Wet-type dense grid filter purifier

A technology of dense grids and purifiers, applied in gravity filters, loose filter material filters, filtration and separation, etc., can solve the problems of single fiber grids that reduce purification efficiency, aerosol particles are easy to leak, and affect the cleaning of cleaning fluids, etc. , to achieve the effect of improving filtration and purification efficiency, increasing service life, and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

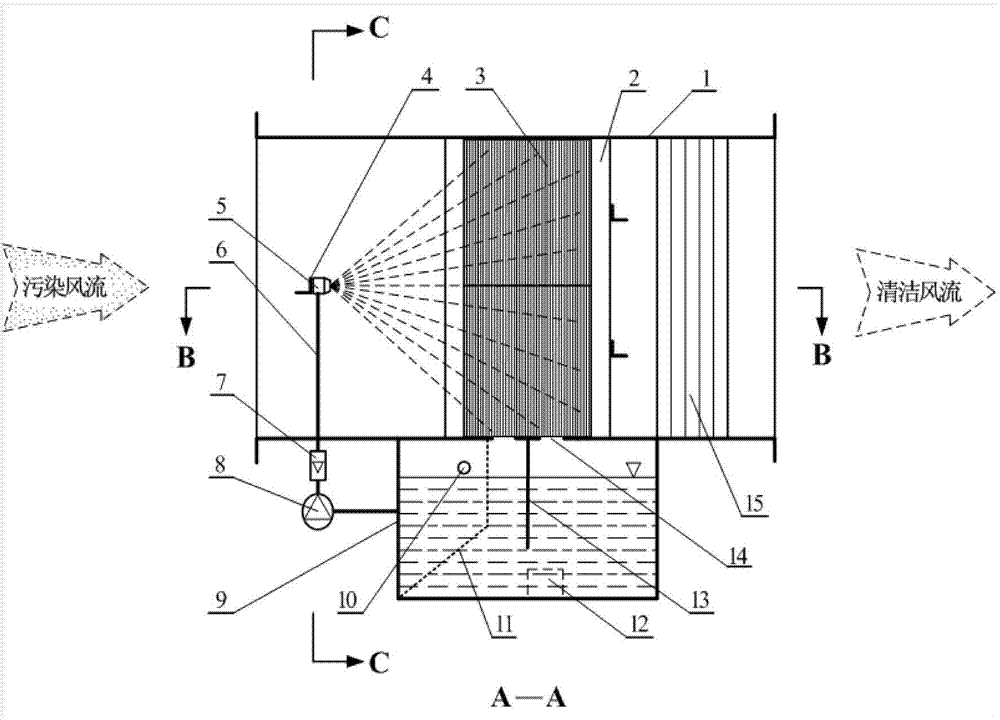

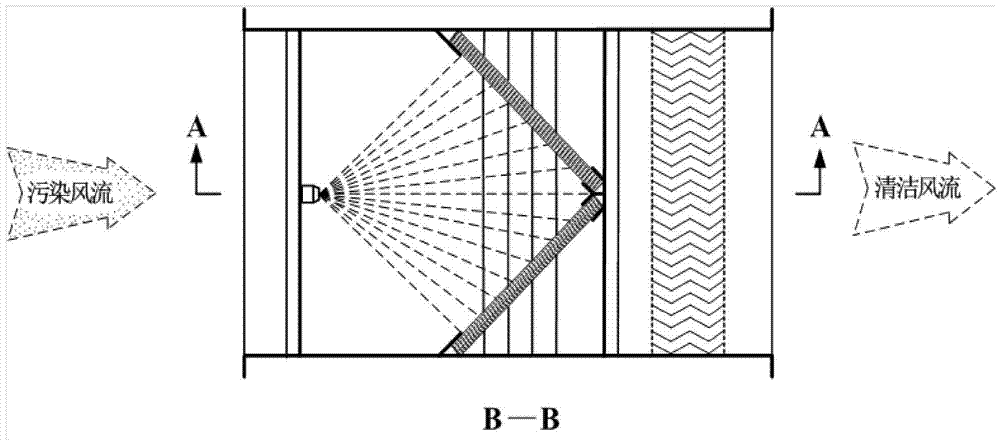

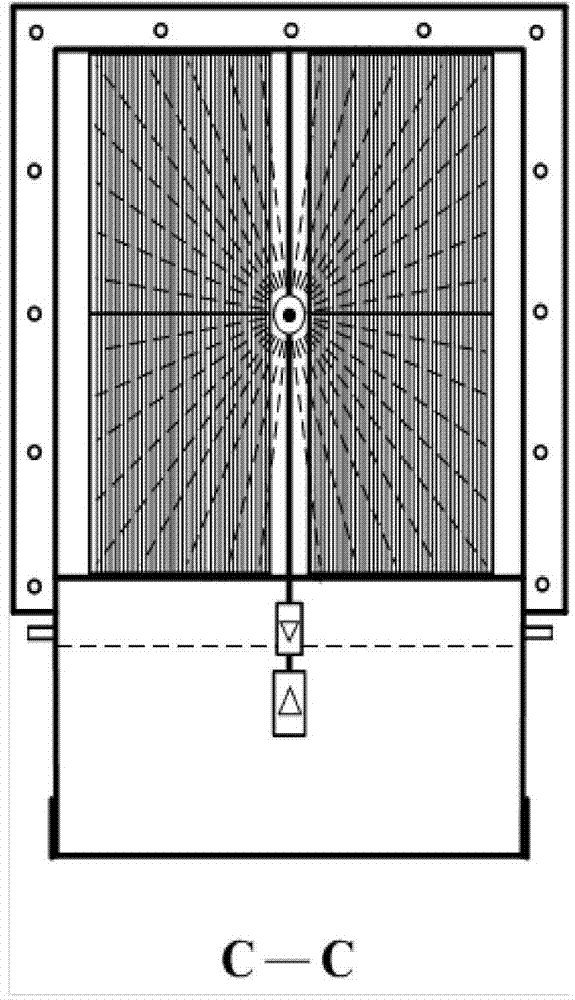

[0022] The present invention is further described as follows in conjunction with accompanying drawing:

[0023] Such as figure 1 , 2 As shown in and 3, a grid plate fixing frame 2, a spray head fixing frame 4 and a liquid remover 15 are welded on the wet type intensive grid filter purifier box 1, and the dense grid plate 3 is inserted on the grid plate fixing frame 2, and the spraying The head 5 is installed on the spray head fixing frame 4; the spray head 5, the flow meter 7, the liquid supply pump 8 and the liquid collection tank 9 are connected in turn through the liquid supply pipe 6; A liquid injection port 10, a filter screen 11, a dredging port 12 and a sealing plate 13 are housed in the liquid tank 9, and two strip discharge ports 14 are arranged between the liquid collecting tank 9 and the casing 1. When filtering and purifying the polluted airflow, the liquid supply pump 8 draws the cleaning liquid from the liquid collection tank 9 filled with the cleaning liquid t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com