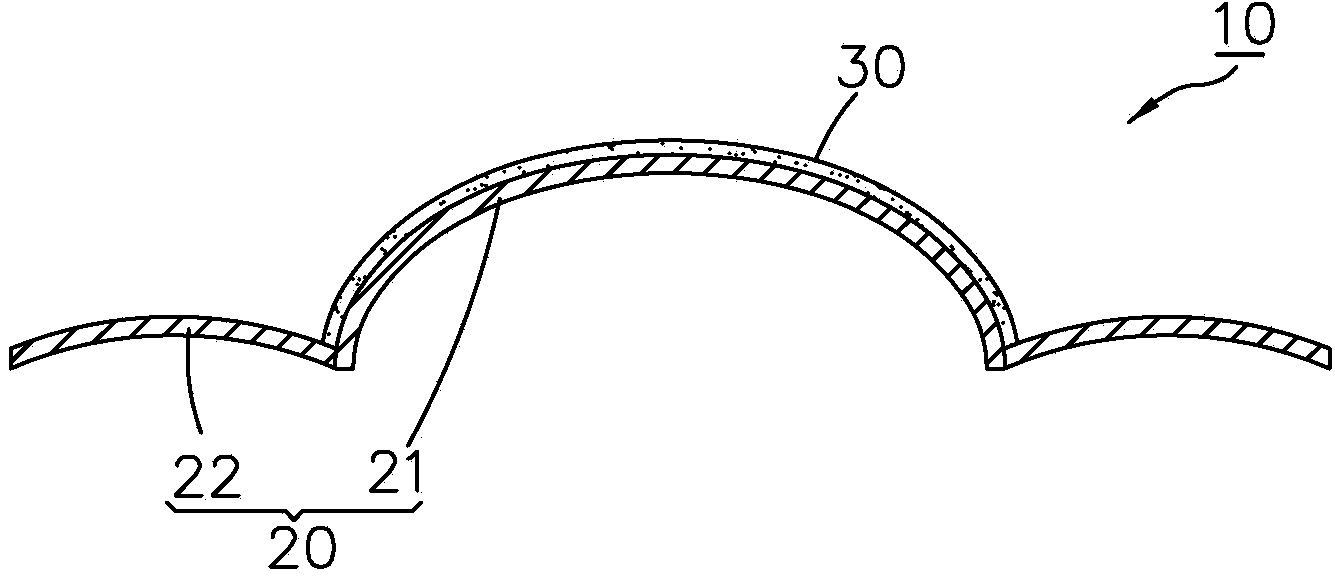

[0022] Embodiment one: see attached figure 1 As shown, a composite diaphragm 10 includes a substrate 20 and a micro-nano ceramic layer 30 .

[0023] The material used for the base material 20 can be selected from one of metal, polymer material, cloth, silk, hemp, paper or composite material, and is not particularly limited here. In this embodiment, the substrate 20 has a central portion 21 and an edge portion 22 , the edge portion 22 is disposed on the outer periphery of the central portion 21 , and the cross-sectional shapes of the central portion 21 and the edge portion 22 are arc-shaped.

[0024] The micro-nano ceramic layer 30 is defined here as a ceramic material in the form of micro-nano crystals with at least one dimension smaller than 500 microns in zero-dimensional, one-dimensional, two-dimensional or three-dimensional (corresponding to points, lines, planes, and three-dimensional) scales It is made, and the micronano referred to here refers to the nanometer s...

Embodiment 2

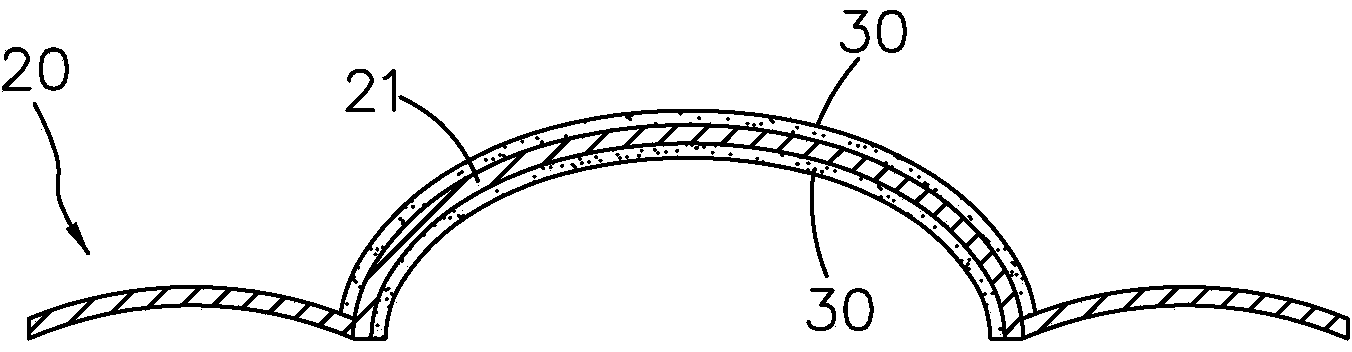

[0025] Embodiment two: see attached figure 2 As shown, the present embodiment is basically the same as the first embodiment, except that the number of micro-nano ceramic layers 30 is two layers and is arranged on the upper and lower surfaces of the central portion 21 .

Embodiment 3

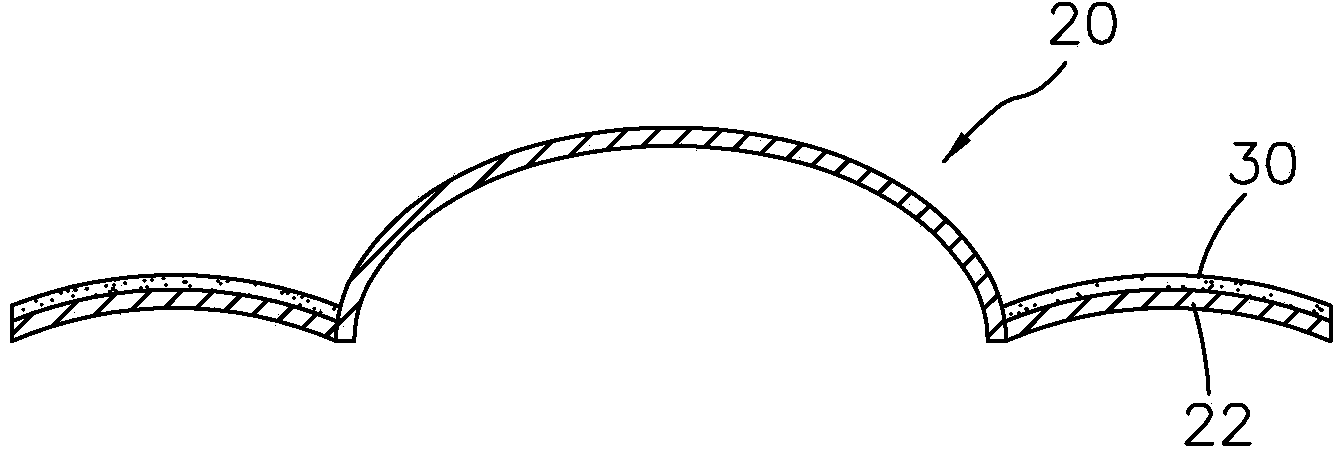

[0026] Embodiment three: see attached figure 2 As shown, this embodiment is basically the same as the first embodiment, except that the micro-nano ceramic layer 30 is disposed on the upper surface of the edge portion 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com