Producing technology for processing raw material seeds by corn seeds

A technology for processing raw materials and production technology, which is applied in the field of corn seed processing raw material seed production technology, can solve the problems of low labor efficiency, reduced vitality of raw material seeds, large investment in ear drying facilities, etc., and achieves the effect of wide application and effective supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

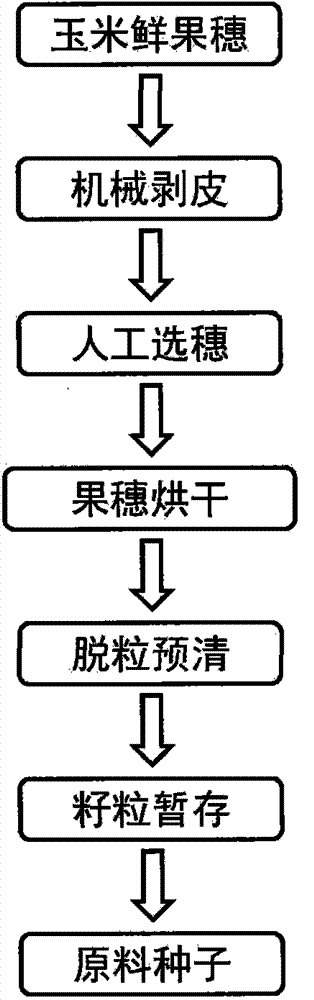

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0008] Such as figure 1 As shown, the present invention is based on the drying and dehydration characteristics of corn ears, adopts a variable temperature drying process to perform efficient and safe dehydration of corn ears, improves production efficiency and ensures the quality of raw material seeds, and realizes effective supply of raw material seeds. The corn seed processing raw material seed production process involved in the present invention includes mechanical peeling, manual ear selection, ear drying, threshing pre-clearing, and grain temporary storage procedures. The specific implementation methods are as follows:

[0009] (1) Mechanical peeling: The fresh corn ears harvested manually or mechanically are transported to the seed processing plant for centralized processing, and the corn peeling machine is used to peel the fresh corn ears with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com